Anschluss mit Hydraulikflanschen

- Rechteckflansche vom Typ ISO 6162-1 und 2/SAE

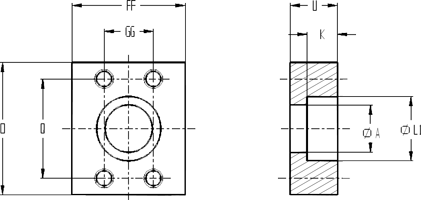

- Quadratflansche vom Typ CETOP oder SID./ ISO 6164

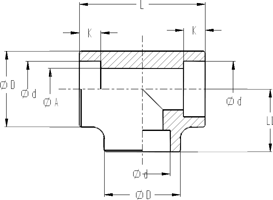

Prinzip:

Das System besteht einer komprimierbaren Dichtung die zwischen zwei parallel angeordneten Flächen eingelegt, fest angedrückt und mittels verschraubter Flanche zusammengehalten wird.

Zentriert wird die Dichtung anhand einer kreisförmigen Nut, in der sie eingelegt wird.

Bei Verbindungsflanschen entsprechen beide Flächen den Bördelkanten (eine mit und die andere ohne Dichtung).

Bei Befestigungsflanschen entsprechen die Flächen einerseits der Bördelkante mit Dichtung und andererseits dem Außenteil der abzudichtenden Hydraulikvorrichtung (Motor, Pumpe, Zylinder usw.).

Vorteile der SAE-Flansche:

- Anschluss von Rohren mit einem Außendurchmesser bis 5“ (ISO 6162-1, SAE J518 Code).

- Für die Befestigung der Schrauben sind sehr viel geringere Anzugsmomente erforderlich, als bei gleichwertigen Gewindekupplungen.

- Niedrige Anzugsmomente können auch mit kleinen Maulschlüsseln erreicht werden, die in engen Einbausituationen deutliche Vorteile bieten.

- Anwendungen bis zu 420 bar (6000 PSI) für Flanschgrößen von 1/2˝ bis 2˝ (ISO 6162-2, SAE J518 Code 62).

- Ein einziger Abdichtungspunkt zwischen dem Rohr/Schlauch und der Flanschkupplung.

- Einfache Demontage durch die Verwendungen von Halbflanschen.

Werkstoffe

- Ein- oder zweiteilige Rechteckflansche: Schmiedestahl S 355** (E 36-3 / St 52-3), auf Anfrage Edelstahl AISI 316

- Quadratflansche Typ CETOP und Sid. : Stahl S 355**, auf Anfrage Edelstahl 304L (1.4306) oder 316L (1.4404)

- ISO-/SAE-Blöcke: Stahl C35/C45 (XC38/48 - CK35/45), auf Anfrage Edelstahl 304L (1.4306) oder 316L (1.4404)

- Schweißflansche: Stahl S 235** (E 24 / St 37)

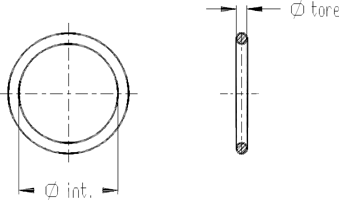

- Standard-O-Ringe: Perbunan / Viton 90 Shore A

- Verschlüsse: Stahl S 235** (E 24 / St 37)

- Gewindeflansche: Stahl S 235** (E 24 / St 37)

- Metrische/UNC CHC-Schrauben: Vergütungsstahl Klasse 12.9

- Muttern: Vergütungsstahl Klasse 10

Normierung

RECHTECKFLANSCHE UND SCHWEISSFLANSCHE | NORM ISO (NORM AFNOR) NORM U.S.A. | ISO 6162-1 und 2 von 2002 ( NF E 48-055 12/86 ) SAE J 518 | ||

QUADRATFLANSCHE UND SCHWEISSFLANSCHE | AFNOR EMPFEHLUNG | NF E 48-054 12/98 CETOP RP 63 H ISO 6164 05/94 | ||

VMETRISCHE SCHRAUBEN | AFNOR DIN U.S.A. | NF EN ISO 4762 12/97 912 Nach amerikanischem Standard | ||

O-RINGE | USA AFNOR | SAE J 515 NF T 47 501 04/98 | ||

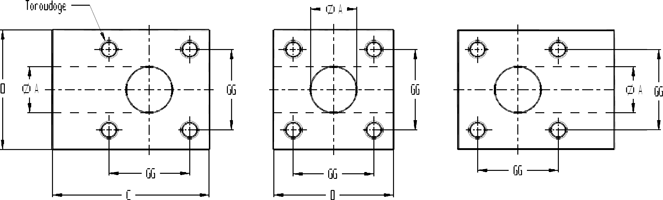

Flanschtypen

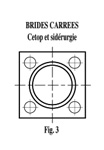

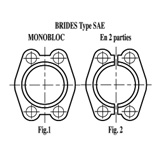

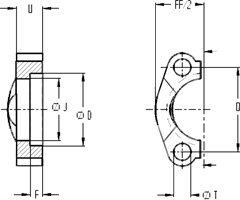

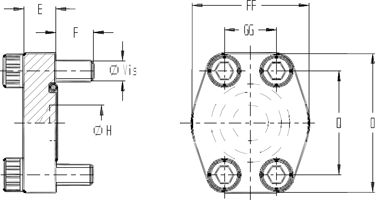

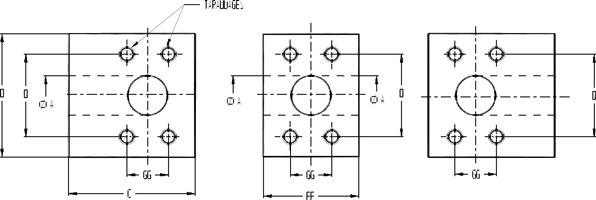

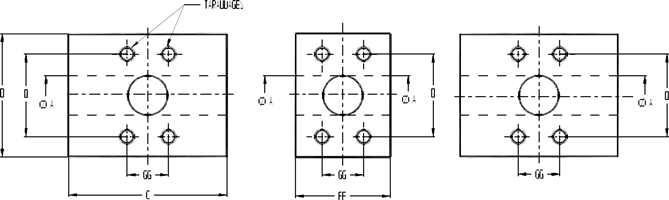

| Quadratflansche vom Typ CETOP oder SID./ ISO 6164 (Abb. 3) |

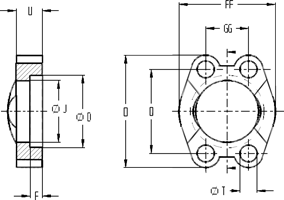

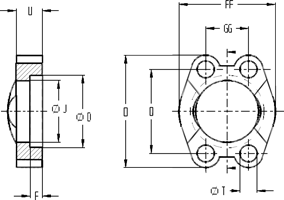

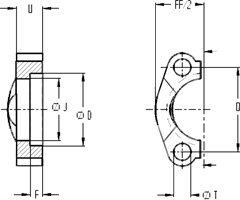

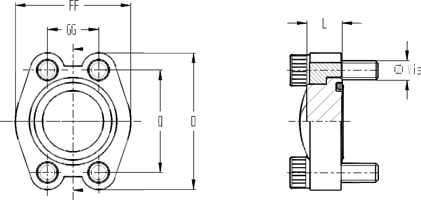

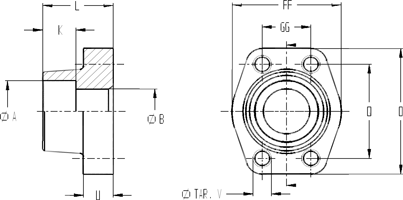

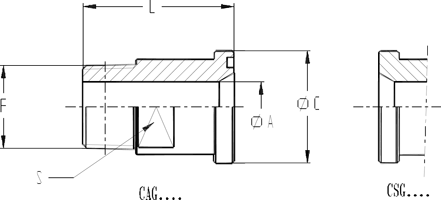

| Rechteckflansche vom Typ ISO 6162-1 und 2/SAE (Abb. 1 und 2) |

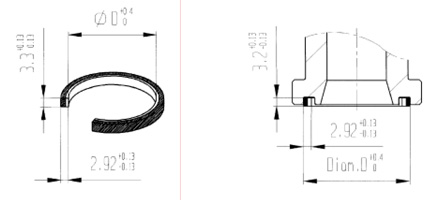

Oberflächengüte

| Flansche | Schweißflansche |

Außenflächen roh Innenflächen Ra = 6,3 Bohrung Ra = 6,3 | Alle Außenprofile Ra = 6,3 Durchgang Ra = 6,3 Dichtflächen und Nuten Ra = 1,6 |

Schutz

- Flansche und Halbflansche: Verzinkt gemäß ISO 6162 / SAE

- Quadratflansche: Phosphatiert oder geölt

- Druckflansche: Verzinkt gemäß ISO 6162 / 6164

- Schweißflansche und Verschlüsse: Geölt oder phosphatiert

- Gewindeflansche: Verzinkt mit Bichromatschutz

- Schrauben: Brüniert

- Anschlussblöcke: Geölt

Anzugsmomente

METRISCHE SCHRAUBEN

| Schraubendurchmesser | M 6 | M 8 | M 10 | M 12 | M 14 | M 16 | M 18 | M 20 | M 22 | M 24 | M 27 | ||

| Max. Anzugsmoment da Nm | 1 | 3,2 | 7 | 13 | 14,9 | 23 | 32 | 45 | 61 | 71 | 110 | ||

UNC SCHRAUBEN

| Schraubendurchmesser | 5/16" | 3/8" | 7/16" | 1/2" | 5/8" | 3/4" |

| Max. Anzugsmoment da Nm | 3,5 | 6,3 | 10 | 15,6 | 30 | 49 |

Die folgenden Anzugsmomente sind lediglich Referenzwerte.

Abdichtung

Die Abdichtung der Kupplungen wird bei Standardmodellen durch O-Ringe aus Perbunan mit einer Härte von 90 Shore erreicht.

Die Wahl der Dichtung wird vom Fördermedium und der Betriebstemperatur bedingt.

| Fördermedien | Betriebstemperatur | Werkstoff | ||

| Mineralöle, Wasser mit löslichen Ölen | - 30° + 110° C | PERBUNAN | ||

| Nicht brennbare Hydraulikflüssigkeiten, Hochtemperaturöle | - 20 ° + 200° C | VITON* ELASTOMERE FLUORE | ||

Weitere Medien oder andere Temperaturen auf Anfrage

* Eingetragene Marke von Dupont de Nemours.

Rechteckflansche – Reihen 3000/6000

Flansche

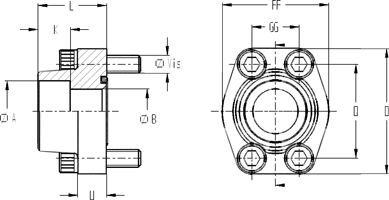

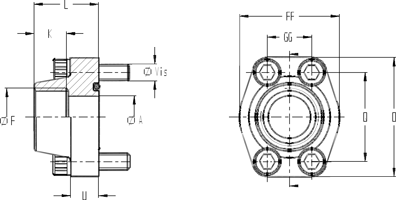

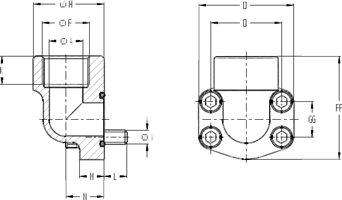

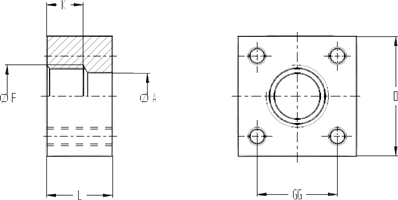

EINTEILIGE RECHTECKFLANSCHE - SAE 3000 / SAE 6000

| EINTEILIGE RECHTECKFLANSCHE gemäß ISO 6162-1 / SAE 3000 | |||||||||||||

| REF. | PN bar1 | DN | F | Ø D | Ø J | U | Ø T | GG | Q | FF | O | Schrauben | |

| M | UNC | ||||||||||||

| BM-3000-3/8"-M | 350 | 10 | 6.2 | 24.9 | 18.7 | 14 | 8.7 | 16.5 | 35 | 40 | 50 | 8 | - |

| BM-3000-1/2"-M/U | 350 | 13 | 6.2 | 31 | 24.3 | 13 | 8.7 | 17.5 | 38.1 | 46 | 4 | 8 | 5/16" |

| BM-3000-3/4"-M/U | 350 | 19 | 6.2 | 38.9 | 32.2 | 14 | 10.5 | 22.3 | 47.6 | 52 | 65 | 10 | 3/8" |

| BM-3000-1"-M/U | 315 | 25 | 7.5 | 45.3 | 38.5 | 16 | 10.5 | 26.2 | 52.4 | 59 | 70 | 10 | 3/8" |

| BM-3000-1"1/4-U | 250 | 32 | 7.5 | 51.6 | 43.7 | 14 | 12 | 30.2 | 58.7 | 73 | 79.5 | - | 7/16" |

| BM-3000-1"1/4-M | 250 | 32 | 7.5 | 51.6 | 43.7 | 14 | 12.5 | 30.2 | 58.7 | 73 | 79.5 | 12 | - |

| BM-3000-1"1/4"-M/ISO* | 250 | 32 | 7.5 | 51.6 | 43.7 | 14 | 10.5 | 30.2 | 58.7 | 73 | 79.5 | 10 | - |

| BM-3000-1"1/2-U/ISO* | 200 | 38 | 7.5 | 61.1 | 50.8 | 16 | 13.5 | 35.7 | 69.8 | 83 | 94 | 12 | 1/2" |

| BM-3000-1"1/2-M | 200 | 38 | 7.5 | 61.1 | 50.8 | 16 | 14.5 | 35.7 | 69.8 | 83 | 94 | 14 | - |

| BM-3000-2"-U/ISO* | 200 | 51 | 9 | 72.3 | 62.8 | 16 | 13.5 | 42.9 | 77.8 | 97 | 102 | 12 | 1/2" |

| BM-3000-2"-M | 200 | 51 | 9 | 72.3 | 62.8 | 16 | 14.5 | 42.9 | 77.8 | 97 | 102 | 14 | - |

| BM-3000-2"1/2-U/ISO* | 160 | 64 | 9 | 84.9 | 74.9 | 19 | 13.5 | 50.8 | 88.9 | 109 | 114.5 | 12 | 1/2" |

| BM-3000-2"1/2-M | 160 | 64 | 9 | 84.9 | 74.9 | 19 | 14.5 | 50.8 | 88.9 | 109 | 114.5 | 14 | - |

| BM-3000-3"-M/U | 138 | 76 | 9 | 102.4 | 90.9 | 22 | 17 | 61.9 | 106.4 | 131 | 135 | 16 | 5/8" |

| BM-3000-3"1/2-M/U | 35 | 89 | 10.7 | 115.1 | 102.4 | 22 | 17 | 69.8 | 120.7 | 140 | 152 | 16 | 5/8" |

| BM-3000-4"-M/U | 35 | 102 | 10.7 | 127.8 | 115 | 25 | 17 | 77.8 | 130.2 | 152 | 162 | 16 | 5/8" |

| (1) Empfohlener Höchstdruck Manche Flansche können beliebig mit metrischen (M) oder UNC-Schrauben befestigt werden. Die Art.-Nr. Endet dann jeweils auf M/U oder U/ISO. Andere Flanschs sind nur für metrische Schrauben oder nur UNC-Schrauben geeignet. Die Art.-Nr. Endet dann jeweils auf M oder U. * Gemäß ISO 6162-1 (verschiedene Schraubendurchmesser) | |||||||||||||

| EINTEILIGE RECHTECKFLANSCHE gemäß ISO 6162-1 / SAE 6000 | |||||||||||||

| REF. | PN bar1 | DN | F | Ø D | Ø J | U | Ø T | GG | Q | FF | O | Schrauben | |

| M | UNC | ||||||||||||

| BM-6000-1/2"-M/U | 400 | 13 | 7.2 | 32.5 | 24.6 | 16 | 8.7 | 18.2 | 40.5 | 48 | 56.5 | 8 | |

| BM-6000-3/4"-M/U | 400 | 19 | 8.2 | 42 | 32.5 | 19 | 10.5 | 23.8 | 50.8 | 60 | 71 | 10 | 5/16" 3/8" |

| BM-6000-1"-U | 400 | 25 | 9 | 48.4 | 38.8 | 24 | 12 | 27.8 | 57.2 | 70 | 81 | - | 7/16" |

| BM-6000-1"-M | 400 | 25 | 9 | 48.4 | 38.8 | 24 | 13 | 27.8 | 57.2 | 70 | 81 | 12 | - |

| BM-6000-1"1/4-U / ISO* | 400 | 32 | 9.8 | 54.8 | 44.5 | 27 | 13.5 | 31.8 | 66.6 | 78 | 95 | 12 | 1/2" |

| BM-6000-1"1/4/M | 400 | 32 | 9.8 | 54.8 | 44.5 | 27 | 15 | 31.8 | 66.6 | 78 | 95 | 14 | - |

| BM-6000-1"1/2-M/U | 400 | 38 | 12 | 64.3 | 51.6 | 30 | 17 | 36.5 | 79.3 | 95 | 113 | 16 | 5/8" |

| BM-6000-2"-M / U / ISO | 400 | 51 | 12 | 80.2 | 67.6 | 37 | 21 | 44.5 | 96.8 | 114 | 133 | 20 | 3/4" |

| (1) Empfohlener Höchstdruck Manche Flansche können beliebig mit metrischen (M) oder UNC-Schrauben befestigt werden. Die Art.-Nr. Endet dann jeweils auf M/U oder U/ISO. Andere Flanschs sind nur für metrische Schrauben oder nur UNC-Schrauben geeignet. Die Art.-Nr. Endet dann jeweils auf M oder U. * Gemäß ISO 6162-1 (verschiedene Schraubendurchmesser) | |||||||||||||

