MANULAN®

Pneumatic tubes polyurethane

General

MANULAN® tubes are made of solid polyurethane (thermoplastic polyurethane elastomer or TPU) polyester base.

They are obtained by calibrated extrusion.

If they are less durable in time than MANUril® tubes, they have acquired great importance on the market through their flexibility and their higher resistance to impacts and abrasion.

Moreover, the size of logic panels can be reduced by the low bend radius of MANULAN® tubes. MANULAN® tubes are :

- Very resistant to abrasion, wear and impacts.

- Very flexible, even in cold.

- Generators of very low pressure drops.

- Provided with good bend radius.

- Exempt of exudable plastifiers.

MANULAN® standard polyester base tubes are used in pneumatic or hydraulic logic systems and have excellent resistance to oils and hydrocarbons, but do not resist very well to acids and alcalines.

They comply with the European regulations for food contact.

On request, it can be supplied in polyether base polyurethane, the other great family of polyurethanes.

Globally, tubes in polyether base polyurethane have the opposite characteristics.

A table can be found on page 19, giving the main differences in chemical resistances of polyester and polyether base polyurethanes.

MANULAN® tubes are rigorously calibrated. for certain dimensions, they are in conformity with NFE 49 101 which defines not only dimensional tolerances but also working pressures according to safety factors with regards to working temperature, along with tests (moisture absorption, aging, flexibility) defining their use.

They are made from 100% virgin material.

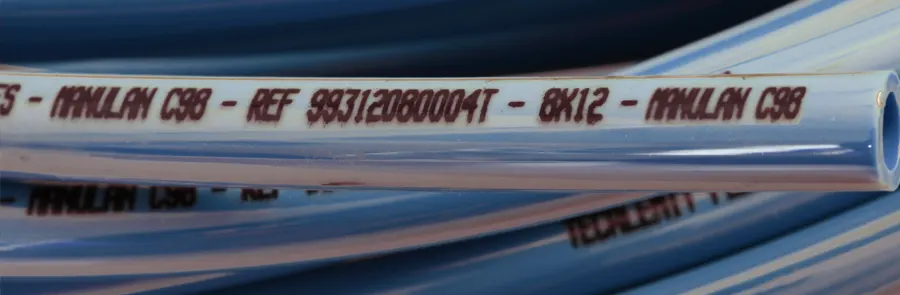

Marking of tubes is as follows : “tecalemit flexibles - part N° - manulan - ID x OD - batch N°”

Part N°

Polyurethane polyester base calibrated pneumatic tube according to NF E 49 101

| Part n° | outer diameter (mm) | inner diameter (mm) | wall thickness (mm) | non-burst pressure limit 20°c (bars) | working pressure at 20°c (bars) | weight (gr/m) | bend radius (mm) | tolerance on outer diameter (mm) | tolerance on inner diameter (mm) | std colours |

| 9930318000X | 3 | 1,8 | 0,6 | 42 | 14 | 6,70 | 15 | +0,10/-0,10 | +0,10/-0,05 | On request |

| 9930425000X | 4 | 2,5 | 0,75 | 46 | 15 | 9,50 | 20 | +0,10/-0,10 | +0,10/-0,05 | white, blue, natural yellow, black, red, green |

| 9930503000X | 5 | 3 | 1 | 39 | 13 | 15,3 | 20 | +0,10/-0,10 | +0,10/-0,05 | On request |

| 9930604000X | 6 | 4 | 1 | 30 | 10 | 19,2 | 30 | +0,10/-0,10 | +0,10/-0,05 | white, blue, natural yellow, black, red |

| 9930855000X | 8 | 5,5 | 1,25 | 27 | 9 | 32,3 | 30 | +0,10/-0,10 | +0,10/-0,05 | white, blue, natural yellow, black, red |

| 9931007000X | 10 | 7 | 1,5 | 27 | 9 | 48,8 | 40 | +0,15/-0,15 | +0,10/-0,07 | blue, natural, black |

| 9931208000X | 12 | 8 | 2 | 30 | 10 | 76,7 | 50 | +0,15/-0,15 | +0,10/-0,07 | blue, natural, black |

| 9931495000X | 14 | 9,5 | 2,25 | 30 | 10 | 102 | 55 | +0,15/-0,15 | +0,10/-0,07 | On request |