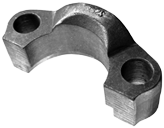

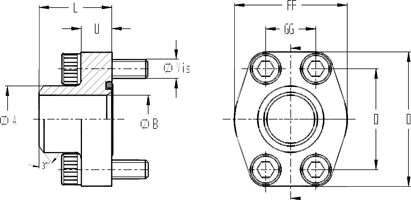

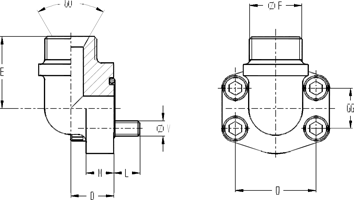

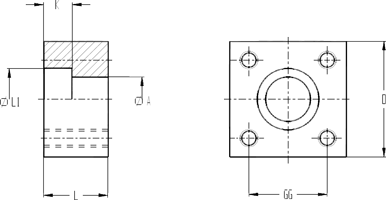

HALBE RECHTECKFLANSCHE - SAE 3000 / SAE 6000

| HALBE RECHTECKFLANSCHE gemäß ISO 6162-1 / SAE 3000 | |||||||||||||

| REF. | PN bar1 | DN | F | Ø D | Ø J | U | Ø T | GG/2 | Q | FF/2 | O | Schrauben | |

| M | UNC | ||||||||||||

| DB-3000-1/2"-M/U | 350 | 13 | 6.2 | 31 | 24.3 | 13 | 8.7 | 8.75 | 38.1 | 22.8 | 54 | 8 | 5/16" |

| DB-3000-3/4"-M/U | 350 | 19 | 6.2 | 38.9 | 32.2 | 14 | 10.5 | 11.15 | 47.6 | 25.9 | 65 | 10 | 3/8" |

| DB-3000-1"-M/U | 315 | 25 | 7.5 | 45.3 | 38.5 | 16 | 10.5 | 13.1 | 52.4 | 29.2 | 70 | 10 | 3/8" |

| DB-3000-1"1/4-U | 250 | 32 | 7.5 | 51.6 | 43.7 | 14 | 12 | 15.1 | 58.7 | 36.3 | 79.5 | - | 7/16" |

| DB-3000-1"1/4-M | 250 | 32 | 7.5 | 51.6 | 43.7 | 14 | 12.5 | 15.1 | 58.7 | 36.3 | 79.5 | 12 | - |

| DB-3000-1"1/4"/ISO* | 250 | 32 | 7.5 | 51.6 | 43.7 | 14 | 10.5 | 15.1 | 58.7 | 36.3 | 79.5 | 10 | - |

| DB-3000-1"1/2-U/ISO* | 200 | 38 | 7.5 | 61.1 | 50.8 | 16 | 13.5 | 17.85 | 69.8 | 41.1 | 94 | 12 | 1/2" |

| DB-3000-1"1/2-M | 200 | 38 | 7.5 | 61.1 | 50.8 | 16 | 14.5 | 17.85 | 69.8 | 41.1 | 94 | 14 | - |

| DB-3000-2"-U/ISO* | 200 | 51 | 9 | 72.3 | 62.8 | 16 | 13.5 | 21.45 | 77.8 | 48.2 | 102 | 12 | 1/2" |

| DB-3000-2"-M | 200 | 51 | 9 | 72.3 | 62.8 | 16 | 14.5 | 21.45 | 77.8 | 48.2 | 102 | 14 | - |

| DB-3000-2"1/2-U/ISO* | 160 | 64 | 9 | 84.9 | 74.9 | 19 | 13.5 | 25.4 | 88.9 | 54.1 | 114.5 | 12 | 1/2" |

| DB-3000-2"1/2/M | 160 | 64 | 9 | 84.9 | 74.9 | 19 | 14.5 | 25.4 | 88.9 | 51.4 | 114.5 | 14 | - |

| DB-3000-3"-M/U | 138 | 76 | 9 | 102.4 | 90.9 | 22 | 17 | 30.95 | 106.4 | 65.3 | 135 | 16 | 5/8" |

| DB-3000-3"1/2-M/U | 35 | 89 | 10.7 | 115.1 | 102.4 | 22 | 17 | 34.95 | 120.7 | 69.6 | 152 | 16 | 5/8" |

| DB-3000-4"-M/U | 35 | 102 | 10.7 | 127.8 | 115 | 25 | 17 | 38.9 | 130.2 | 75.9 | 162 | 16 | 5/8" |

| (1) Empfohlener Höchstdruck Manche Flansche können beliebig mit metrischen (M) oder UNC-Schrauben befestigt werden. Die Art.-Nr. Endet dann jeweils auf M/U oder U/ISO. Andere Flanschs sind nur für metrische Schrauben oder nur UNC-Schrauben geeignet. Die Art.-Nr. Endet dann jeweils auf M oder U. * Gemäß ISO 6162-1 (verschiedene Schraubendurchmesser) | |||||||||||||

| HALBE RECHTECKFLANSCHE gemäß ISO 6162-2 / SAE 6000 | |||||||||||||

| REF. | PN bar1 | DN | F | Ø D | Ø J | U | Ø T | GG/2 | Q | FF/2 | O | Schrauben | |

| M | UNC | ||||||||||||

| DB-6000-1/2"-M/U | 400 | 13 | 7.2 | 32.5 | 24.6 | 16 | 8.7 | 9.1 | 40.5 | 23.6 | 56.5 | 8 | 5/16" |

| DB-6000-3/4"-M/U | 400 | 19 | 8.2 | 42 | 32.5 | 19 | 10.5 | 11.9 | 50.8 | 30 | 71 | 10 | 3/8" |

| DB-6000-1"-U | 400 | 25 | 9 | 48.4 | 38.8 | 24 | 12 | 13.85 | 57.1 | 34.8 | 81 | - | 7/16" |

| DB-6000-1"-M | 400 | 25 | 9 | 48.4 | 38.8 | 24 | 13 | 13.85 | 57.1 | 34.8 | 81 | 12 | - |

| DB-6000-1"1/4-U / ISO* | 400 | 32 | 9.8 | 54.8 | 44.5 | 27 | 13.5 | 15.85 | 66.7 | 38.6 | 95 | 12 | 1/2" |

| DB-6000-1"1/4-M | 400 | 32 | 9.8 | 54.8 | 44.5 | 27 | 15 | 15.85 | 66.7 | 38.6 | 95 | 14 | - |

| DB-6000-1"1/2-M/U | 400 | 38 | 12 | 64.3 | 51.6 | 30 | 17 | 18.25 | 79.4 | 47.5 | 113 | 16 | 5/8" |

| DB-6000-2"-M / U / ISO | 400 | 51 | 12 | 80.2 | 67.6 | 37 | 21 | 22.2 | 96.8 | 56.9 | 133 | 20 | 3/4" |

| (1) Empfohlener Höchstdruck Manche Flansche können beliebig mit metrischen (M) oder UNC-Schrauben befestigt werden. Die Art.-Nr. Endet dann jeweils auf M/U oder U/ISO. Andere Flanschs sind nur für metrische Schrauben oder nur UNC-Schrauben geeignet. Die Art.-Nr. Endet dann jeweils auf M oder U. * Gemäß ISO 6162-1 (verschiedene Schraubendurchmesser) | |||||||||||||

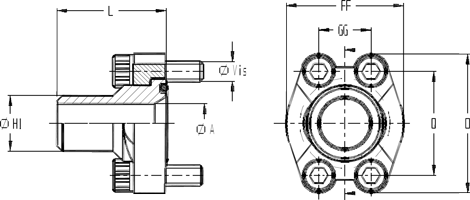

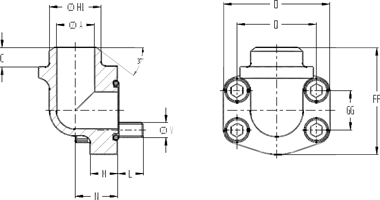

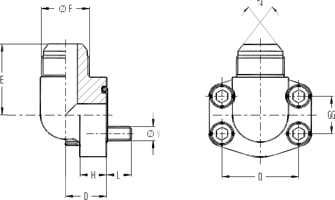

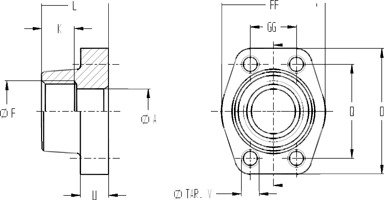

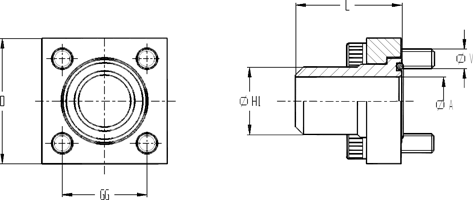

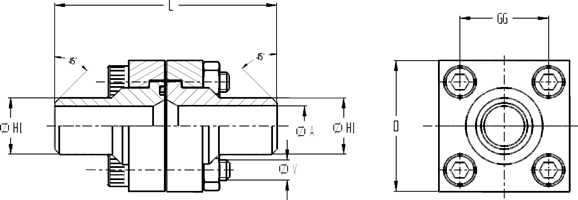

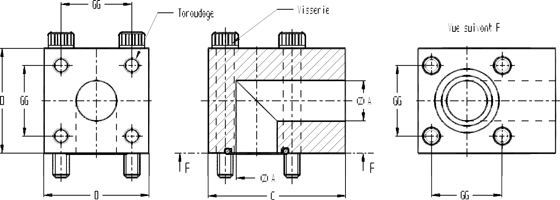

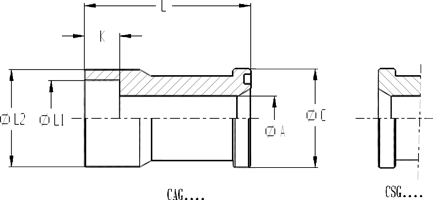

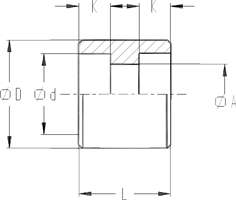

Befestigungsflansche

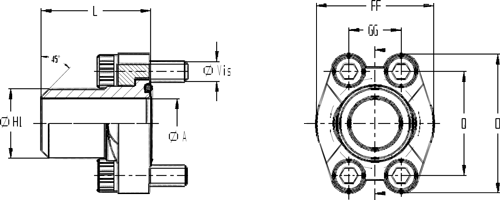

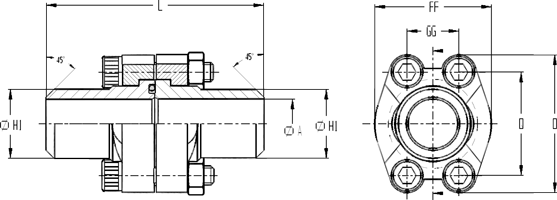

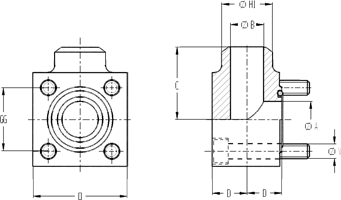

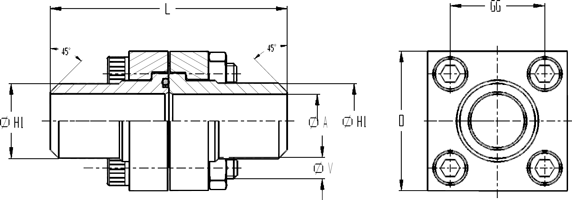

BEFESTIGUNGSFLANSCHE BWI MIT VOLLDURCHGANG - SAE 3000 / SAE 6000

| BEFESTIGUNGSFLANSCHE BWI MIT VOLLDURCHGANG S.A.E. 3000 / ISO 6162-1 | ||||||||||||

| REF. | PN bar1 | DN | Außen-Ø Rohr von... bis | Ø A | Ø H1 | L | FF | O | GG | Q | Schrauben | |

| M | UNC | |||||||||||

| BFX-3000-BWI-3/8 | 350 | 10 | 14-18 | 12 | 18 | 40 | 40 | 50 | 16.5 | 35 | M 8X30 | |

| BFX-3000-BWI-1/2 | 350 | 13 | 18-22 | 13 | 22 | 45 | 46 | 54 | 17.5 | 38.1 | M 8X25 | 5/16-11/4 |

| BFX-3000-BWI-3/4 | 350 | 19 | 25-28 | 19 | 28 | 50 | 52 | 65 | 22.3 | 47.6 | M 10X30 | 3/8-11/4 |

| BFX-3000-BWI-1 | 315 | 25 | 30-35 | 25 | 35 | 55 | 59 | 70 | 26.2 | 52.4 | M 10X30 | 3/8-11/4 |

| BFX-3000-BWI-11/4 * | 250 | 32 | 38-43 | 32 | 43 | 60 | 73 | 79.5 | 30.2 | 58.7 | M 12X30* | 7/16-11/2 |

| BFX-3000-BWI-11/2 * | 210 | 38 | 48-50 | 38 | 50 | 65 | 83 | 94 | 35.7 | 69.8 | M 14X35* | 1/2-11/2 |

| BFX-3000-BWI-2 * | 51 | 60-63 | 47 | 61.8 | 70 | 97 | 102 | 42.9 | 77.8 | M 14X35* | 1/2-11/2 | |

| 160 | ||||||||||||

| BFX-3000-BWI-21/2 * | 160 | 64 | 73-76 | 58 | 74 | 75 | 109 | 114.5 | 50.8 | 88.9 | M 14X40* | 1/2-13/4 |

| BFX-3000-BWI-3 | 138 | 76 | 88-90 | 70 | 90 | 85 | 131 | 135 | 61.9 | 106.4 | M 16X50 | 5/8-13/4 |

| BFX-3000-BWI-31/2 | 35 | 89 | 95-102 | 86 | 102 | 90 | 140 | 152 | 69.8 | 120.7 | M 16X50 | 5/8-2 |

| BFX-3000-BWI-4 | 35 | 102 | 113-120 | 96 | 114 | 100 | 152 | 162 | 77.8 | 130.2 | M 16X50 | 5/8-2 |

(1) Empfohlener Höchstdruck | ||||||||||||

| BEFESTIGUNGSFLANSCHE BWI MIT VOLLDURCHGANG S.A.E. 6000 / ISO 6162-2 | ||||||||||||

| REF. | PN bar1 | DN | Außen-ØRohr von... bis | Ø A | Ø H1 | L | FF | O | GG | Q | Schrauben | |

| M | UNC | |||||||||||

| BFX-6000-BWI-1/2 | 400 | 13 | 20-22 | 13 | 22 | 45 | 48 | 56.5 | 18.2 | 40.5 | M 8X30 | 5/16-11/4 |

| BFX-6000-BWI-3/4 | 400 | 19 | 25-28 | 17.5 | 28 | 50 | 60 | 71 | 23.8 | 50.8 | M 10X35 | 3/8-11/2 |

| BFX-6000-BWI-1 | 400 | 25 | 30-35 | 22 | 35 | 55 | 70 | 81 | 27.8 | 57.2 | M 12X45 | 7/16-13/4 |

| BFX-6000-BWI-11/4* | 400 | 32 | 38-43 | 29 | 43.8 | 60 | 78 | 95 | 31.8 | 66.6 | M 14X50* | 1/2-13/4 |

| BFX-6000-BWI-11/2 | 400 | 38 | 48-52 | 35 | 50.6 | 65 | 95 | 113 | 36.5 | 79.3 | M 16X55 | 5/8-21/4 |

| BFX-6000-BWI-2 | 400 | 51 | 60-65 | 43 | 65 | 70 | 114 | 133 | 44.5 | 96.8 | M 20X70 | 3/4-23/4 |

(1) Empfohlener Höchstdruck | ||||||||||||

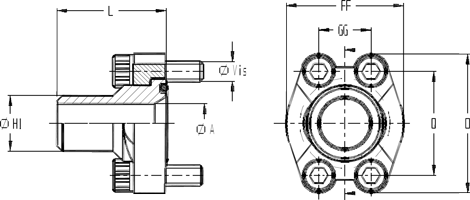

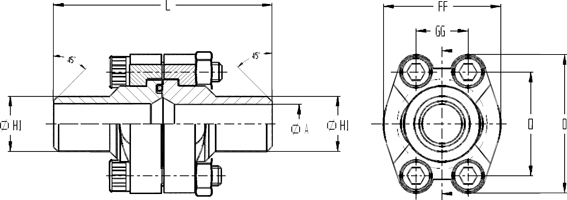

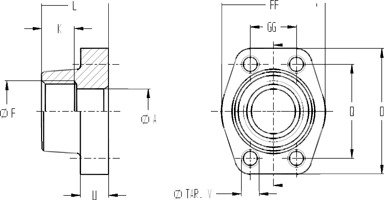

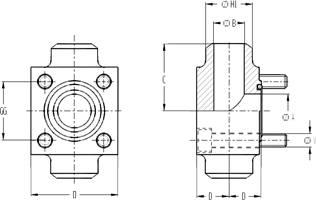

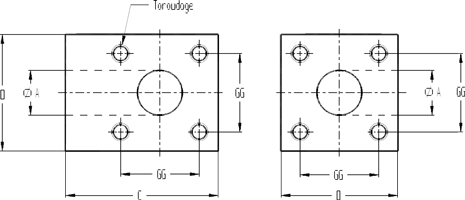

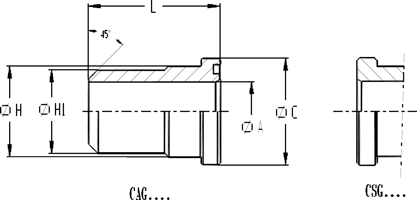

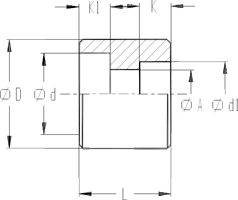

BEFESTIGUNGSFLANSCHE BWR MIT TEILDURCHGANG - SAE 3000 / SAE 6000

| BEFESTIGUNGSFLANSCHE BWR MIT TEILDURCHGANG S.A.E. 3000 / ISO 6162-1 | ||||||||||||

| REF. | PN bar1 | DN | Außen-Ø Rohr von... bis | Ø A | Ø H1 | L | FF | O | GG | Q | Schrauben | |

| M | UNC | |||||||||||

| BFX-3000-BWR-1/2 | 350 | 13 | 16-18 | 12 | 18 | 45 | 46 | 54 | 17.5 | 38.1 | M 8X25 | 5/16-11/4 |

| BFX-3000-BWR-3/4 | 350 | 19 | 18-22 | 13 | 22 | 50 | 52 | 65 | 22.3 | 47.6 | M 10X30 | 3/8-11/4 |

| BFX-3000-BWR-1 | 315 | 25 | 25-28 | 19 | 28 | 55 | 59 | 70 | 26.2 | 52.4 | M 10X30 | 3/8-11/4 |

| BFX-3000-BWR-11/4 * | 250 | 32 | 30-35 | 25 | 35 | 60 | 73 | 79.5 | 30.2 | 58.7 | M 12X30* | 7/16-11/2 |

| BFX-3000-BWR-11/2 * | 210 | 38 | 38-43 | 32 | 43 | 65 | 83 | 94 | 35.7 | 69.8 | M 14X35* | 1/2-11/2 |

| BFX-3000-BWR-2 * | 210 | 51 | 48-50 | 38 | 50 | 70 | 97 | 102 | 42.9 | 77.8 | M 14X35* | 1/2-11/2 |

| BFX-3000-BWR-21/2 * | 160 | 64 | 60-63 | 47 | 61.8 | 75 | 109 | 114.5 | 50.8 | 88.9 | M 14X40* | 1/2-13/4 |

| BFX-3000-BWR-3 | 138 | 76 | 73-76 | 58 | 74 | 85 | 131 | 135 | 61.9 | 106.4 | M 16X50 | 5/8-13/4 |

| BFX-3000-BWR-31/2 | 35 | 89 | 88-90 | 70 | 90 | 90 | 140 | 152 | 69.8 | 120.7 | M 16X50 | 5/8-2 |

| BFX-3000-BWR-4 | 35 | 102 | 95-102 | 80 | 102 | 100 | 152 | 162 | 77.8 | 130.2 | M 16X50 | 5/8-2 |

(1) Empfohlener Höchstdruck | ||||||||||||

| BEFESTIGUNGSFLANSCHE BWR MIT TEILDURCHGANG S.A.E. 6000 / ISO 6162-2 | ||||||||||||

| REF. | PN bar1 | DN | Außen-Ø Rohr von... bis | Ø A | Ø H1 | L | FF | O | GG | Q | Schrauben | |

| M | UNC | |||||||||||

| BFX-6000-BWR-1/2 | 400 | 13 | 16-18 | 11 | 17.5 | 45 | 48 | 56.5 | 18.2 | 40.5 | M 8X30 | 5/16-11/4 |

| BFX-6000-BWR-3/4 | 400 | 19 | 20-22 | 13 | 22 | 50 | 60 | 71 | 23.8 | 50.8 | M 10X35 | 3/8-11/2 |

| BFX-6000-BWR-1 | 400 | 25 | 25-28 | 17.5 | 28 | 55 | 70 | 81 | 27.8 | 57.2 | M 12X45 | 7/16-13/4 |

| BFX-6000-BWR-11/4* | 400 | 32 | 30-35 | 22 | 35 | 60 | 78 | 95 | 31.8 | 66.6 | M 14X50* | 1/2-13/4 |

| BFX-6000-BWR-11/2 | 400 | 38 | 38-43 | 29 | 43.8 | 65 | 95 | 113 | 36.5 | 79.3 | M 16X55 | 5/8-21/4 |

| BFX-6000-BWR-2 | 400 | 51 | 48-50 | 35 | 51 | 70 | 114 | 133 | 44.5 | 96.8 | M 20X70 | 3/4-23/4 |

(1) Empfohlener Höchstdruck | ||||||||||||

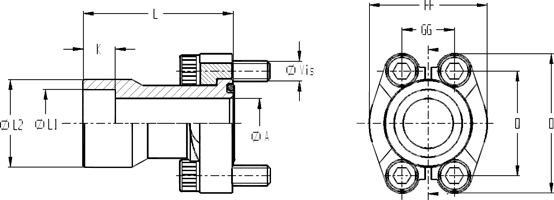

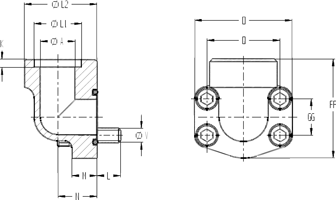

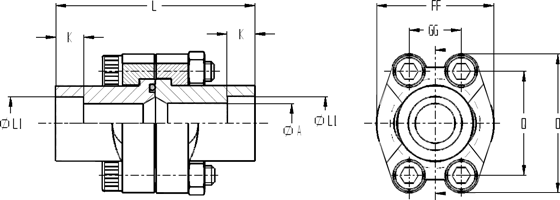

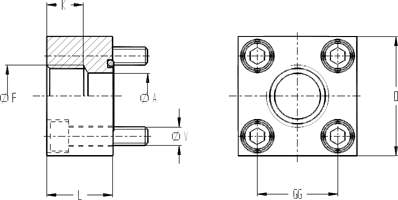

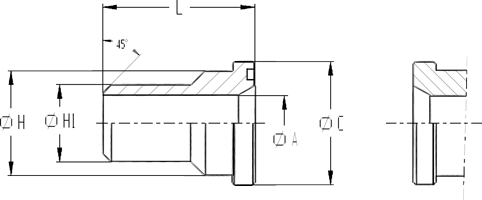

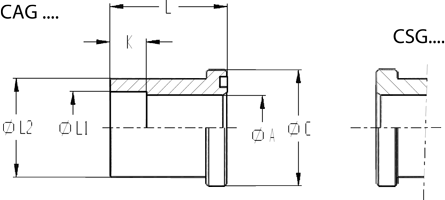

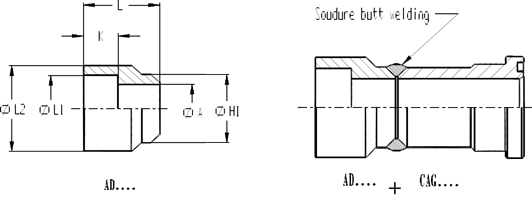

BEFESTIGUNGSFLANSCHE SOCKET WELDING MIT VOLLDURCHGANG - SAE 3000 / SAE 6000

| BEFESTIGUNGSFLANSCHE „SOCKET WELDING“ MIT VOLLDURCHGANG S.A.E. 3000 / ISO 6162-1 | ||||||||||||||||||||||||||||

| REF. | PN bar1 | DN | Außen-Ø Rohr | Ø L1 | Ø L2 | ØA | K | L | GG | Q | FF | O | Schrauben | |||||||||||||||

| MM | GAZ | SCHD | M | UNC | ||||||||||||||||||||||||

| BFX-3000-SWI-1/2"-20.5 BFX-3000-SWI-1/2"-21.7 | 315 | 13 | 20 | 21.25 | 21.34 | 20.5 21.7 | 30 | 13 | 13 | 60 | 17.5 | 38.1 | 46 | 54 | M 8X25 | 5/16-1"1/4 | ||||||||||||

| BFX-3000-SWI-3/4"-25.5 BFX-3000-SWI-3/4"-27.3 | 19 | 25 | 26.75 | 26.68 | 25.5 27.3 | 35 | 19 | 13 | 68 | 22.3 | 47.6 | 52 | 65 | M 10X30 | 3/8-1"1/4 | |||||||||||||

| BFX-3000-SWI-1"-30.5 BFX-3000-SWI-1"-32.5 BFX-3000-SWI-1"-34 BFX-3000-SWI-1"-35.5 | 25 | 30 32 35 | 33.50 | 33.40 | 30.5 32.5 34 35.5 | 44 | 25 | 16 | 75 | 26.2 | 52.4 | 59 | 70 | M 10X30 | 3/8-1"1/4 | |||||||||||||

| BFX-3000-SWI-1"1/4-38.5* BFX-3000-SWI-1"1/4-40.5* BFX-3000-SWI-1"1/4-43* | 200 | 32 | 38 40 42 | 42.25 | 42.16 | 38.5 40.5 43 | 55 | 32 | 18 | 95 | 30.2 | 58.7 | 73 | 79.5 | M 12X30* | 716-1"1/2 | ||||||||||||

| BFX-3000-SWI-1"1/2-49* BFX-3000-SWI-1"1/2-50.4* | 38 | 50 | 48.25 | 48.26 | 49 50.4 | 63 | 38 | 20 | 100 | 35.7 | 69.8 | 83 | 94 | M 14X35* | 1/2-1"1/2 | |||||||||||||

| BFX-3000-SWI-2"-61 * BFX-3000-SWI-2"-65.8 * | 51 | 60 65 | 60.30 | 60.32 | 61 65.8 | 79 | 47 | 22 | 107 | 42.9 | 77.8 | 97 | 102 | M 14X35* | 1/2-1"1/2 | |||||||||||||

| BFX-3000-SWI-2"1/2-74* BFX-3000-SWI-2"1/2-77* BFX-3000-SWI-2"1/2-81* | 150 | 64 | 80 | 76.10 | 73.02 | 74 77 81 | 98 | 58 | 24 | 130 | 50.8 | 88.9 | 109 | 114.5 | M 14X40* | 1/2-1"3/4 | ||||||||||||

| BFX-3000-SWI-3"-90.5 | 100 | 76 | 90 | 88.90 | 90.5 | 116 | 70 | 28 | 150 | 61.9 | 106.4 | 131 | 135 | M 16X50 | 5/8-1"3/4 | |||||||||||||

(1) Empfohlener Höchstdruck | ||||||||||||||||||||||||||||

| BEFESTIGUNGSFLANSCHE „SOCKET WELDING“ MIT VOLLDURCHGANG S.A.E. 6000 / ISO 6162-2 | ||||||||||||||||||||||||||||

| REF. | PN bar1 | DN | Außen-Ø Rohr | Ø L1 | Ø L2 | ØA | K | L | GG | Q | FF | O | Schrauben | |||||||||||||||

| MM | GAZ | SCHD | M | UNC | ||||||||||||||||||||||||

| BFX-6000-SWI-1/2"-20.5 BFX-6000-SWI-1/2"-21.7 BFX-6000-SWI-1/2"-22.5 | 380 | 13 | 20 22 | 21.25 | 21.34 | 20.5 21.7 22.5 | 32 | 13 | 13 | 60 | 18.2 | 40.5 | 48 | 56.5 | M 8X30 | 5/16-1"1/4 | ||||||||||||

| BFX-6000-SWI-3/4"-25.7 BFX-6000-SWI-3/4"-27.3 BFX-6000-SWI-3/4"-28.7 | 19 | 25 28 | 26.75 | 26.68 | 25.7 27.3 28.7 | 40 | 17. 5 | 13 | 68 | 23.8 | 50.8 | 60 | 71 | M 10X35 | 3/8-1"1/2 | |||||||||||||

| BFX-6000-SWI-1"-34 BFX-6000-SWI-1"-35.5 | 25 | 35 | 33.5 | 33.4 | 34 35.5 | 48 | 22 | 16 | 75 | 27.8 | 57.2 | 70 | 81 | M 12X45 | 7/16-1"3/4 | |||||||||||||

(1) Empfohlener Höchstdruck | ||||||||||||||||||||||||||||

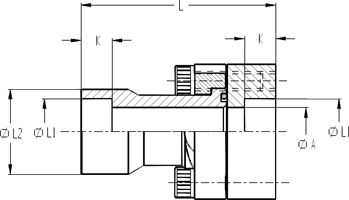

BEINTEILIGE BEFESTIGUNGSFLANSCHE SOCKET WELDING MIT VOLLDURCHGANG - SAE 3000 / SAE 6000

| BEINTEILIGE BEFESTIGUNGSFLANSCHE „SOCKET WELDING“ MIT VOLLDURCHGANG S.A.E. 3000 / ISO 6162-1 | |||||||||||||||

| REF. | PN bar1 | DN | ØA | ØB | L | GG | Q | FF | O | U | K | Schrauben | |||

| M | UNC | ||||||||||||||

| BFX-MONO-3000-SWI-1/2"-21.6 | 345 | 13 | 21.6 | 13 | 36 | 17.5 | 38.1 | 47 | 57 | 16 | 18 | M 8X30 | 5/16"-1"1/4 | ||

| BFX-MONO-3000-SWI-3/4"-27.2 | 19 | 27.2 | 19 | 36 | 22.3 | 47.6 | 49 | 66 | 18 | 18 | M 10X35 | 3/8"-1"1/2 | |||

| BFX-MONO-3000-SWI-1"-34 | 25 | 34.1 | 25 | 38 | 26.2 | 52.4 | 53 | 70 | 18 | 18 | M 10X35 | 3/8"-1"1/2 | |||

| BFX-MONO-3000-SWI-1"1/4-43 * | 278 | 32 | 42.8 | 31 | 41 | 30.2 | 58.7 | 69 | 80 | 21 | 20 | M 10X40 ou M 12X40* | 7/16"-1"1/2 | ||

| BFX-MONO-3000-SWI-1"1/2-49 * | 210 | 38 | 48.6 | 38 | 44 | 35.7 | 69.8 | 77 | 94 | 25 | 22 | M 12X45 ou M 14X45* | 1/2"-1"3/4 | ||

| BFX-MONO-3000-SWI-2"-61 * | 51 | 61 | 50 | 45 | 42.9 | 77.8 | 89 | 103 | 25 | 24 | M 12X45 ou M 14X45* | 1/2"-1"3/4 | |||

| BFX-MONO-3000-SWI-2"1/2-77 * | 175 | 64 | 76.6 | 63 | 50 | 50.8 | 88.9 | 101 | 115 | 25 | 28 | M 12X45 ou M 14X45* | 1/2"-1"3/4 | ||

| BFX-MONO-3000-SWI-3"-90.5 | 138 | 76 | 90.5 | 73 | 50 | 61.9 | 106.4 | 124 | 135 | 27 | 28 | M 16X50 | 5/8"-2" | ||

(1) Empfohlener Höchstdruck | |||||||||||||||

| BEINTEILIGE BEFESTIGUNGSFLANSCHE „SOCKET WELDING“ MIT VOLLDURCHGANG S.A.E. 6000 / ISO 6162-2 | |||||||||||||||

| REF. | PN bar1 | DN | ØA | ØB | L | GG | Q | FF | O | U | K | Schrauben | |||

| M | UNC | ||||||||||||||

| BFX-MONO-6000-SWI-1/2"-21.6 | 400 | 1/2" | 21.6 | 13 | 36 | 18.2 | 40.5 | 47 | 57 | 16 | 18 | M 8X30 | 5/16"-1"1/4 | ||

| BFX-MONO-6000-SWI-3/4"-27.2 | 3/4" | 27.2 | 19 | 36 | 23.8 | 50.8 | 53 | 71 | 19 | 20 | M 10X35 | 3/8"-1"1/2 | |||

| BFX-MONO-6000-SWI-1"-34 | 1" | 34.1 | 25 | 44 | 27.8 | 57.2 | 66 | 80 | 24 | 22 | M 12X45 | 7/16"-1"3/4 | |||

(1) Empfohlener Höchstdruck | |||||||||||||||

BEFESTIGUNGSFLANSCHE SOCKET WELDING MIT TEILDURCHGANG - SAE 3000 / SAE 6000

| BEFESTIGUNGSFLANSCHE „SOCKET WELDING“ MIT TEILDURCHGANG S.A.E. 3000 / ISO 6162-1 | ||||||||||||||||

| REF. | PN bar1 | DN | Außen-Ø Rohr | Ø L1 | Ø L2 | ØA | K | L | GG | Q | FF | O | Schrauben | |||

| MM | GAZ | SCHD | M | UNC | ||||||||||||

| BFX-3000-SWR-1/2"-16.3 BFX-3000-SWR-1/2"-17.6 | 315 | 13 | 16 | 16.75 | 17.14 | 16.3 17.6 | 24 | 12 | 13 | 35 | 17.5 | 38.1 | 46 | 54 | M 8X25 | 5/16-1"1/4 |

| BFX-3000-SWR-3/4"-18.5 BFX-3000-SWR-3/4"-20.5 BFX-3000-SWR-3/4"-21.7 | 19 | 18 20 | 21.25 | 21.34 | 18.5 20.5 21.7 | 31.5 | 13 | 13 | 40 | 22.3 | 47.6 | 52 | 65 | M 10X30 | 3/8-1"1/4 | |

| BFX-3000-SWR-1"-25.5 BFX-3000-SWR-1"-27.3 | 25 | 25 | 26.75 | 26.68 | 25.5 27.3 | 38 | 19 | 13 | 45 | 26.2 | 52.4 | 59 | 70 | M 10X30 | 3/8-1"1/4 | |

| BFX-3000-SWR-1"1/4-30.5 * BFX-3000-SWR-1"1/4-32.5 * BFX-3000-SWR-1"1/4-34 * BFX-3000-SWR-1"1/4-35.5 * | 200 | 32 | 30 32 35 | 33.50 | 33.40 | 30.5 32.5 34 35.5 | 43 | 25 | 16 | 50 | 30.2 | 58.7 | 73 | 79.5 | M 12X30* | 7/16-1"1/2 |

| BFX-3000-SWR-1"1/2-38.5 * BFX-3000-SWR-1"1/2-40.5 * BFX-3000-SWR-1"1/2-43 * | 38 | 38 40 42 | 42.25 | 42.16 | 38.5 40.5 42.8 | 50 | 32 | 18 | 55 | 35.7 | 69.8 | 83 | 94 | M 14X35* | 1/2-1"1/2 | |

| BFX-3000-SWR-2"-49 * BFX-3000-SWR-2"-50.7 * | 51 | 50 | 48.25 | 48.26 | 49 50.7 | 61.8 | 38 | 20 | 65 | 42.9 | 77.8 | 97 | 102 | M 14X35* | 1/2-1"1/2 | |

| BFX-3000-SWR-2"1/2-61 * BFX-3000-SWR-2"1/2-65.8 * | 150 | 64 | 60 65 | 60.30 | 60.30 | 61 65.8 | 73.8 | 47 | 22 | 75 | 50.8 | 88.9 | 109 | 114.5 | M 14X40* | 1/2-1"3/4 |

| BFX-3000-SWR-3"-74 BFX-3000-SWR-3"-77 BFX-3000-SWR-3"-81 | 100 | 76 | 80 | 76.10 | 73.02 | 74 77 81 | 90 | 58 | 25 | 85 | 61.9 | 106.4 | 131 | 135 | M 16X50 | 5/8-1"3/4 |

(1) Empfohlener Höchstdruck | ||||||||||||||||

| BEFESTIGUNGSFLANSCHE „SOCKET WELDING“ MIT TEILDURCHGANG S.A.E. 6000 / ISO 6162-2 | ||||||||||||||||

| REF. | PN bar1 | DN | Außen-Ø Rohr | Ø L1 | Ø L2 | ØA | K | L | GG | Q | FF | O | Schrauben | |||

| MM | GAZ | SCHD | M | UNC | ||||||||||||

| BFX-6000-SWR-1/2-16.3 BFX-6000-SWR-1/2-17.6 | 380 | 13 | 16 | 16.75 | 17.14 | 16.3 17.6 | 24 | 11 | 13 | 35 | 18.2 | 40.5 | 48 | 56.5 | M 8X30 | 5/16-1"1/4 |

| BFX-6000-SWR-3/4-18.5 BFX-6000-SWR-3/4-20.5 BFX-6000-SWR-3/4-21.7 | 19 | 18 20 | 21.25 | 21.34 | 18.5 20.5 21.7 | 32 | 13 | 13 | 40 | 23.8 | 50.8 | 60 | 71 | M 10X35 | 3/8-1"1/2 | |

| BFX-6000-SWR-1"-25.5 BFX-6000-SWR-1"-27.3 | 25 | 25 | 26.75 | 26.68 | 25.5 27.3 | 38 | 17 | 13 | 45 | 27.8 | 57.2 | 70 | 81 | M 12X45 | 7/16-1"3/4 | |

| BFX-6000-SWR-1"1/4-30.5* BFX-6000-SWR-1"1/4-32.5* BFX-6000-SWR-1"1/4-34* BFX-6000-SWR-1"1/4-35.5* | 300 | 32 | 30 32 35 | 33.50 | 33.40 | 30.5 32.5 34 35.5 | 44.5 | 22 | 16 | 50 | 31.8 | 66.6 | 78 | 95 | M 14X50* | 1/2-1"3/4 |

| BFX-6000-SWR-1"1/2-38.5 BFX-6000-SWR-1"1/2-40.5 BFX-6000-SWR-1"1/2-42.8 | 38 | 38 40 42 | 42.25 | 42.16 | 38.5 40.5 42.8 | 51 | 29 | 18 | 55 | 36.5 | 79.3 | 95 | 113 | M 16X55 | 5/8-2"1/4 | |

| BFX-6000-SWR-2"-49 BFX-6000-SWR-2"-50.8 | 51 | 50 | 48.25 | 48.26 | 49 50.8 | 67 | 35 | 20 | 65 | 44.5 | 96.8 | 114 | 133 | M 20X70 | 3/4-2"3/4 | |

(1) Empfohlener Höchstdruck | ||||||||||||||||

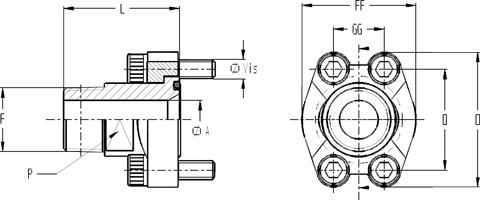

BEFESTIGUNGSFLANSCHE MIT GEWINDETÜLLEN FÜR GAS ODER NPT - SAE 3000 / SAE 6000

| BEFESTIGUNGSFLANSCHE MIT GEWINDETÜLLEN FÜR GAS ODER NPT S.A.E. 3000 / ISO 6162-1 | ||||||||||||||||

| REF. | PN Bar1 | DN | F Gaz oder NPT. | Ø A | L | GG | Q | FF | O | P | Schrauben | |||||

| M | UNC | |||||||||||||||

| BFX-3000-F-G-CO-1/2"-A BFX-3000-F-G-CO-1/2"-B | 300 | 13 | 1/2" 3/8" | 12 10 | 50 | 17.5 | 38.1 | 46 | 54 | 19 | M 8X25 | 5/16"-1"1/4 | ||||

| BFX-3000-F-G-CO-3/4"-A BFX-3000-F-G-CO-3/4"-B | 19 | 3/4" 1/2" | 17 12 | 55 | 22.3 | 47.6 | 52 | 65 | 27 | M10X30 | 3/8"-1"1/4 | |||||

| BFX-3000-F-G-CO-1"-A BFX-3000-F-G-CO-1"-B | 25 | 1" 3/4" | 22 17 | 60 | 26.2 | 52.4 | 59 | 70 | 32 | M10X30 | 3/8"-1"1/4 | |||||

| BFX-3000-F-G-CO-1"1/4-A * BFX-3000-F-G-CO-1"1/4-B * | 150 | 32 | 1"1/4 1" | 27 22 | 65 | 30.2 | 58.7 | 73 | 79.5 | 41 | M12X30 * | 7/16"-1"1/2 | ||||

| BFX-3000-F-G-CO-1"1/2-A * BFX-3000-F-G-CO-1"1/2-B * | 38 | 1"1/2 1"1/4 | 32 27 | 70 | 35.7 | 69.8 | 83 | 94 | 46 | M14X35 * | 1/2"-1"1/2 | |||||

| BFX-3000-F-G-CO-2"-A * BFX-3000-F-G-CO-2"-B * | 51 | 2" 1"1/2 | 40 30 | 75 | 42.9 | 77.8 | 97 | 102 | 55 | M14X35 * | 1/2"-1"1/2 | |||||

(1) Empfohlener Höchstdruck | ||||||||||||||||

| BEFESTIGUNGSFLANSCHE MIT GEWINDETÜLLEN FÜR GAS ODER NPT S.A.E. 6000 / ISO 6162-2 | ||||||||||||||||

| REF. | PN Bar1 | DN | F Gaz oder NPT. | Ø A | L | GG | Q | FF | O | P | Schrauben | |||||

| M | UNC | |||||||||||||||

| BFX-6000-F-G-CO-1/2"-A BFX-6000-F-G-CO-1/2"-B | 350 | 13 | 1/2" 3/8" | 12 10 | 50 50 | 18.2 | 40.5 | 48 | 56 | 19 | M 8X30 | 5/16"-1"1/4 | ||||

| BFX-6000-F-G-CO-3/4"-A BFX-6000-F-G-CO-3/4"-B | 19 | 3/4" 1/2" | 17 12 | 60 60 | 23.8 | 50.8 | 60 | 71 | 26 | M10X35 | 3/8"-1"1/2 | |||||

| BFX-6000-F-G-CO-1"-A BFX-6000-F-G-CO-1"-B | 25 | 1" 3/4" | 22 17 | 70 70 | 27.7 | 57.1 | 70 | 81 | 32 | M12X45 | 7/16"-1"3/4 | |||||

| BFX-6000-F-G-CO-1"1/4-A * BFX-6000-F-G-CO-1"1/4-B * | 250 | 32 | 1"1/4 1" | 27 22 | 75 75 | 31.7 | 66.7 | 78 | 95 | 36 | M14X50* | 1/2"-1"3/4 | ||||

| BFX-6000-F-G-CO-1"1/2-A BFX-6000-F-G-CO-1"1/2-B | 38 | 1"1/2 1"1/4 | 32 27 | 80 80 | 36.5 | 79.4 | 95 | 113 | 41 | M16X55 | 5/8"-2"1/4 | |||||

| BFX-6000-F-G-CO-2"-A BFX-6000-F-G-CO-2"-B | 200 | 51 | 2" 1"1/2 | 40 30 | 90 90 | 44.4 | 96.8 | 114 | 133 | 55 | M20X70 | 3/4"-2"3/4 | ||||

(1) Empfohlener Höchstdruck | ||||||||||||||||

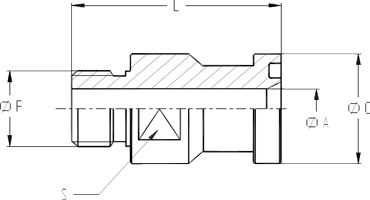

BEFESTIGUNGSFLANSCHE MIT UNF-AUSSENGEWINDE JIC - SAE 3000 / SAE 6000

| BEFESTIGUNGSFLANSCHE MIT UNF-AUSSENGEWINDE JIC S.A.E.3000 / ISO 6162-1 | |||||||||||

| REF. | PN Bar1 | DN | Ø F UNF-2A | Q | GG | FF2 | O2 | L | U | Schrauben | |

| M | UNC | ||||||||||

| BFX-3000-F-JIC-1/2"-A BFX-3000-F-JIC-1/2"-B BFX-3000-F-JIC-1/2"-C | 250 | 13 | 3/4"-16 7/8"-14 1"1/16-12 | 38.1 | 17.5 | 47 | 57 | 41 41 46 | 16 | M 8X30 | 5/16"-1"1/4 |

| BFX-3000-F-JIC-3/4"-A BFX-3000-F-JIC-3/4"-B BFX-3000-F-JIC-3/4"-C | 19 | 7/8"-14 1"1/16-12 1"5/16-12 | 47.6 | 22.3 | 49 | 66 | 47 49 50 | 18 | M 10X35 | 3/8"-1"1/2 | |

| BFX-3000-F-JIC-1"-A BFX-3000-F-JIC-1"-B BFX-3000-F-JIC-1"-C | 25 25 | 1"1/16-12 1"5/16-12 1"5/8-12 | 52.4 | 26.2 | 53 | 71 | 51 52 54 | 18 | M 10X35 | 3/8"-1"1/2 | |

| BFX-3000-F-JIC-1"1/4-A * BFX-3000-F-JIC-1"1/4-B * BFX-3000-F-JIC-1"1/4-C * | 32 | 1"5/16-12 1"5/8-12 1"7/8-12 | 58.7 | 30.2 | 69 | 80 | 56 58 61 | 21 | M 10X40 * ou M 12X40 | 7/16"-1"1/2 | |

| BFX-3000-F-JIC-1"1/2-A * BFX-3000-F-JIC-1"1/2-B * | 210 | 38 | 1"5/8-12 1"7/8-12 | 69.8 | 35.7 | 77 | 94 | 64 67 | 24 | M 12X45 *ou M 14X45 | 1/2"-1"3/4 |

(1) Empfohlener Höchstdruck | |||||||||||

| BEFESTIGUNGSFLANSCHE MIT UNF-AUSSENGEWINDE JIC S.A.E. 6000 / ISO 6262-2 | |||||||||||

| REF. | PN Bar1 | DN | Ø F UNF-2A | Q | GG | FF2 | O2 | L | U | Schrauben | |

| M | UNC | ||||||||||

| BFX-6000-F-JIC-1/2"-A BFX-6000-F-JIC-1/2"-B BFX-6000-F-JIC-1/2"-C | 350 | 13 | 3/4"-16 7/8"-14 1"1/16-12 | 40.5 | 18.3 | 47 | 57 | 42 45 47 | 16 | M 8X30 | 5/16"-1"1/4 |

| BFX-6000-F-JIC-3/4"-A BFX-6000-F-JIC-3/4"-B BFX-6000-F-JIC-3/4"-C | 19 | 7/8"-14 1"1/16-12 1"5/16-12 | 50.8 | 23.8 | 53 | 71 | 49 51 52 | 18 | M 10X35 | 3/8"-1"1/2 | |

| BFX-6000-F-JIC-1"-A BFX-6000-F-JIC-1"-B BFX-6000-F-JIC-1"-C | 25 | 1"1/16-12 1"5/16-12 1"5/8-12 | 57.1 | 27.8 | 69 | 80 | 58 59 61 | 21 | M 12X40 | 7/16"-1"3/4 | |

| 250 | |||||||||||

| BFX-6000-F-JIC-1"1/4-A * BFX-6000-F-JIC-1"1/4-B * BFX-6000-F-JIC-1"1/4-C * | 32 | 1"5/16-12 1"5/8-12 1"7/8-12 | 66.7 | 31.6 | 77 | 94 | 64 66 69 | 24 | M 14X45 * | 1/2"-1"3/4 | |

| BFX-6000-F-JIC-1"1/2-A BFX-6000-F-JIC-1"1/2-B | 38 | 1"5/8-12 1"7/8-12 | 79.4 | 36.7 | 89 | 106 | 70 73 | 27 | M 16X55 | 5/8"-2"1/4 | |

(1) Empfohlener Höchstdruck | |||||||||||

BEFESTIGUNGSFLANSCHE MIT BSPP- ODER NPT-GEWINDE - SAE 3000 / SAE 6000

| BEFESTIGUNGSFLANSCHE MIT BSPP- ODER NPT-GEWINDE S.A.E. 3000 / ISO 6162-1 | ||||||||||||||||||||||

| REF. | PN Bar1 | DN | Ø F | L | GG | Q | FF | ØA | K | U | O | Schrauben | ||||||||||

| BSPP | M | UNC | ||||||||||||||||||||

| BFX-3000-T-BSP-1/2" BFX-3000-T-BSP-1/2"-TAR-3/8" | 345 | 13 | 1/2" 3/8" | 36 | 17.5 | 38.1 | 47 | 13 | 15 13 | 16 | 57 | M 8X30 | 5/16'-1"1/4 | |||||||||

| BFX-3000-T-BSP-3/4" | 19 | 3/4" | 36 | 22.3 | 47.6 | 49 | 19 | 18 | 18 | 66 | M 10X35 | 3/8"-1"1/2 | ||||||||||

| BFX-3000-T-BSP-3/4"-TAR-1/2" | 1/2" | 13 | ||||||||||||||||||||

| BFX-3000-T-BSP-1" BFX-3000-T-BSP-1"-TAR-3/4" | 25 | 1" 3/4" | 38 | 26.2 | 52.4 | 53 | 25 19 | 20 | 18 | 71 | M 10X35 | 3/8"-1"1/2 | ||||||||||

| BFX-3000-T-BSP-1"1/4 * | 278 | 32 | 1"1/4 | 41 | 30.2 | 58.7 | 69 | 31 | 22 | 21 | 80 | M 10X40 ou | 7/16"-1"1/2 | |||||||||

| BFX-3000-T-BSP-1"1/4-TAR-1" * | 1" | 25 | M 12X40* | |||||||||||||||||||

| BFX-3000-T-BSP-1"1/2 * BFX-3000-T-BSP-1"1/2-TAR-1"1/4 * | 210 | 38 | 1"1/2 1"1/4 | 44 | 35.7 | 69.9 | 77 | 38 31 | 24 | 25 | 94 | M 12X45 ou M 14X45* | 1/2"-1"3/4 | |||||||||

| BFX-3000-T-BSP-2" * | 51 | 2" | 45 | 42.9 | 77.8 | 89 | 50 | 26 | 25 | 103 | M 12X45 ou | 1/2"-1"3/4 | ||||||||||

| BFX-3000-T-BSP-2"-TAR-1"1/2 * | 1"1/2 | 38 | M 14X45* | |||||||||||||||||||

| BFX-3000-T-BSP-2"1/2 * BFX-3000-T-BSP-2"1/2-TAR-2" * | 175 | 64 | 2"1/2 2" | 50 | 50.8 | 88.9 | 101 | 63 50 | 30 | 25 | 115 | M 12X45 ou M 14 X 45* | 1/2-1"3/4 | |||||||||

| BFX-3000-T-BSP-3" | 138 | 76 | 3" | 50 | 61.9 | 106.4 | 124 | 73 | 30 | 27 | 135 | M 16X50 | 5/8"-2" | |||||||||

| BFX-3000-T-BSP-3"-TAR-2"1/2 | 2"1/2 | 63 | ||||||||||||||||||||

| BFX-3000-T-BSP-3"1/2 | 35 | 89 | 3"1/2 | 50 | 69.8 | 120.7 | 136 | 89 | 30 | 27 | 152 | M 16X50 | 5/8"-2" | |||||||||

| BFX-3000-T-BSP-4" | 35 | 102 | 4" | 50 | 77.8 | 130.2 | 146 | 99 | 30 | 27 | 162 | M 16X50 | 5/8"-2" | |||||||||

(1) Empfohlener Höchstdruck | ||||||||||||||||||||||

| BEFESTIGUNGSFLANSCHE MIT BSPP- ODER NPT-GEWINDE S.A.E. 6000 / ISO 6162-2 | ||||||||||||||||||||||

| REF. | PN Bar1 | DN | Ø F | L | GG | Q | FF | ØA | K | U | O | Schrauben | ||||||||||

| BSP | M | UNC | ||||||||||||||||||||

| BFX-6000-T-BSP-1/2" BFX-6000-T-BSP-1/2"-TAR-3/8" | 400 | 13 | 1/2" 3/8 | 36 | 18.2 | 40.5 | 47 | 14 | 15 13 | 16 | 57 | M 8X30 | 5/16"-1"1/4 | |||||||||

| BFX-6000-T-BSP-3/4" | 19 | 3/4" | 36 | 23.8 | 50.8 | 53 | 19 | 18 | 19 | 71 | M 10X35 | 3/8"-1"1/2 | ||||||||||

| BFX-6000-T-BSP-3/4"-TAR-1/2" | 1/2" | 14 | ||||||||||||||||||||

| BFX-6000-T-BSP-1" BFX-6000-T-BSP-1"-TAR-3/4" | 25 | 1" 3/4" | 44 | 27.8 | 57.2 | 69 | 25 19 | 20 | 24 | 80 | M 12X45 | 7/16"-1"3/4 | ||||||||||

| BFX-6000-T-BSP-1"1/4 * | 32 | 1"1/4 | 44 | 31.6 | 66.6 | 77 | 31 | 22 | 27 | 94 | M 14X50* | 1/2"-1"3/4 | ||||||||||

| BFX-6000-T-BSP-1"1/4-TAR-1" * | 1" | 25 | ||||||||||||||||||||

| BFX-6000-T-BSP-1"1/2 BFX-6000-T-BSP-1"1/2-TAR-1"1/4 | 38 | 1"1/2 1"1/4 | 51 | 36.5 | 79.3 | 89 | 38 31 | 24 | 30 | 106 | M 16X55 | 5/8"-2"1/4 | ||||||||||

| BFX-6000-T-BSP-2" | 51 | 2" | 58 | 44.5 | 96.8 | 116 | 50 | 33 | 37 | 135 | M 20X70 | 3/4"-2"1/2 | ||||||||||

(1) Empfohlener Höchstdruck | ||||||||||||||||||||||

BEFESTIGUNGSFLANSCHE MIT UN-/UNF-GEWINDE - SAE 3000 / SAE 6000

| BEFESTIGUNGSFLANSCHE MIT UN-/UNF-GEWINDE S.A.E. 3000 / ISO 6162-1 | ||||||||||||||

| REF. | PN Bar1 | DN | Ø F UN / UNF | L | GG | Q | FF | ØA | K | U | O | Schrauben | ||

| M | UNC | |||||||||||||

| BFX-3000-T-UNF-1/2"--A | 345 | 13 | 3/4-16 | 36 | 17.5 | 38.1 | 47 | 13 | 17 | 16 | 57 | M 8X30 | 5/16'-1"1/4 | |

| BFX-3000-T-UNF-3/4"-A | 19 | 7/8"-14 | 36 | 22.3 | 47.6 | 49 | 19 | 17 | 18 | 66 | M 10X35 | 3/8"-1"1/2 | ||

| BFX-3000-T-UNF-3/4"-B | 1"1/16-12 | 23 | ||||||||||||

| BFX-3000-T-UNF-1"-A BFX-3000-T-UNF-1"-B | 25 | 1"1/16-12 1"5/16-12 | 38 | 26.2 | 52.4 | 53 | 25 | 23 | 18 | 71 | M 10X35 | 3/8"-1"1/2 | ||

| BFX-3000-T-UNF-1"1/4-A* | 278 | 32 | 1"5/16-12 | 41 | 30.2 | 58.7 | 69 | 31 | 23 | 21 | 80 | M 10X40 ou | 7/16"-1"1/2 | |

| BFX-3000-T-UNF-1"1/4-B* | 1"5/8-12 | M 12X40* | ||||||||||||

| BFX-3000-T-UNF-1"1/2-A* BFX-3000-T-UNF-1"1/2-B* | 210 | 38 | 1"5/8-12 1"7/8-12 | 44 | 35.7 | 69.8 | 77 | 38 | 23 | 25 | 94 | M 12X45 ou M 14X45* | 1/2"-1"3/4 | |

(1) Empfohlener Höchstdruck | ||||||||||||||

| BEFESTIGUNGSFLANSCHE MIT UN-/UNF-GEWINDE S.A.E. 6000 / ISO 6162-2 | ||||||||||||||

| REF. | PN Bar1 | DN | Ø F UN / UNF | L | GG | Q | FF | ØA | K | U | O | Schrauben | ||

| M | UNC | |||||||||||||

| BFX-6000-T-UNF-1/2-A | 400 | 13 | 3/4"-16 | 36 | 18.3 | 40.5 | 47 | 13 | 17 | 16 | 57 | M 8X30 | 5/16"-1"1/4 | |

| BFX-6000-T-UNF-3/4-A | 19 | 7/8"-14 | 36 | 23.8 | 50.8 | 53 | 19 | 17 | 19 | 71 | M 10X35 | 3/8"-1"1/2 | ||

| BFX-6000-T-UNF-3/4-B | 1"1/16-12 | 23 | ||||||||||||

| BFX-6000-T-UNF-1"-A BFX-6000-T-UNF-1"-B | 25 | 1"1/16-12 1"5/16-12 | 44 | 27.8 | 57.1 | 69 | 25 | 23 | 24 | 80 | M 12X45 | 7/16"-1"3/4 | ||

| BFX-6000-T-UNF-1"1/4-A* | 32 | 1"5/16-12 | 44 | 31.6 | 66.7 | 77 | 31 | 23 | 27 | 94 | M 14X50 * | 1/2"-1"3/4 | ||

| BFX-6000-T-UNF-1"1/4-B* | 1"5/8-12 | |||||||||||||

| BFX-6000-T-UNF-1"1/2-A BFX-6000-T-UNF-1"1/2-B | 38 | 1"5/8-12 1"7/8-12 | 51 | 36.7 | 79.4 | 89 | 38 | 23 | 30 | 106 | M 16X55 | 5/8"-2"1/4 | ||

(1) Empfohlener Höchstdruck | ||||||||||||||

BEFESTIGUNGSFLANSCHE MIT METRISCHEM ZYLINDRISCHEN

DIN-GEWINDE, ABDICHTUNG DURCH O-RING (ISO 6146-1 - SAE 3000 / SAE 6000

| BEFESTIGUNGSFLANSCHE MIT METRISCHEM ZYLINDRISCHEN DIN-GEWINDE, ABDICHTUNG DURCH O-RING (ISO 6146-1) S.A.E. 3000 / ISO 6162-1 | ||||||||||||||||

| REF. | PN Bar1 | DN | Ø F | L | GG | Q | FF | ØA | K | U | O | Schrauben | ||||

| DIN | M | UNC | ||||||||||||||

| BFX-3000-T-DIN-1/2"-A BFX-3000-T-DIN-1/2"-B | 345 | 13 | 18X1.5 20X1.5 | 36 | 17.5 | 38.1 | 47 | 13 | 15 | 16 | 57 | M 8X30 | 5/16'-1"1/4 | |||

| BFX-3000-T-DIN-3/4"-A | 19 | 22X1.5 | 36 | 22.3 | 47.6 | 49 | 19 | 16 | 18 | 66 | M 10X35 | 3/8"-1"1/2 | ||||

| BFX-3000-T-DIN-3/4"-B | 27X2 | 19 | ||||||||||||||

| BFX-3000-T-DIN-1"-A BFX-3000-T-DIN-1"-B | 25 | 27X2 33X2 | 38 | 26.2 | 52.4 | 53 | 25 | 19 | 18 | 71 | M 10X35 | 3/8"-1"1/2 | ||||

| BFX-3000-T-DIN-1"1/4-A* | 278 | 32 | 33X2 | 41 | 30.2 | 58.7 | 69 | 31 | 19 | 21 | 80 | M 10X40 ou | 7/16"-1"1/2 | |||

| BFX-3000-T-DIN-1"1/4-B* | 42X2 | 20 | M 12X40* | |||||||||||||

| BFX-3000-T-DIN-1"1/2-A* BFX-3000-T-DIN-1"1/2-B* | 210 | 38 | 42X2 48X2 | 44 | 35.7 | 69.8 | 77 | 38 | 20 22 | 25 | 94 | M 12X45 ou M 14X45* | 1/2"-1"3/4 | |||

(1) Empfohlener Höchstdruck | ||||||||||||||||

| BEFESTIGUNGSFLANSCHE MIT METRISCHEM ZYLINDRISCHEN DIN-GEWINDE, ABDICHTUNG DURCH O-RING (ISO 6146-1) S.A.E. 6000 / ISO 6162-2 | ||||||||||||||||

| REF. | PN Bar1 | DN | Ø F | L | GG | Q | FF | ØA | K | U | O | Schrauben | ||||

| DIN | M | UNC | ||||||||||||||

| BFX-6000-T-DIN-1/2-A BFX-6000-T-DIN-1/2-B | 400 | 13 | 18X1.5 20X1.5 | 36 | 18.2 | 40.5 | 47 | 13 | 15 | 16 | 57 | M 8X30 | 5/16"-1"1/4 | |||

| BFX-6000-T-DIN-3/4-A | 19 | 22X1.5 | 36 | 23.8 | 50.8 | 53 | 19 | 16 | 19 | 71 | M 10X35 | 3/8"-1"1/2 | ||||

| BFX-6000-T-DIN-3/4-B | 27X2 | 19 | ||||||||||||||

| BFX-6000-T-DIN-1"-A BFX-6000-T-DIN-1"-B | 25 | 27X2 33X2 | 44 | 27.8 | 57.2 | 69 | 25 | 19 | 24 | 80 | M 12X45 | 7/16"-1"3/4 | ||||

| BFX-6000-T-DIN-1"1/4-A* | 32 | 33X2 | 44 | 31.6 | 66.6 | 77 | 31 | 19 | 27 | 94 | M 14X50 * | 1/2"-1"3/4 | ||||

| BFX-6000-T-DIN-1"1/4-B* | 42X2 | 20 | ||||||||||||||

| BFX-6000-T-DIN-1"1/2-A BFX-6000-T-DIN-1"1/2-B | 38 | 42X2 48X2 | 51 | 36.5 | 79.3 | 89 | 38 | 20 22 | 30 | 106 | M 16X55 | 5/8"-2"1/4 | ||||

(1) Empfohlener Höchstdruck | ||||||||||||||||

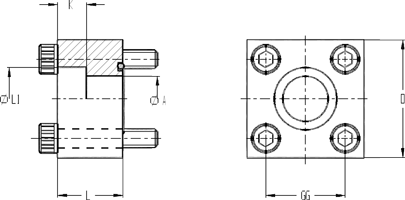

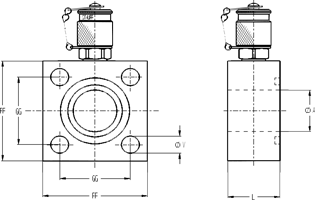

EINTEILIGE BEFESTIGUNGSFLANSCHE BWI - SAE 3000 / SAE 6000

| EINTEILIGE BEFESTIGUNGSFLANSCHE BWI S.A.E. 3000 / ISO 6162-1 | |||||||||||||

| REF. | PN bar1 | DN | ØA | ØB | L | GG | Q | FF | O | U | Schrauben | ||

| M | UNC | ||||||||||||

| BFX-MONO-3000-BWI-1/2" | 345 | 13 | 21.6 | 13 | 36 | 17.5 | 38.1 | 47 | 57 | 16 | M 8X30 | 5/16"-1"1/4 | |

| BFX-MONO-3000-BWI-3/4" | 19 | 27.2 | 19 | 36 | 22.3 | 47.6 | 49 | 66 | 18 | M 10X35 | 3/8"-1"1/2 | ||

| BFX-MONO-3000-BWI-1" | 315 | 25 | 34.5 | 25 | 38 | 26.2 | 52.4 | 53 | 71 | 18 | M 10X35 | 3/8"-1"1/2 | |

| BFX-MONO-3000-BWI-1"1/4 | 250 | 32 | 42.8 | 31 | 41 | 30.2 | 58.7 | 69 | 80 | 21 | M 10X40 ou M 12X40* | 7/16"-1"1/2 | |

| BFX-MONO-3000-BWI-1"1/2 | 210 | 38 | 48.6 | 38 | 44 | 35.7 | 69.8 | 77 | 94 | 25 | M 12X45 ou M 14X45* | 1/2"-1"3/4 | |

| BFX-MONO-3000-BWI-2" | 51 | 61 | 50 | 45 | 42.9 | 77.8 | 89 | 103 | 25 | M 12X45 ou M 14X45* | 1/2"-1"3/4 | ||

| BFX-MONO-3000-BWI-2"1/2 | 160 | 64 | 76.6 | 63 | 50 | 50.8 | 88.9 | 101 | 115 | 25 | M 12X45 ou M 14X45* | 1/2"-1"3/4 | |

| BFX-MONO-3000-BWI-3" | 138 | 76 | 89 | 73 | 50 | 61.9 | 106.4 | 124 | 135 | 27 | M 16X50 | 5/8"-2" | |

| BFX-MONO-3000-BWI-3"1/2 | 35 | 89 | 103 | 89 | 50 | 69.8 | 120.7 | 137 | 153 | 27 | M 16X50 | 5/8"-2" | |

| BFX-MONO-3000-BWI-4" | 102 | 115 | 99 | 50 | 77.8 | 130.2 | 147 | 163 | 27 | M 16X50 | 5/8"-2" | ||

| BFX-MONO-3000-BWI-5" | 127 | 141 | 120 | 50 | 92 | 152.4 | 180 | 184 | 28 | M 16X55 | 5/8"-2"1/4 | ||

(1) Empfohlener Höchstdruck | |||||||||||||

| EINTEILIGE BEFESTIGUNGSFLANSCHE BWI S.A.E. 6000 / ISO 6162-2 | |||||||||||||

| REF. | PN bar1 | DN | ØA | ØB | L | GG | Q | FF | O | U | Schrauben | ||

| M | UNC | ||||||||||||

| BFX-MONO-6000-BWR-1/2" | 400 | 13 | 17.5 | 10 | 36 | 18.2 | 40.5 | 47 | 57 | 18 | M 8X30 | 5/16"-1"1/4 | |

| BFX-MONO-6000-BWI-1/2" | 13 | 21.6 | 13 | 36 | 18.2 | 40.5 | 47 | 57 | 18 | M 8X30 | 5/16"-1"1/4 | ||

| BFX-MONO-6000-BWI-3/4" | 19 | 27.2 | 18 | 36 | 23.8 | 50.8 | 53 | 71 | 18 | M 10X35 | 3/8"-1"1/2 | ||

| BFX-MONO-6000-BWI-1" | 25 | 34.5 | 22 | 44 | 27.8 | 57.2 | 66 | 80 | 24 | M 12X45 | 7/16"-1"3/4 | ||

| BFX-MONO-6000-BWI-1"1/4 * | 32 | 42.8 | 28 | 44 | 31.8 | 66.6 | 77 | 94 | 25 | M 14X50 * | 1/2"-1"3/4 | ||

| BFX-MONO-6000-BWI-1"1/2 | 38 | 48.6 | 32 | 51 | 36.5 | 79.3 | 89 | 106 | 29 | M 16X55 | 5/8"-2"1/4 | ||

| BFX-MONO-6000-BWI-2" | 51 | 61 | 41 | 70 | 44.5 | 96.8 | 116 | 135 | 35 | M 20X70 | 3/4"-2"1/2 | ||

| BFX-MONO-6000-BWI-2"1/2 | 64 | 73.6 | 50 | 75 | 58.7 | 123.8 | 150 | 166 | 45 | M 24X90 | - | ||

| BFX-MONO-6000-BWI-3" | 76 | 90 | 58 | 90 | 71.4 | 152.4 | 178 | 208 | 55 | M 30X110 | - | ||

(1) Empfohlener Höchstdruck | |||||||||||||

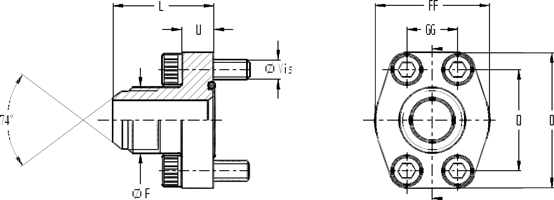

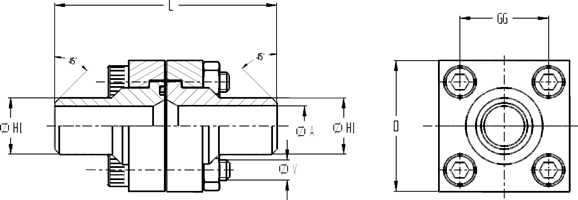

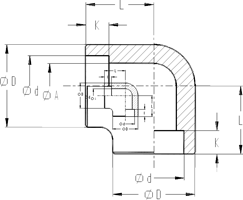

RECHTECKIGE BEFESTIGUNGSFLANSCHE BUTT WELDING MIT 90°-WINKEL - SAE 3000 / SAE 6000

| RECHTECKIGE BEFESTIGUNGSFLANSCHE „BUTT WELDING“ MIT 90°-WINKEL S.A.E. 3000 / ISO 6162-1 | ||||||||||||||

| REF. | PN Bar1 | DN | ØH1 | ØA | C | Q | O | GG | FF | M | N | L | Ø Schrauben | |

| M | UNC | |||||||||||||

| BFX-90°-3000-BWI-1/2" | 350 | 13 | 21.6 | 13 | 12 | 38.1 | 57 | 17.5 | 63 | 17 | 18 | 13 | M 8 | 5/16" |

| BFX-90°-3000-BWI-3/4" | 19 | 27.2 | 19 | 12 | 47.6 | 68 | 22.3 | 66 | 18 | 22 | 15 | M 10 | 3/8" | |

| BFX-90°-3000-BWI-1" | 315 | 25 | 34.5 | 25 | 13 | 52.4 | 74 | 26.2 | 77 | 19 | 28 | 15 | M 10 | 3/8" |

| BFX-90°-3000-BWI-1"1/4* | 250 | 32 | 42.8 | 31 | 13 | 58.7 | 81 | 30.2 | 91 | 22 | 30 | 17 | M 10 ou M 12* | 7/16" |

| BFX-90°-3000-BWI-1"1/2* | 210 | 38 | 48.6 | 38 | 14 | 69.8 | 95 | 35.7 | 105 | 25 | 36 | 18 | M 12 ou M14* | 1/2" |

| BFX-90°-3000-BWI-2"* | 51 | 61 | 50 | 15 | 77.8 | 105 | 42.9 | 110 | 25 | 41 | 18 | M 12 ou M 14* | 1/2" | |

Anmerkung: 2 1/2" auf Anfrage | ||||||||||||||

| RECHTECKIGE BEFESTIGUNGSFLANSCHE „BUTT WELDING“ MIT 90°-WINKEL S.A.E. 6000 / ISO 6162-2 | ||||||||||||||

| REF. | PN Bar1 | DN | ØH1 | ØA | C | Q | O | GG | FF | M | N | L | Ø Schrauben | |

| M | UNC | |||||||||||||

| BFX-90°-6000-BWI-1/2" | 400 | 13 | 21.6 | 13 | 12 | 40.5 | 57 | 18.2 | 63 | 17 | 18 | 13 | M 8 | 5/16" |

| BFX-90°-6000-BWI-3/4" | 19 | 27.2 | 18 | 12 | 50.8 | 72 | 23.8 | 77 | 20 | 28 | 15 | M 10 | 3/8" | |

| BFX-90°-6000-BWI-1" | 25 | 34.5 | 22 | 13 | 57.2 | 82 | 27.8 | 91 | 24 | 26 | 19 | M 12 | 7/16" | |

| BFX-90°-6000-BWI-1"1/4* | 32 | 42.8 | 28 | 13 | 66.6 | 95 | 31.8 | 105 | 25 | 36 | 21 | M 14* | 1/2" | |

| BFX-90°-6000-BWI-1"1/2 | 38 | 48.6 | 32 | 15 | 79.3 | 110 | 36.5 | 109 | 26 | 41 | 25 | M 16 | 5/8" | |

| BFX-90°-6000-BWI-2" | 51 | 61 | 41 | 15 | 96.8 | 134 | 44.5 | 133 | 35 | 45 | 32 | M 20 | 3/4" | |

Anmerkung: 2 1/2" auf Anfrage | ||||||||||||||

BEFESTIGUNGSFLANSCHE SOCKET WELDING MIT 90°-WINKEL - SAE 3000 / SAE 6000

| BEFESTIGUNGSFLANSCHE „SOCKET WELDING“ MIT 90°-WINKEL S.A.E. 3000 / ISO 6162-1 | |||||||||||||||||

| REF. | PN Bar1 | DN | ØL1 | ØA | ØL2 | K | Q | O | GG | FF | M | N | L | Ø Schrauben | |||

| M | UNC | ||||||||||||||||

| BFX-90°-3000-SWI-1/2"-21.6 | 315 | 13 | 21.6 | 13 | 34 | 5 | 38.1 | 57 | 17.5 | 51 | 17 | 18 | 13 | M 8 | 5/16" | ||

| BFX-90°-3000-SWI-3/4"-27.2 | 19 | 27.2 | 19 | 38.5 | 5 | 47.6 | 68 | 22.3 | 50 | 18 | 22 | 15 | M 10 | 3/8" | |||

| BFX-90°-3000-SWI-1"-34.5 | 25 | 34.1 | 25 | 44.5 | 6 | 52.4 | 72 | 26.2 | 55 | 19 | 28 | 15 | M 10 | 3/8" | |||

| BFX-90°-3000-SWI-1"1/4-42.8 | 200 | 32 | 42.8 | 31 | 53.5 | 7 | 58.7 | 82 | 30.2 | 68 | 22 | 30 | 17 | M 10 OU M 12* | 7/16" | ||

| BFX-90°-3000-SWI-1"1/2-49 | 38 | 48.6 | 38 | 62.5 | 8 | 69.8 | 95 | 35.7 | 82 | 25 | 36 | 18 | M 12 OU M 14* | 1/2" | |||

| BFX-90°-3000-SWI-2"-61 | 51 | 61 | 50 | 77 | 10 | 77.8 | 105 | 42.9 | 94 | 25 | 41 | 18 | M 12 OU M 14* | 1/2" | |||

Anmerkung: 2 1/2" auf Anfrage | |||||||||||||||||

| BEFESTIGUNGSFLANSCHE „SOCKET WELDING“ MIT 90°-WINKEL S.A.E. 6000 / ISO 6162-2 | |||||||||||||||||

| REF. | PN Bar1 | DN | ØL1 | ØA | ØL2 | K | Q | O | GG | FF | M | N | L | Ø Schrauben | |||

| M | UNC | ||||||||||||||||

| BFX-90°-6000-SWI-1/2"-21.6 | 400 | 13 | 21.6 | 13 | 34 | 5 | 40.5 | 57 | 18.2 | 51 | 17 | 18 | 13 | M 8 | 5/16" | ||

| BFX-90°-6000-SWI-3/4"-27.2 | 19 | 27.2 | 19 | 44.5 | 6 | 50.8 | 68 | 23.8 | 50 | 18 | 22 | 15 | M 10 | 3/8" | |||

| BFX-90°-6000-SWI-1"-34.1 | 25 | 34.1 | 25 | 53.5 | 7 | 57.2 | 72 | 27.8 | 55 | 19 | 28 | 15 | M 12 | 7/16" | |||

Anmerkung: 2 1/2" auf Anfrage | |||||||||||||||||

BEFESTIGUNGSFLANSCHE MIT GAS- ODER NPT-GEWINDE UND 90°-WINKEL - SAE 3000 / SAE 6000

| BEFESTIGUNGSFLANSCHE MIT GAS- ODER NPT-GEWINDE UND 90°-WINKEL S.A.E. 3000 / ISO 6162-1 | |||||||||||||||

| REF. | PN Bar1 | DN | ØF | ØA | M | N | L | Ø H | K | O | Q | FF | GG | Ø Schrauben | |

| M | UNC | ||||||||||||||

| BFX-90°-3000-T-BSP-1/2" | 345 | 13 | 1/2" | 13 | 17 | 18 | 13 | 34 | 19 | 57 | 38.1 | 59 | 17.5 | M 8 | 5/16" |

| BFX-90°-3000-T-BSP-3/4" | 19 | 3/4" | 19 | 18 | 22 | 15 | 38.5 | 19 | 68 | 47.6 | 63 | 22.3 | M 10 | 3/8" | |

| BFX-90°-3000-T-BSP-1" | 25 | 1" | 25 | 19 | 28 | 15 | 44.5 | 19 | 74 | 52.4 | 68 | 26.2 | M 10 | 3/8" | |

| BFX-90°-3000-T-BSP-1"1/4* | 278 | 32 | 1"1/4 | 31 | 22 | 30 | 17 | 53.5 | 22 | 81 | 58.7 | 84 | 30.2 | M 10 ou M 12* | 7/16" |

| BFX-90°-3000-T-BSP-1"1/2* | 210 | 38 | 1"1/2 | 38 | 25 | 36 | 18 | 62.5 | 24 | 95 | 69.8 | 97 | 35.7 | M 12 ou M 14* | 1/2" |

| BFX-90°-3000-T-BSP-2"* | 51 | 2" | 50 | 25 | 41 | 18 | 77 | 26 | 105 | 77.8 | 109 | 42.9 | M 12 ou M 14* | 1/2" | |

(1) Empfohlener Höchstdruck | |||||||||||||||

| BEFESTIGUNGSFLANSCHE MIT GAS- ODER NPT-GEWINDE UND 90°-WINKEL S.A.E. 6000 / ISO 6162-2 | |||||||||||||||

| REF. | PN Bar1 | DN | ØF | ØA | M | N | L | Ø H | K | O | Q | FF | GG | Ø Schrauben | |

| M | UNC | ||||||||||||||

| BFX-90°-6000-T-BSP-1/2" | 400 | 13 | 1/2" | 13 | 17 | 18 | 13 | 34 | 19 | 57 | 40.5 | 59 | 18.2 | M 8 | 5/16" |

| BFX-90°-6000-T-BSP-3/4" | 19 | 3/4" | 19 | 20 | 28 | 15 | 44.5 | 19 | 68 | 50.8 | 68 | 23.8 | M 10 | 3/8" | |

| BFX-90°-6000-T-BSP-1" | 25 | 1" | 25 | 24 | 30 | 19 | 53.5 | 19 | 74 | 57.2 | 84 | 27.8 | M 12 | 7/16" | |

| BFX-90°-6000-T-BSP-1"1/4* | 32 | 1"1/4 | 31 | 25 | 36 | 21 | 62.5 | 22 | 81 | 66.6 | 97 | 31.8 | M 14 * | 1/2" | |

| BFX-90°-6000-T-BSP-1"1/2 | 38 | 1"1/2 | 38 | 26 | 41 | 25 | 77 | 24 | 95 | 79.3 | 109 | 36.5 | M 16 | 5/8" | |

| BFX-90°-6000-T-BSP-2" | 51 | 2" | 50 | 35 | 45 | 32 | 87 | 26 | 105 | 96.8 | 133 | 44.4 | M 20 | 3/4" | |

(1) Empfohlener Höchstdruck | |||||||||||||||

BEFESTIGUNGSFLANSCHE MIT 90°-WINKEL UND METRISCHEM GEWINDE, MIT INNENKONUS 24°, DIN 2353 (ISO 8434-1) SAE 3000 / SAE 6000

| BEFESTIGUNGSFLANSCHE MIT 90°-WINKEL UND METRISCHEM GEWINDE, MIT INNENKONUS 24°, DIN 2353 (ISO 8434-1) S.A.E. 3000 / ISO 6162-1 | |||||||||||||

| REF. | PN bar1 | DN | Ø F | Ø D | Ø A | Q | GG | G | H | I | L | Ø Schrauben V(Nuss) | |

| M | UNC | ||||||||||||

| BFX-90°-3000-F-DIN-1/2"-A BFX-90°-3000-F-DIN-1/2"-B BFX-90°-3000-F-DIN-1/2"-C | 315 | 13 | 20X1.5 22X1.5 24X1.5 | 12 S 15 L 16 S | 8 11 12 | 38.1 | 17.5 | 36 | 16 | 18 | 14 | M 8 | 5/16" |

| 350 | |||||||||||||

| BFX-90°-3000-F-DIN-3/4"-A | 24X1.5 | 16 S | 12 | ||||||||||

| BFX-90°-3000-F-DIN-3/4"-B | 19 | 30X2.0 | 20 S | 16 | 47.6 | 22.3 | 38 | 18 | 22 | 14 | M 10 | 3/8" | |

| BFX-90°-3000-F-DIN-3/4"-C | 160 | 30X2.0 | 22 L | 18 | |||||||||

| BFX-90°-3000-F-DIN-1"-A BFX-90°-3000-F-DIN-1"-B BFX-90°-3000-F-DIN-1"-C | 315 | 25 | 30X2.0 36X2.0 36X2.0 | 20 S 25 S 28 L | 16 20 23 | 52.4 | 26.2 | 42 | 19 | 28 | 14 | M 10 | 3/8" |

| 160 | |||||||||||||

| BFX-90°-3000-F-DIN1"1/4-A* | 250 | 36X2.0 | 25 S | 20 | M10 | ||||||||

| BFX-90°-3000-F-DIN-1"1/4-B* | 32 | 42X2.0 | 30 S | 25 | 58.7 | 30.2 | 50 | 22 | 30 | 18 | ou | 7/16" | |

| BFX-90°-3000-F-DIN-1"1/4-C* | 160 | 45X2.0 | 35 L | 30 | M 12* | ||||||||

| BFX-90°-3000-F-DIN-1"1/2-A* BFX-90°-3000-F-DIN-1"1/2-B* BFX-90°-3000-F-DIN-1"1/2-C* | 38 | 45X2.0 52X2.0 52X2.0 | 35 L 38 S 42 L | 30 32 36 | 69.8 | 35.7 | 58 | 25 | 36 | 18 | M 12 ou M 14* | 1/2" | |

| 200 | |||||||||||||

| 160 | |||||||||||||

(1) Empfohlener Höchstdruck | |||||||||||||

| BEFESTIGUNGSFLANSCHE MIT 90°-WINKEL UND METRISCHEM GEWINDE, MIT INNENKONUS 24°, DIN 2353 (ISO 8434-1) S.A.E. 6000 / ISO 6162-2 | |||||||||||||

| REF. | PN bar1 | DN | Ø F | Ø D | Ø A | Q | GG | G | H | I | L | Ø Schrauben V(Nuss) | |

| M | UNC | ||||||||||||

| BFX-90°-6000-F-DIN-1/2"-A BFX-90°-6000-F-DIN-1/2"-B BFX-90°-6000-F-DIN-1/2"-C | 400 | 13 | 20X1.5 22X1.5 24X1.5 | 12 S 14 S 16 S | 8 10 12 | 40.5 | 18.2 | 36 | 16 | 20 | 14 | M 8 | 5/16" |

| BFX-90°-6000-F-DIN-3/4"-A | 24X1.5 | 16 S | 12 | ||||||||||

| BFX-90°-6000-F-DIN-3/4"-B | 19 | 30X2.0 | 20 S | 20 | 50.8 | 23.8 | 41 | 19 | 26 | 14 | M 10 | 3/8" | |

| BFX-90°-6000-F-DIN-3/4"-C | 160 | 30X2.0 | 22 L | 23 | |||||||||

| BFX-90°-6000-F-DIN-1"-A BFX-90°-6000-F-DIN-1"-B BFX-90°-6000-F-DIN-1"-C | 400 | 25 | 30X2.0 36X2.0 36X2.0 | 20 S 25 S 28 L | 16 20 23 | 57.2 | 27.8 | 50 | 24 | 30 | 14 | M 12 | 7/16" |

| 160 | |||||||||||||

| BFX-90°-6000-F-DIN-1"1/4-A* | 400 | 36X2.0 | 25 S | 20 | |||||||||

| BFX-90°-6000-F-DIN-1"1/4-B* | 32 | 42X2.0 | 30 S | 25 | 66.6 | 31.8 | 58 | 25 | 36 | 18 | M 14 * | 1/2" | |

| BFX-90°-6000-F-DIN-1"1/4-C* | 160 | 45X2.0 | 35 L | 30 | |||||||||

| BFX-90°-6000-F-DIN-1"1/2-A BFX-90°-6000-F-DIN-1"1/2-B BFX-90°-6000-F-DIN-1"1/2-C | 400 | 38 | 42X2.0 52X2.0 52X2.0 | 30 S 38 S 42 L | 25 32 36 | 79.3 | 36.5 | 65 | 26 | 41 | 18 | M 16 | 5/8" |

| 160 | |||||||||||||

(1) Empfohlener Höchstdruck | |||||||||||||

BEFESTIGUNGSFLANSCHE MIT BSP-AUSSENGEWINDE; MIT 90°-WINKEL - SAE 3000 / SAE 6000

| BEFESTIGUNGSFLANSCHE MIT BSP-AUSSENGEWINDE; MIT 90°-WINKEL S.A.E. 3000 / ISO 6162-1 | |||||||||||

| REF. | PN Bar1 | DN | Ø F BSPP | Q | GG | D | E | M | L | Ø Schrauben V(Nuss) | |

| M | UNC | ||||||||||

| BFX-90°-3000-F-MBSP-1/2"-A BFX-90°-3000-F-MBSP-1/2"-B BFX-90°-3000-F-MBSP-1/2"-C | 345 | 13 | 3/8" 1/2" 3/4" | 38.1 | 17.5 | 17 17 20 | 37 39 40 | 16 | 14 | M 8 | 5/16" |

| BFX-90°-3000-F-MBSP-3/4"-A | 1/2" | 20 | 41 | ||||||||

| BFX-90°-3000-F-MBSP-3/4"-B | 19 | 3/4" | 47.6 | 22.3 | 20 | 44 | 18 | 14 | M 10 | 3/8" | |

| BFX-90°-3000-F-MBSP-3/4"-C | 1" | 25 | 45 | ||||||||

| BFX-90°-3000-F-MBSP-1"-A BFX-90°-3000-F-MBSP-1"-B BFX-90°-3000-F-MBSP-1"-C | 25 | 3/4" 1" 1"1/4 | 52.4 | 26.2 | 20 25 31 | 47 48 49 | 19 | 14 | M 10 | 3/8" | |

| BFX-90°-3000-F-MBSP-1"1/4-A* | 278 | 1" | 25 | 54 | M 10 | ||||||

| BFX-90°-3000-F-MBSP-1"1/4-B* | 32 | 1"1/4 | 58.7 | 30.2 | 31 | 55 | 22 | 18 | ou | 7/16" | |

| BFX-90°-3000-F-MBSP-1"1/4-C* | 1"1/2 | 37 | 56 | M 12* | |||||||

| BFX-90°-3000-F-MBSP-1"1/2-A* BFX-90°-3000-F-MBSP-1"1/2-B* | 210 | 38 | 1"1/4 1"1/2 | 69.8 | 35.7 | 31 37 | 59 61 | 25 | 18 | M 12 ou M 14* | 1/2" |

(1) Empfohlener Höchstdruck | |||||||||||

| BEFESTIGUNGSFLANSCHE MIT BSP-AUSSENGEWINDE; MIT 90°-WINKEL S.A.E. 6000 / ISO 6162-2 | |||||||||||

| REF. | PN bar1 | DN | Ø F BSPP | Q | GG | D | E | M | L | Ø Schrauben V(Nuss) | |

| M | UNC | ||||||||||

| BFX-90°-6000-F-MBSP-1/2"-A BFX-90°-6000-F-MBSP-1/2"-B BFX-90°-6000-F-MBSP-1/2"-C | 400 | 13 | 3/8" 1/2" 3/4" | 40.5 | 18.2 | 17 17 20 | 37 39 40 | 16 | 14 | M 8 | 5/16" |

| BFX-90°-6000-F-MBSP-3/4"-A | 1/2" | 20 | 45 | ||||||||

| BFX-90°-6000-F-MBSP-3/4"-B | 19 | 3/4" | 50.8 | 23.8 | 20 | 48 | 19 | 14 | M 10 | 3/8" | |

| BFX-90°-6000-F-MBSP-3/4"-C | 1" | 25 | 50 | ||||||||

| BFX-90°-6000-F-MBSP-1"-A BFX-90°-6000-F-MBSP-1"-B BFX-90°-6000-F-MBSP-1"-C | 25 | 3/4" 1" 1"1/4 | 57.2 | 27.8 | 25 25 31 | 52 54 55 | 24 | 18 | M 12 | 7/16" | |

| BFX-90°-6000-F-MBSP-1"1/4-A* | 1" | 31 | 59 | ||||||||

| BFX-90°-6000-F-MBSP-1"1/4-B* | 32 | 1"1/4 | 66.6 | 31.8 | 31 | 59 | 25 | 18 | M 14* | 1/2" | |

| BFX-90°-6000-F-MBSP-1"1/4-C* | 1"1/2 | 37 | 61 | ||||||||

| BFX-90°-6000-F-MBSP-1"1/2-A BFX-90°-6000-F-MBSP-1"1/2-B | 38 | 1"1/4 1"1/2 | 79.3 | 36.5 | 37 37 | 64 66 | 26 | 20 | M 16 | 5/8" | |

(1) Empfohlener Höchstdruck | |||||||||||

BEFESTIGUNGSFLANSCHE MIT JIC-AUSSENGEWINDE; MIT 90°-WINKEL - SAE 3000 / SAE 6000

| BEFESTIGUNGSFLANSCHE MIT JIC-AUSSENGEWINDE; MIT 90°-WINKEL S.A.E. 3000 / ISO 6162-1 | |||||||||||

| REF. | PN bar1 | DN | Ø F | Q | GG | D | E | H | L | Ø Schrauben | |

| M | UNC | ||||||||||

| BFX-90°-3000-F-JIC-1/2"-A BFX-90°-3000-F-JIC-1/2"-B BFX-90°-3000-F-JIC-1/2"-C | 250 | 13 | 3/4"-16 7/8"-14 1"1/16-12 | 38,1 | 17.5 | 17 17 20 | 40 42 43 | 16 | 14 | M 8 | 5/16" |

| BFX-90°-3000-F-JIC-3/4"-A BFX-90°-3000-F-JIC-3/4"-B BFX-90°-3000-F-JIC-3/4"-C | 19 | 7/8"-14 1"1/16-12 1"5/16-12 | 47.6 | 22.3 | 20 20 25 | 45 47 48 | 18 | 14 | M 10 | 3/8" | |

| BFX-90°-3000-F-JIC-1"-A BFX-90°-3000-F-JIC-1"-B | 25 | 1"1/16-12 1"5/16-12 | 52.4 | 26.2 | 20 25 | 50 51 | 19 | 15 | M 10 | 3/8" | |

| BFX-90°-3000-F-JIC-1"1/4-A* BFX-90°-3000-F-JIC-1"1/4-B* BFX-90°-3000-F-JIC-1"1/4-C* | 32 | 1"5/16-12 1"5/8-12 1"7/8-12 | 58.7 | 30.2 | 25 31 37 | 56 58 61 | 22 | 18 | M 10 ou M 12* | 7/16" | |

| BFX-90°-3000-F-JIC-1"1/2-A* BFX-90°-3000-F-JIC-1"1/2-B* | 210 | 38 | 1"5/8-12 1"7/8-12 | 69.8 | 35.7 | 31 37 | 63 66 | 25 | 20 | M 12 ou M 14* | 1/2" |

(1) Empfohlener Höchstdruck | |||||||||||

| BEFESTIGUNGSFLANSCHE MIT JIC-AUSSENGEWINDE; MIT 90°-WINKEL S.A.E. 6000 –/ ISO 6162-2 | |||||||||||

| REF. | PN bar1 | DN | Ø F | Q | GG | D | E | H | L | Ø Schrauben | |

| M | UNC | ||||||||||

| BFX-90°-6000-F-JIC-1/2"-A BFX-90°-6000-F-JIC-1/2"-B BFX-90°-6000-F-JIC-1/2"-C | 350 | 13 | 3/4"-16 7/8"-14 1"1/16-12 | 40.5 | 18.2 | 17 17 20 | 40 42 43 | 16 | 14 | M 8 | 5/16" |

| BFX-90°-6000-F-JIC-3/4"-A BFX-90°-6000-F-JIC-3/4"-B BFX-90°-6000-F-JIC-3/4"-C | 19 | 7/8"-14 1"1/16-12 1"5/16-12 | 50.8 | 23.8 | 20 20 25 | 49 51 52 | 19 | 14 | M 10 | 3/8" | |

| BFX-90°-6000-F-JIC-1"-A BFX-90°-6000-F-JIC-1"-B BFX-90°-6000-F-JIC-1"-C | 25 | 1"1/16-12 1"5/16-12 1"5/8-12 | 57.2 | 27.8 | 25 25 31 | 55 56 58 | 24 | 18 | M 12 | 7/16" | |

| 250 | |||||||||||

| BFX-90°-6000-F-JIC-1"1/4-A* BFX-90°-6000-F-JIC-1"1/4-B* BFX-90°-6000-F-JIC-1"1/4-C* | 32 | 1"5/16-12 1"5/8-12 1"7/8-12 | 66.6 | 31.8 | 31 31 37 | 56 63 63 | 25 | 18 | M 14 * | 1/2" | |

| BFX-90°-6000-F-JIC-1"1/2-A BFX-90°-6000-F-JIC-1"1/2-B | 38 | 1"5/8-12 1"7/8-12 | 79.3 | 36.5 | 37 37 | 67 70 | 26 | 20 | M 16 | 5/8" | |

(1) Empfohlener Höchstdruck | |||||||||||

Druckentnahmeflansche

| DRUCKENTNAHMEFLANSCHE S.A.E. 3000 – ISO 6162-1 | |||||||||

| REF. | PN bar1 | DN | Ø A | L | GG | Q | FF | O | Ø V |

| BM-3000-PRISE-TEST-XX-3/8"-M BM-3000-PRISE-TEST-XX-1/2"-M/U | 350 | 10 13 | 12 13 | 22 25 | 16.5 17.5 | 35 38.1 | 40 45 | 50 54 | 9 9 |

| BM-3000-PRISE-TEST-XX-3/4"-M/U | 19 | 19 | 30 | 22.3 | 47.6 | 50 | 65 | 11 | |

| BM-3000-PRISE-TEST-XX-1"-M/U BM-3000-PRISE-TEST-XX-1"1/4 M ISO ou M/U* | 315 | 25 32 | 25 32 | 30 35 | 26.2 30.2 | 52.4 58.7 | 60 75 | 70 80 | 11 11 oder 13 |

| 250 | |||||||||

| BM-3000-PRISE-TEST-XX-1"1/2 M ou U/ISO* | 210 | 38 | 38 | 35 | 35.7 | 69.8 | 80 | 94 | 13.5 oder 15 |

| BM-3000-PRISE-TEST-XX-2" M ou U/ISO* BM-3000-PRISE-TEST-XX-2"1/2 M ou U/ISO* | 51 64 | 47 58 | 40 40 | 42.9 50.8 | 77.8 88.9 | 100 110 | 102 114 | 13.5 oder 15 13.5 oder 15 | |

| 160 | |||||||||

| BM-3000-PRISE-TEST-XX-3" M/U | 138 | 76 | 70 | 45 | 61.9 | 106.4 | 130 | 135 | 17 |

(1) Empfohlener Höchstdruck | |||||||||

| DRUCKENTNAHMEFLANSCHE S.A.E. 6000 – ISO 6162-2 | |||||||||

| REF. | PN bar1 | DN | Ø A | L | GG | Q | FF | O | Ø V |

| BM-6000-PRISE-TEST-XX-1/2-M/U BM-6000-PRISE-TEST-XX-3/4"-M/U | 400 | 13 19 | 13 17.5 | 25 30 | 18.2 23.8 | 40.5 50.8 | 48 60 | 56 71 | 9 11 |

| BM-6000-PRISE-TEST-XX-1"-M/U | 25 | 22 | 30 | 27.8 | 57.2 | 70 | 81 | 12.5 | |

| BM-6000-PRISE-TEST-XX-1"1/4-M ou U/ISO* BM-6000-PRISE-TEST-XX-1"1/2-M/U | 32 38 | 29 35 | 35 35 | 31.8 36.5 | 66.6 79.3 | 78 95 | 95 113 | 13.5 oder 15 17 | |

| BM-6000-PRISE-TEST-XX-2" M/ U/ISO | 51 | 43 | 40 | 44.5 | 96.8 | 114 | 133 | 21 | |

(1) Empfohlener Höchstdruck | |||||||||

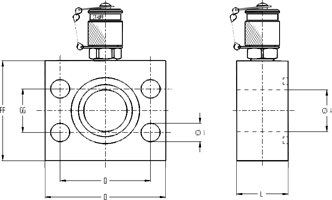

Anschlussflansch

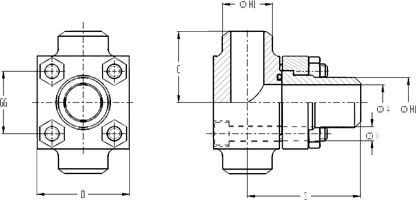

ANSCHLUSSFLANSCHE BUTT WELDING MIT VOLLDURCHGANG - SAE 3000 / SAE 6000

| ANSCHLUSSFLANSCHE „BUTT WELDING“ MIT VOLLDURCHGANG S.A.E. 3000 – ISO 6162-1 | |||||||||||

| REF. | PN bar1 | DN | Außen-Ø Rohr von... bis | Ø A | Ø H1 | L | FF | O | GG | Q | Schrauben M |

| BL-3000-BWI-3/8" ** BL-3000-BWI-1/2" | 350 | 10 13 | 14 -18 18 -22 | 12 13 | 18 22 | 80 90 | 40 46 | 50 54 | 16.5 17.5 | 35 38.1 | M 8X45 M 8X40 |

| BL-3000-BWI-3/4" | 19 | 25 - 28 | 19 | 28 | 100 | 52 | 65 | 22.3 | 47.6 | M 10X40 | |

| BL-3000-BWI-1" BL-3000-BWI-1"1/4 * | 315 | 25 32 | 30 - 35 38 - 43 | 25 32 | 35 43 | 110 120 | 59 73 | 70 79.5 | 26.2 30.2 | 52.4 58.7 | M 10X45 M 12X45* |

| 250 | |||||||||||

| BL-3000-BWI-1"1/2 * | 210 | 38 | 48 - 50 | 38 | 50 | 130 | 83 | 94 | 35.7 | 69.8 | M 14X50 * |

| BL-3000-BWI-2" * BL-3000-BWI-2"1/2 * | 51 64 | 60 - 63 73 - 76 | 47 58 | 61.8 74 | 140 150 | 97 109 | 102 114.5 | 42.9 50.8 | 77.8 88.9 | M 14X50 * M 14X55 * | |

| 160 | |||||||||||

| BL-3000-BWI-3" | 138 | 76 | 88 - 90 | 70 | 90 | 170 | 131 | 135 | 61.9 | 106.4 | M 16X65 |

| BL-3000-BWI-3"1/2 BL-3000-BWI-4" | 35 | 89 102 | 95 - 102 113 - 120 | 86 96 | 102 114 | 180 200 | 140 152 | 152 162 | 69.8 77.8 | 120.7 130.2 | M 16X65 M 16X70 |

(1) Empfohlener Höchstdruck | |||||||||||

| ANSCHLUSSFLANSCHE „BUTT WELDING“ MIT VOLLDURCHGANG S.A.E. 6000 – ISO 6162-2 | |||||||||||

| REF. | PN bar1 | DN | Außen-Ø Rohr von... bis | Ø A | Ø H1 | L | FF | O | GG | Q | Schrauben M |

| BL-6000-BWI-1/2" BL-6000-BWI-3/4" | 400 | 13 19 | 20 - 22 25 - 28 | 13 17.5 | 22 28 | 90 100 | 48 60 | 56.5 71 | 18.2 23.8 | 40.5 50.8 | M 8X45 M 10X50 |

| BL-6000-BWI-1" | 25 | 30 - 35 | 22 | 35 | 110 | 70 | 81 | 27.8 | 57.2 | M 12X65 | |

| BL-6000-BWI-1"1/4 * BL-6000-BWI-1"1/2 | 32 38 | 38 - 43 48 - 52 | 29 35 | 43.8 50.6 | 120 130 | 78 95 | 95 113 | 31.8 36.5 | 66.6 79.3 | M 14X70 * M 16X80 | |

| BL-6000-BWI-2" | 51 | 60 - 65 | 43 | 65 | 140 | 114 | 133 | 44.5 | 96.8 | M 20X100 | |

(1) Empfohlener Höchstdruck | |||||||||||

ANSCHLUSSFLANSCHE BUTT WELDING MIT TEILDURCHGANG - SAE 3000 / SAE 6000

| ANSCHLUSSFLANSCHE „BUTT WELDING“ MIT TEILDURCHGANG S.A.E. 3000 – ISO 6162-1 | |||||||||||

| REF. | PN bar1 | DN | Außen-Ø Rohr von... bis | ØA | ØH1 | L | FF | O | GG | Q | Schrauben M |

| BL-3000-BWR-1/2" BL-3000-BWR-3/4" | 350 | 13 19 | 14 - 18 18 - 22 | 12 13 | 18 22 | 90 100 | 46 52 | 54 65 | 17.5 22.3 | 38.1 47.6 | M 8X40 M 10X40 |

| BL-3000-BWR-1" | 315 | 25 | 25 - 28 | 19 | 28 | 110 | 59 | 70 | 26.2 | 52.4 | M 10X45 |

| BL-3000-BWR-1"1/4 * BL-3000-BWR-1"1/2 * | 250 | 32 38 | 30 - 35 38 - 43 | 25 32 | 35 43 | 120 130 | 73 83 | 79.5 94 | 30.2 35.7 | 58.7 69.8 | M 12X45 * M 14X50 * |

| 210 | |||||||||||

| BL-3000-BWR-2" * | 51 | 48 - 50 | 38 | 50 | 140 | 97 | 102 | 42.9 | 77.8 | M 14X50 * | |

| BL-3000-BWR-2"1/ 2 * BL-3000-BWR-3" | 160 | 64 76 | 60 - 63 73 - 76 | 47 58 | 61.8 76 | 150 170 | 109 131 | 114.5 135 | 50.8 61.9 | 88.9 106.4 | M 14X55 * M 16X65 |

| 138 | |||||||||||

| BL-3000-BWR-3"1/2 | 35 | 89 | 88 - 90 | 70 | 90 | 180 | 140 | 152 | 69.8 | 120.7 | M 16X65 |

| BL-3000-BWR-4" | 102 | 95 - 102 | 80 | 102 | 200 | 152 | 162 | 77.8 | 130.2 | M 16X70 | |

(1) Empfohlener Höchstdruck | |||||||||||

| ANSCHLUSSFLANSCHE „BUTT WELDING“ MIT TEILDURCHGANG S.A.E. 6000 – ISO 6162-2 | |||||||||||

| REF. | PN bar1 | DN | Außen-Ø Rohr von... bis | ØA | ØH1 | L | FF | O | GG | Q | Schrauben M |

| BL-6000-BWR-1/2" BL-6000-BWR-3/4" | 400 | 13 19 | 16 - 18 20 - 22 | 11 13 | 17.5 22 | 90 100 | 48 60 | 56.5 71 | 18.2 23.8 | 40.5 50.8 | M 8X45 M 10X50 |

| BL-6000-BWR-1" | 25 | 25 - 28 | 17.5 | 28 | 110 | 70 | 81 | 27.8 | 57.2 | M 12X65 | |

| BL-6000-BWR-1"1/4 * BL-6000-BWR-1"1/2 | 32 38 | 30 - 35 38 -43 | 22 29 | 35 43.8 | 120 130 | 78 95 | 95 113 | 31.8 36.5 | 66.6 79.3 | M 14X70 * M 16X80 | |

| BL-6000-BWR-2" | 51 | 48 - 52 | 35 | 51 | 140 | 114 | 133 | 44.5 | 96.8 | M 20X100 | |

(1) Empfohlener Höchstdruck | |||||||||||

ANSCHLUSSFLANSCHE SOCKET WELDING MIT TEILDURCHGANG - SAE 3000 / SAE 6000

| ANSCHLUSSFLANSCHE „ SOCKET“ WELDING MIT TEILDURCHGANG S.A.E. 3000 – ISO 6162-1 | |||||||||||||||

| REF. | PN Bar1 | DN | Außen-Ø Rohr | ØL1 | ØL2 | ØA | K | L | GG | Q | FF | O | Schrauben | ||

| MM | GAZ | SCHD | |||||||||||||

| BL-3000-SWR-1/2"-16.5 BL-3000-SWR-1/2"-17.6 | 315 | 13 | 16 | 16,75 | 17.14 | 16.5 17.6 | 24 | 12 | 12 | 70 | 17.5 | 38.1 | 46 | 54 | M 8X40 |

| BL-3000-SWR-3/4"-18.5 BL-3000-SWR-3/4"-20.5 BL-3000-SWR-3/4"-21.7 | 19 | 18 20 | 21.25 | 21.34 | 18.5 20.5 21.7 | 31.5 | 13 | 13 | 80 | 22.3 | 47.6 | 52 | 65 | M 10X40 | |

| BL-3000-SWR-1"-25.5 BL-3000-SWR-1"-27.3 | 25 | 25 | 26.75 | 26.68 | 25.5 27.3 | 38 | 19 | 14 | 90 | 26.2 | 52.4 | 59 | 70 | M 10X45 | |

| BL-3000-SWR-1"1/4-30.5* BL-3000-SWR-1"1/4-32.5* BL-3000-SWR-1"1/4-34* BL-3000-SWR-1"1/4-35.5* | 200 | 32 | 30 32 35 | 33.50 | 33.50 | 30.5 32.5 34 35.5 | 43 | 25 | 16 | 100 | 30.2 | 58.7 | 73 | 79.5 | M 12X45* |

| BL-3000-SWR-1"1/2-38.5* BL-3000-SWR-1"1/2-40.7* BL-3000-SWR-1"1/2-43* | 38 | 38 40 42 | 42.25 | 42.16 | 38.5 40.7 43 | 50 | 32 | 18 | 110 | 35.7 | 69.8 | 83 | 94 | M 14X50* | |

| BL-3000-SWR-2"-49* BL-3000-SWR-2"-50.7* | 51 | 50 | 48.25 | 48.26 | 49 50.7 | 61.8 | 38 | 20 | 130 | 42.9 | 77.8 | 97 | 102 | M 14X50* | |

| BL-3000-SWR-2"1/2-61* BL-3000-SWR-2"1/2-65.8* | 150 | 64 | 60 65 | 60.30 | 60.30 | 61 65.8 | 73.8 | 47 | 22 | 150 | 50.8 | 88.9 | 109 | 114.5 | M 14X55* |

| BL-3000-SWR-3"-74 BL-3000-SWR-3"-77 | 100 | 76 | 76.10 | 73.02 | 74 77 | 90 | 58 | 24 | 170 | 61.9 | 106.4 | 131 | 135 | M 16X65 | |

| BL-3000-SWR-3"-81 | 80 | 81 | |||||||||||||

(1) Empfohlener Höchstdruck | |||||||||||||||

| ANSCHLUSSFLANSCHE „ SOCKET“ WELDING MIT TEILDURCHGANG S.A.E. 6000 – ISO 6162-2 | |||||||||||||||

| REF. | PN Bar1 | DN | Außen-Ø Rohr | ØL1 | ØL2 | ØA | K | L | GG | Q | FF | O | Schrauben | ||

| MM | GAZ | SCHD | |||||||||||||

| BL-6000-SWR-1/2"-16.5 BL-6000-SWR-1/2"-17.6 | 380 | 13 | 16 | 16,75 | 17.14 | 16.5 17.6 | 24 | 11 | 13 | 70 | 18.2 | 40.5 | 48 | 56.5 | M 8X45 |

| BL-6000-SWR-3/4"-18.5 BL-6000-SWR-3/4"-20.5 BL-6000-SWR-3/4"-21.7 | 19 | 18 20 | 21.25 | 21.34 | 18.5 20.5 21.7 | 31.8 | 13 | 13 | 80 | 23.8 | 50.8 | 60 | 71 | M 10X50 | |

| BL-6000-SWR-1"-25.5 BL-6000-SWR-1"-27.3 | 25 | 25 | 26.75 | 26.68 | 25.5 27.3 | 38 | 17.5 | 13 | 90 | 27.8 | 57.2 | 70 | 81 | M 12X65 | |

| BL-6000-SWR-1"1/4-30.5* BL-6000-SWR-1"1/4-32.5* BL-6000-SWR-1"1/4-34* | 300 | 32 | 30 32 | 33.50 | 33.40 | 30.5 32.5 34 | 44 | 22 | 16 | 100 | 31.8 | 66.6 | 78 | 95 | M 14X70 |

| BL-6000-SWR-1"1/4-35.5* | 35 | 35.5 | |||||||||||||

| BL-6000-SWR-1"1/2-38.5 | 38 | 38.5 | |||||||||||||

| BL-6000-SWR-1"1/2-40.5 BL-6000-SWR-1"1/2-42.8 | 38 | 40 42 | 42.25 | 42.16 | 40.5 42.8 | 51 | 29 | 18 | 110 | 36.5 | 79.3 | 95 | 113 | M 16X80 | |

| BL-6000-SWR-2"-49 BL-6000-SWR-2"-50.8 | 51 | 50 | 48.25 | 48.26 | 49 50.8 | 67 | 35 | 20 | 130 | 44.5 | 96.8 | 114 | 133 | M 20X100 | |

(1) Empfohlener Höchstdruck | |||||||||||||||

ANSCHLUSSFLANSCHE SOCKET WELDING MIT VOLLDURCHGANG - SAE 3000 / SAE 6000

| ANSCHLUSSFLANSCHE „ SOCKET WELDING“ MIT VOLLDURCHGANG - SAE 3000 / ISO 6162-1 | ||||||||||||||||||

| REF. | PN Bar1 | DN | Außen-Ø Rohr | Ø L1 | Ø L2 | Ø A | K | L | Schrauben M | |||||||||

| MM | GAZ | SCHD | ||||||||||||||||

| BL-3000-SWI-1/2"-20.5 BL-3000-SWI-1/2"-21.7 | 315 | 13 | 20 | 21.15 | 21.34 | 20.5 21.7 | 30 | 13 | 13 | 80 | M 8X25 | |||||||

| BL-3000-SWI-3/4"-25.5 | 19 | 25 | 25.5 | 35 | 19 | 13 | 88 | M 10X30 | ||||||||||

| BL-3000-SWI-3/4"-27.3 | 26.75 | 26.68 | 27.3 | |||||||||||||||

| BL-3000-SWI-1"-30.5 BL-3000-SWI-1"-32.5 BL-3000-SWI-1"-34 BL-3000-SWI-1"-35.5 | 25 | 30 32 35 | 33.50 | 33.40 | 30.5 32.5 34 35.5 | 44 | 25 | 16 | 100 | M 10X30 * | ||||||||

| BL-3000-SWI-1"1/4-38.5 * BL-3000-SWI-1"1/4-40.5 * | 200 | 32 | 38 40 | 38.5 40.5 | 55 | 32 | 18 | 120 | M 12X30 * | |||||||||

| BL-3000-SWI-1"1/4-43 * | 42 | 42.25 | 42.16 | 43 | ||||||||||||||

| BL-3000-SWI-1"1/2-49 * BL-3000-SWI-1"1/2-50.4 * | 38 | 50 | 48.25 | 48.26 | 49 50.4 | 63 | 38 | 20 | 130 | M 14X35 * | ||||||||

| BL-3000-SWI-2"-61 * | 51 | 60 | 60.30 | 60.32 | 61 | 79 | 47 | 22 | 147 | M 14X35 * | ||||||||

| BL-3000-SWI-2"-65.8 * | 65 | 65.8 | 65.8 | |||||||||||||||

| BL-3000-SWI-2"1/2-74 * BL-3000-SWI-2"1/2-77 * BL-3000-SWI-2"1/2-81 * | 150 | 64 | 80 | 76.10 | 73.02 | 74 77 81 | 98 | 58 | 24 | 170 | M 14X40 * | |||||||

| BL-3000-SWI-3"-90.5 | 100 | 76 | 90 | 88.90 | 90.5 | 116 | 70 | 28 | 190 | M 16X50 | ||||||||

(1) Empfohlener Höchstdruck | ||||||||||||||||||

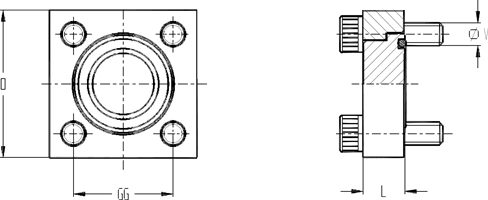

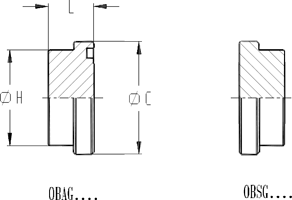

Einteilige blindflansche

ZWEITEILIGE BLINDFLANSCHE - SAE 3000 / SAE 6000

| ZWEITEILIGE BLINDFLANSCHE S.A.E. 3000 – ISO 6162-1 | |||||||||

| REF. | PN bar1 | DN | L | GG | Q | FF | O | Schrauben | |

| M | UNC | ||||||||

| BFX-OB-3000-1/2" BFX-OB-3000-3/4" | 350 | 13 19 | 15 16 | 17.5 22.3 | 38.1 47.6 | 46 52 | 54 65 | M 8X25 M 10X30 | 5/16-1"1/4 3/8-1"1/4 |

| BFX-OB-3000-1" | 315 | 25 | 18 | 26.2 | 52.4 | 59 | 70 | M 10X35 | 3/8-1"1/4 |

| BFX-OB-3000-1"1/4 * | 250 | 32 | 18 | 30.2 | 58.7 | 73 | 79.5 | M 12X35 * | 7/16-1"1/4 |

| BFX-OB-3000-1"1/2 * BFX-OB-3000-2" * | 210 | 38 51 | 18 21 | 35.7 42.9 | 69.8 77.8 | 83 97 | 94 102 | M 14X40* M 14X40* | 1/2-1"1/2 1/2-1"1/2 |

| BFX-OB-3000-2"1/2 * | 160 | 64 | 21 | 50.8 | 88.9 | 109 | 114.5 | M 14X45* | 1/2-1"3/4 |

| BFX-OB-3000-3" | 138 | 76 | 24 | 61.9 | 106.4 | 131 | 135 | M 16X50 | 5/8-2" |

| BFX-OB-3000-3"1/2 | 35 | 89 | 45 | 69.8 | 120.7 | 140 | 152 | M 16X50 | 5/8-2" |

| BFX-OB-3000-4" | 35 | 102 | 55 | 77.8 | 130.2 | 152 | 162 | M 16X50 | 5/8-2" |

(1) Empfohlener Höchstdruck | |||||||||

| ZWEITEILIGE BLINDFLANSCHE S.A.E. 6000 – ISO 6162-2 | |||||||||

| REF. | PN bar1 | DN | L | GG | Q | FF | O | Schrauben | |

| M | UNC | ||||||||

| BFX-OB-6000-1/2" | 400 | 13 | 18 | 18.2 | 40.5 | 48 | 56.5 | M 8X30 | 5/16-1"1/4 |

| BFX-OB-6000-3/4" | 19 | 21 | 23.8 | 50.8 | 60 | 71 | M 10X35 | 3/8-1"1/2 | |

| BFX-OB-6000-1" | 25 | 26 | 27.8 | 57.2 | 70 | 81 | M 12X45 | 7/16-1"3/4 | |

| BFX-OB-6000-1"1/4 * | 32 | 31 | 31.8 | 66.6 | 78 | 95 | M 14X50* | 1/2-2" | |

| BFX-OB-6000-1"1/2 | 38 | 34 | 36.5 | 79.3 | 95 | 113 | M 16X55 | 5/8-2"1/4 | |

| BFX-OB-6000-2" | 51 | 42 | 44.5 | 96.8 | 114 | 133 | M 20X70 | 3/4-2"3/4 | |

(1) Empfohlener Höchstdruck | |||||||||

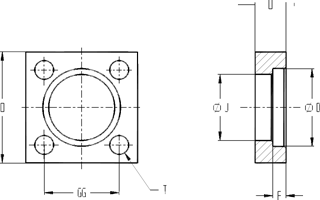

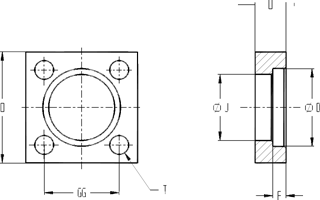

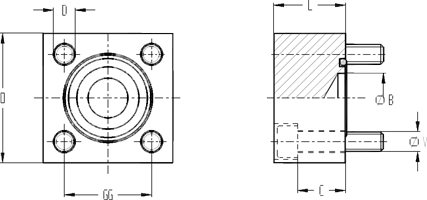

EINTEILIGE BLINDFLANSCHE - SAE 3000 / SAE 6000

| EINTEILIGE BLINDFLANSCHE S.A.E. 3000 – ISO 6162-1 | ||||||||||||||||

| REF. | PN bar1 | DN | GG | Q | FF | O | E | F | Ø H* | Schrauben | ||||||

| M | UNC | |||||||||||||||

| BFX-OB-MONO-3000-1/2" | 350 | 13 | 17.5 | 38.1 | 47 | 57 | 16 | 14 | 10 | M 8 | 5/16" | |||||

| BFX-OB-MONO-3000-3/4" | 19 | 22.3 | 47.6 | 49 | 66 | 18 | 16 | 15 | M 10 | 3/8" | ||||||

| BFX-OB-MONO-3000-1" | 315 | 25 | 26.2 | 52.4 | 53 | 71 | 19 | 16 | 18 | M 10 | 3/8" | |||||

| BFX-OB-MONO-3000-1"1/4 * | 250 | 32 | 30.2 | 58.7 | 69 | 80 | 21 | 18 | 23 | M 10 ou M 12 | 7/16" | |||||

| BFX-OB-MONO-3000-1"1/2 * | 210 | 38 | 35.7 | 69.8 | 77 | 95 | 24 | 19 | 28 | M 12 ou M 14 | 1/2" | |||||

| BFX-OB-MONO-3000-2" * | 51 | 42.9 | 77.8 | 89 | 103 | 24 | 19 | 45 | M 12 ou M 14 | 1/2" | ||||||

| BFX-OB-MONO-3000-2"1/2 * | 160 | 64 | 50.8 | 88.9 | 101 | 116 | 25 | 19 | 58 | M 12 ou M 14 | 1/2" | |||||

| BFX-OB-MONO-3000-3" | 138 | 76 | 61.9 | 106.4 | 124 | 136 | 25 | 27 | 70 | M 16 | 5/8" | |||||

| BFX-OB-MONO-3000-3"1/2 | 35 | 89 | 69.8 | 120.7 | 136 | 152 | 25 | 27 | 85 | M 16 | 5/8" | |||||

| BFX-OB-MONO-3000-4" | 35 | 102 | 77.8 | 130.2 | 146 | 162 | 25 | 27 | 95 | M 16 | 5/8" | |||||

| BFX-OB-MONO-3000-5" | 35 | 127 | 92 | 152.4 | 180 | 184 | 25 | 27 | 110 | M 16 | 5/8" | |||||

(1) Empfohlener Höchstdruck | ||||||||||||||||

| EINTEILIGE BLINDFLANSCHE S.A.E. 6000 – ISO 6162-2 | ||||||||||||||||

| REF. | PN bar1 | DN | GG | Q | FF | O | E | F | Ø H* | Schrauben | ||||||

| M | UNC | |||||||||||||||

| BFX-OB-MONO-6000-1/2" | 400 | 13 | 18.2 | 40.5 | 47 | 57 | 16 | 14 | 10 | M 8 | 5/16" | |||||

| BFX-OB-MONO-6000-3/4" | 19 | 23.8 | 50.8 | 53 | 71 | 19 | 16 | 15 | M 10 | 3/8" | ||||||

| BFX-OB-MONO-6000-1" | 25 | 27.8 | 57.2 | 66 | 80 | 24 | 18 | 22 | M 12 | 7/16" | ||||||

| BFX-OB-MONO-6000-1"1/4 * | 32 | 31.8 | 66.6 | 77 | 94 | 27 | 24 | 30 | M 14 ou M12 | 1/2" | ||||||

| BFX-OB-MONO-6000-1"1/2 | 38 | 36.5 | 79.3 | 89 | 103 | 30 | 24 | 35 | M 16 | 5/8" | ||||||

| BFX-OB-MONO-6000-2" | 51 | 44.5 | 96.8 | 123 | 135 | 35 | 31 | 48 | M 20 | 3/4" | ||||||

(1) Empfohlener Höchstdruck | ||||||||||||||||

Nutlose flansche

NUTLOSE FLANSCHE MIT GEWINDE BSPP ODER NPT - SAE 3000 / SAE 6000

| NUTLOSE FLANSCHE MIT GEWINDE BSPP ODER NPT S.A.E. 3000 –ISO 6162-1 | |||||||||||||

| REF. | PN bar1 | DN | Ø F BSP | ØA | L | GG | Q | FF | O | U | K | Ø Innengewinde | |

| M | UNC | ||||||||||||

| BAS-3000-T-BSP-1/2" | 345 | 13 | 1/2" | 13 | 36 | 17.5 | 38.1 | 47 | 57 | 16 | 19 | M 8 | 5/16" |

| BAS-3000-T-BSP-3/4" | 19 | 3/4" | 19 | 36 | 22.3 | 47.6 | 49 | 66 | 18 | 19 | M 10 | 3/8" | |

| BAS-3000-T-BSP-1" | 25 | 1" | 25 | 38 | 26.2 | 52.4 | 53 | 71 | 18 | 19 | M 10 | 3/8" | |

| BAS-3000-T-BSP-1"1/4 * | 278 | 32 | 1"1/4 | 31 | 41 | 30.2 | 58.7 | 69 | 80 | 21 | 22 | M 10 ou M 12* | 7/16" |

| BAS-3000-T-BSP-1"1/2 * | 210 | 38 | 1"1/2 | 38 | 44 | 35.7 | 69.8 | 77 | 94 | 25 | 24 | M 12 ou M 14* | 1/2" |

| BAS-3000-T-BSP-2" * | 51 | 2" | 50 | 45 | 42.9 | 77.8 | 89 | 103 | 25 | 26 | M 12 ou M 14* | 1/2" | |

| BAS-3000-T-BSP-2"1/2 * | 175 | 64 | 2"1/2 | 63 | 50 | 50.8 | 88.9 | 101 | 115 | 25 | 30 | M 12 ou M 14* | 1/2" |

| BAS-3000-T-BSP-3" | 138 | 76 | 3" | 73 | 50 | 61.9 | 106.4 | 124 | 135 | 27 | 34 | M 16 | 5/8" |

| BAS-3000-T-BSP-3"1/2 | 35 | 89 | 3"1/2 | 89 | 50 | 69.8 | 120.7 | 136 | 152 | 27 | 30 | M 16 | 5/8" |

| BAS-3000-T-BSP-4" | 102 | 4" | 99 | 50 | 77.8 | 130.2 | 146 | 162 | 27 | 30 | M 16 | 5/8" | |

(1) Empfohlener Höchstdruck. | |||||||||||||

| NUTLOSE FLANSCHE MIT GEWINDE BSPP ODER NPT S.A.E. 6000 – ISO 6162-2 | |||||||||||||

| REF. | PN bar1 | DN | Ø F BSP | ØA | L | GG | Q | FF | O | U | K | Ø Innengewinde | |

| M | UNC | ||||||||||||

| BAS-6000-T-BSP-1/2" | 400 | 13 | 1/2" | 13 | 36 | 18.2 | 40.5 | 47 | 57 | 16 | 19 | M 8 | 5/16" |

| BAS-6000-T-BSP-3/4" | 19 | 3/4" | 19 | 36 | 23.8 | 50.8 | 53 | 71 | 19 | 22 | M 10 | 3/8" | |

| BAS-6000-T-BSP-1" | 25 | 1" | 25 | 44 | 27.8 | 57.2 | 69 | 80 | 24 | 24 | M 12 | 7/16" | |

| BAS-6000-T-BSP-1"1/4 * | 32 | 1"1/4 | 31 | 44 | 31.8 | 66.6 | 77 | 94 | 27 | 25 | M 14 ou M 12* | 1/2" | |

| BAS-6000-T-BSP-1"1/2 | 38 | 1"1/2 | 38 | 51 | 36.5 | 79.3 | 89 | 106 | 30 | 28 | M 16 | 5/8" | |

| BAS-6000-T-BSP-2" | 51 | 2" | 50 | 70 | 44.5 | 96.8 | 116 | 135 | 37 | 33 | M 20 | 3/4" | |

(1) Empfohlener Höchstdruck. | |||||||||||||

NUTLOSE SCHWEISSFLANSCHE BWI - SAE 3000 / SAE 6000

| NUTLOSE SCHWEISSFLANSCHE BWI S.A.E. 3000 –ISO 6162-1 | ||||||||||||

| REF. | PN bar1 | DN | ØA | ØB | L | GG | Q | FF | U | O | Innengewinde V | |

| M | UNC | |||||||||||

| BAS-MATRI-3000- BWI-1/2"-21.5 | 345 | 13 | 21.6 | 13 | 36 | 17.5 | 38 | 47 | 16 | 57 | M 8 | 5/16" |

| BAS-MATRI-3000-BWI-3/4"-27 | 19 | 27.2 | 19 | 36 | 22.3 | 47.6 | 49 | 18 | 66 | M 10 | 3/8" | |

| BAS-MATRI-3000-BWI-1"-34 | 315 | 25 | 34.5 | 25 | 38 | 26.2 | 52.4 | 53 | 18 | 71 | M 10 | 3/8" |

| BAS-MATRI-3000-BWI-1"1/4-42* | 250 | 32 | 42.8 | 31 | 41 | 30.2 | 58.7 | 69 | 21 | 80 | M 10 ou M 12* | 7/16" |

| BAS-MATRI-3000-BWI-1"1/2-48.6* | 210 | 38 | 48.6 | 38 | 44 | 35.7 | 69.8 | 77 | 25 | 94 | M 12 ou M 14* | 1/2" |

| BAS-MATRI-3000-BWI-2"-61* | 51 | 61 | 50 | 45 | 42.9 | 77.8 | 89 | 25 | 103 | M 12 ou M 14* | 1/2" | |

| BAS-MATRI-3000-BWI-2"1/2-77* | 160 | 64 | 76.6 | 63 | 50 | 50.8 | 88.9 | 101 | 25 | 115 | M 12 ou M 14* | 1/2" |

| BAS-MATRI-3000-BWI-3"-90.5 | 138 | 76 | 89 | 73 | 50 | 61.9 | 106.4 | 124 | 27 | 135 | M 16 | 5/8" |

| BAS-MATRI-3000-BWI-3"1/2-103 | 35 | 89 | 103 | 89 | 50 | 70 | 120.7 | 137 | 27 | 153 | M 16 | 5/8" |

| BAS-MATRI-3000-BWI-4"-115 | 102 | 115 | 99 | 50 | 77.8 | 130 | 147 | 27 | 163 | M 16 | 5/8" | |

(1)Pression maxi. recommandée | ||||||||||||

| NUTLOSE SCHWEISSFLANSCHE BWI S.A.E. 6000 – ISO 6162-2 | ||||||||||||

| REF. | PN bar1 | DN | ØA | ØB | L | GG | Q | FF | U | O | Innengewinde V | |

| M | UNC | |||||||||||

| BAS-MATRI-6000-BWR-1/2"-17.5 | 400 | 13 | 17.5 | 10 | 36 | 18.2 | 40.5 | 47 | 16 | 57 | M 8 | 5.16" |

| BAS-MATRI-6000-BWI-1/2"-21.6 | 13 | 21.6 | 13 | 36 | 18.2 | 40.5 | 47 | 16 | 57 | M 8 | 5/16" | |

| BAS-MATRI-6000-BWI-3/4"-27.2 | 19 | 27.2 | 18 | 36 | 23.8 | 50.8 | 53 | 19 | 71 | M 10 | 3/8" | |

| BAS-MATRI-6000-BWI-1"-34.5 | 25 | 34.5 | 22 | 44 | 27.8 | 57.2 | 66 | 24 | 80 | M 12 | 7/16" | |

| BAS-MATRI-6000-BWI-1"1/4-42.8* | 32 | 42.8 | 28 | 44 | 31.6 | 66.7 | 77 | 27 | 94 | M 14* | 1/2" | |

| BAS-MATRI-6000-BWI-1"1/2-48.6 | 38 | 48.6 | 32 | 51 | 36.7 | 79.4 | 89 | 30 | 106 | M 16 | 5/8" | |

| BAS-MATRI-6000-BWI-2"-61 | 51 | 61 | 41 | 58 | 44.4 | 96.8 | 116 | 37 | 135 | M 20 | 3/4" | |

(1)Pression maxi. recommandée | ||||||||||||

NUTLOSE SCHWEISSFLANSCHE SWI - SAE 3000 / SAE 6000

| NUTLOSE SCHWEISSFLANSCHE SWI S.A.E. 3000 –ISO 6162-1 | |||||||||||||

| REF. | PN bar1 | DN | ØA | ØB | L | GG | Q | FF | U | K | O | Innengewinde V | |

| M | UNC | ||||||||||||

| BAS-MATRI-3000-SWI-1/2"-21.6 | 345 | 13 | 21.6 | 13 | 36 | 17.5 | 38.1 | 47 | 16 | 18 | 57 | M 8 | 5/16" |

| BAS-MATRI-3000-SWI-3/4"-27.2 | 19 | 27.2 | 19 | 36 | 22.3 | 47.6 | 49 | 18 | 18 | 66 | M 10 | 3/8" | |

| BAS-MATRI-3000-SWI-1"-34 | 25 | 34.1 | 25 | 38 | 26.2 | 52.4 | 53 | 18 | 18 | 71 | M 10 | 3/8" | |

| BAS-MATRI-3000-SWI-1"1/4-43* | 278 | 32 | 42.8 | 31 | 41 | 30.2 | 58.7 | 69 | 21 | 20 | 80 | M 10 ou M 12* | 7/16" |

| BAS-MATRI-3000-SWI-1"1/2-49* | 210 | 38 | 48.6 | 38 | 44 | 35.7 | 69.8 | 77 | 25 | 22 | 94 | M 12 ou M 14* | 1/2" |

| BAS-MATRI-3000-SWI-2"-61* | 51 | 61 | 50 | 45 | 42.9 | 77.8 | 89 | 25 | 24 | 103 | M 12 ou M 14 * | 1/2" | |

| BAS-MATRI-3000-SWI-2"1/2-77* | 175 | 64 | 76.6 | 63 | 50 | 50.8 | 88.9 | 101 | 25 | 28 | 115 | M 12 ou M 14* | 1/2" |

| BAS-MATRI-3000-SWI-3"-90.5 | 138 | 76 | 90.5 | 73 | 50 | 61.9 | 106.4 | 124 | 27 | 28 | 135 | M 16 | 5/8" |

(1) Empfohlener Höchstdruck. | |||||||||||||

| NUTLOSE SCHWEISSFLANSCHE SWI S.A.E. 6000 – ISO 6162-2 | |||||||||||||

| REF. | PN bar1 | DN | ØA | ØB | L | GG | Q | FF | U | K | O | Innengewinde V | |

| M | UNC | ||||||||||||

| BAS-MATRI-6000-SWI-1/2"-21.6 | 400 | 13 | 21.6 | 13 | 36 | 18.2 | 40.5 | 47 | 16 | 18 | 57 | M 8 | 5/16" |

| BAS-MATRI-6000-SWI-3/4"-27.2 | 19 | 27.2 | 19 | 36 | 23.8 | 50.8 | 53 | 19 | 20 | 71 | M 10 | 3/8" | |

| BAS-MATRI-6000-SWI-1"-34 | 25 | 34.1 | 25 | 44 | 27.8 | 57.2 | 66 | 24 | 22 | 80 | M 12 | 7/16" | |

(1) Empfohlener Höchstdruck. | |||||||||||||

NUTLOSE SCHWEISSFLANSCHE SOCKET WELDING MIT VOLLDURCHGANG - SAE 3000 / SAE 6000

| NUTLOSE SCHWEISSFLANSCHE „SOCKET WELDING“ MIT VOLLDURCHGANG SAE 3000 – ISO 6162-1 | |||||||||||||||||

| REF. | GG | O | Q | FF | Ø L1 | Ø A | K | U | Innengewinde | ||||||||

| BAS-3000-SWI-1/2"-20.5 BAS-3000-SWI-1/2"-21.7 | 17.5 | 54 | 38.1 | 45 | 20.5 21.7 | 13 | 13 | 20 | M 8 | ||||||||

| BAS-3000-SWI-3/4"-25.5 BAS-3000-SWI-3/4"-27.3 | 22.3 | 65 | 47.6 | 55 | 25.5 27.3 | 19 | 13 | 20 | M 10 | ||||||||

| BAS-3000-SWI-1"-30.5 BAS-3000-SWI-1"-32.5 BAS-3000-SWI-1"-34 BAS-3000-SWI-1"-35.5 | 26.2 | 70 | 52.4 | 60 | 30.5 32.5 34 35.5 | 25 | 16 | 25 | M 10 | ||||||||

| BAS-3000-SWI-1"1/4-38.5 * BAS-3000-SWI-1"1/4-40.5 * BAS-3000-SWI-1"1/4-43 * | 30.2 | 80 | 58.7 | 73 | 38.5 40.5 43 | 32 | 18 | 25 | M 12 ou M 10 (ISO) | ||||||||

| BAS-3000-SWI-1"1/2-49 * BAS-3000-SWI-1"1/2-50.4 * | 35.7 | 94 | 69.8 | 80 | 49 50.4 | 38 | 20 | 30 | M 14 ou M 12 (ISO) | ||||||||

| BAS-3000-SWI-2"-61 * BAS-3000-SWI-2"-65.8 * | 42.9 | 100 | 77.8 | 97 | 61 65.8 | 47 | 24 | 40 | M 14 ou M 12 (ISO) | ||||||||

| BAS-3000-SWI-2"1/2-74 * BAS-3000-SWI-2"1/2-77 * BAS-3000-SWI-2"1/2-81 * | 50.8 | 114 | 88.9 | 110 | 74 77 81 | 58 | 24 | 40 | M 14 ou M 12 (ISO) | ||||||||

| BAS-3000-SWI-3"-90.5 | 61.9 | 135 | 106.4 | 131 | 90.5 | 70 | 28 | 40 | M 16 | ||||||||

(1) Empfohlener Höchstdruck. | |||||||||||||||||

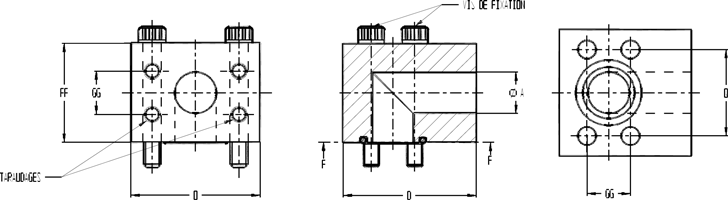

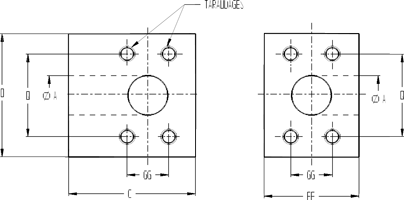

Blöcke

BEFESTIGUNGSWINKEL FÜR BLÖCKE - SAE 3000 / SAE 6000

| BEFESTIGUNGSWINKEL FÜR BLÖCKE S.A.E. 3000 – ISO 6162-1 | ||||||||||||||

| REF. | PN Bar1 | DN | Ø A | FF | O | D | Q | GG | Schraube | Innengewinde | ||||

| M | UNC | M | UNC | |||||||||||

| BLC-EQ-FIX-3000-3/8" BLC-EQ-FIX-3000-1/2" | 350 | 10 13 | 12 13 | 41 46 | 52 58 | 50 56 | 35 38.1 | 16.5 17.5 | M 8X55 M 8X60 | - 5/16"-2"1/4 | M 8 M 8 | - 5/16" | ||

| BLC-EQ-FIX-3000-3/4 | 19 | 19 | 53 | 66 | 66 | 47.6 | 22.3 | M 10X70 | 3/8"-2"3/4 | M 10 | 3/8" | |||

| BLC-EQ-FIX-3000-1" BLC-EQ-FIX-3000-1"1/4 * | 315 | 25 32 | 25 32 | 60 75 | 72 80 | 80 95 | 52.4 58.7 | 26.2 30.2 | M 10X75 M 12X90 | 3/8"-3" 7/16"-3"1/2 | M 10 M 12 * | 3/8" 7/16" | ||

| 250 | ||||||||||||||

| BLC-EQ-FIX-3000-1"1/2 * | 210 | 38 | 38 | 85 | 95 | 110 | 69.8 | 35.7 | M 14X110 | 1/2"-4"1/2 | M 14 * | 1/2" | ||

| BLC-EQ-FIX-3000-2" * BLC-EQ-FIX-3000-2"1/2 * | 51 64 | 47 58 | 100 110 | 108 118 | 110 125 | 77.7 88.9 | 42.9 50.8 | M 14X120 M 14X130 | 1/2"-5" 1/2"-5" | M 14 * M 14 * | 1/2" 1/2" | |||

| 160 | ||||||||||||||

| BLC-EQ-FIX-3000-3" | 138 | 76 | 70 | 132 | 138 | 150 | 106.4 | 61.9 | M 16X160 | 5/8"-6"1/2 | M 16 | 5/8" | ||

(1) Empfohlener Höchstdruck | ||||||||||||||

| BEFESTIGUNGSWINKEL FÜR BLÖCKE S.A.E. 6000 – ISO 6162-2 | ||||||||||||||

| REF. | PN Bar1 | DN | Ø A | FF | O | D | Q | GG | Schraube | Innengewinde | ||||

| M | UNC | M | UNC | |||||||||||

| BLC-EQ-FIX-6000-1/2" BLC-EQ-FIX-6000-3/4" | 400 | 13 19 | 13 17.5 | 50 62 | 58 73 | 56 66 | 40.5 50.8 | 18.2 23.8 | M 8X65 M 10X80 | 5/16"-2"1/2 3/8"-3"1/4 | M 8 M 10 | 5/16" 3/8" | ||

| BLC-EQ-FIX-6000-1" | 25 | 22 | 72 | 83 | 80 | 57.2 | 27.8 | M 12X90 | 7/16"-3"1/2 | M 12 | 7/16" | |||

| BLC-EQ-FIX-6000-1"1/4 * BLC-EQ-FIX-6000-1"1/2 | 32 38 | 29 35 | 80 98 | 98 115 | 95 110 | 66.6 79.3 | 31.8 36.5 | M 14X100* M 16X120 | 1/2"-4" 5/8"-5" | M 14 * M 16 | 1/2" 5/8" | |||

| BLC-EQ-FIX-6000-2" | 51 | 43 | 116 | 135 | 135 | 96.8 | 44.5 | M 20X150 | 3/4"-6" | M 20 | 3/4" | |||

(1) Empfohlener Höchstdruck | ||||||||||||||

VERTEILERBLÖCKE – L-STÜCK - SAE 3000 / SAE 6000

| VERTEILERBLÖCKE – L-STÜCK S.A.E. 3000 – ISO 6162-1 | ||||||||||

| REF. | PN Bar1 | DN | Ø A | O | FF | C | GG | Q | Innengewinde | |

| M | UNC | |||||||||

| BLC-DIST-L-3000-3/8" BLC-DIST-L-3000-1/2" | 350 | 10 13 | 12 13 | 52 58 | 41 46 | 50 56 | 16.5 17.5 | 35 38.1 | M 8 M 8 | - 5/16" |