Table of comparison

Table of comparison between polyether and polyester base polyurethanes

| Chemical | Polyester base | Polyether base | |||

| 20°C | 60°C | 20°C | 60°C | ||

| Water | fresh water | 1 | 2 | 1 | 1 |

| sea water | 1 | 2 | 1 | 1 | |

| Anhydride acids diluted | acetic acid 3% | 3 | 4 | 1 | 2 |

| lactic acid 3% | 3 | 4 | 1 | 2 | |

| boric acid 3% | 1 | 3 | 1 | 2 | |

| formic acid 3% | 2 | 3 | 1 | 2 | |

| Mineral acids diluted | citric acid 3% | 2 | 4 | 1 | 2 |

| sodium sulphide 3% | 2 | 3 | 1 | 2 | |

| phosphoric acid 3% | 2 | 3 | 1 | 2 | |

| chlorhydric acid 3% | 4 | 4 | 1 | 2 | |

| sulfuric acid 3% | 4 | 4 | 1 | 2 | |

| battery acid | 4 | 4 | 4 | 4 | |

| nitric acid 3% | 4 | 4 | 4 | 4 | |

| Oxidation solutions | sodium nitrate 3% | 1 | 2 | 1 | 2 |

| sodium hypochlorite 3% | 3 | 4 | 2 | 3 | |

| javel water 3% | 2 | 3 | 1 | 2 | |

| Reducing solutions | sodium sulphite 3% | 1 | 2 | 1 | 2 |

| Alkaline solutions | calcium hydroxide | 1 | 2 | 1 | 2 |

| aqueous soda 3% | 1 | 2 | 1 | 2 | |

| caustic soda 3% | 2 | 3 | 1 | 2 | |

| triethanolamine 3% | 2 | 2 | 1 | 2 | |

| Alcohols | methanol | 3 | 2 | ||

| Ethanol | 2 | 1 | |||

| Isopropanol | 2 | 1 | |||

| ASTM test oils | astm 1 oil | 1 | 1 | ||

| astm 2 oil | 1 | 2 | 1 | 2 | |

| astm 3 oil | 1 | 2 | 1 | 2 | |

| Miscellaneous | anti-freeze | 2 | 3 | 1 | 2 |

| brake fluid | 4 | 4 | 4 | 4 | |

| ethyl acetate | 2 | 3 | |||

Ratio T°/Pressure

Table of working pressure ratios of MANULAN® tubes according to working temperature

| T(°C) | -40° to+20° | 30° | 40° | 50° | 60° |

| Pressure (%) | 100% | 83% | 72% | 64% | 47% |

Les valeurs des ratios de pression de service en fonction de la température indiquée ci-dessus ne représentent qu’une moyenne des résultats obtenus à partir des pressions d’éclatement divisées par un coefficient de sécurité, étant entendu que celles-ci sont variables suivant le diamètre et l’épaisseur des tubes.

Codification

MANULAN® part numbers are mnemonic are are composed as follows

| XXX | XX | XX | XXX | X | X | |

| MANULAN (PU) Polyurethane | 993 | Outer diameter | Inner diameter | Length | Colour | Packaging |

| 000 (reel) | 1 black | T Reel | ||||

| 025 (25m) | 2 white | S Sachet | ||||

| 050 (50m) | 3 yellow | B Box | ||||

| 100 (100m) | 4 blue | |||||

| 5 red | ||||||

| 6 green | ||||||

| 7 natural | ||||||

Example :

for a box of 100 metres of yellow 4x2.5 MANULAN® tube

| 993 | 04 | 25 | 100 | 3 | B |

| MANULAN (PU) Polyurethane | Outer diameter | Inner diameter | Length | Colour | Packaging |

| 4mm | 2,5mm | 100m | yellow | Box |

In general MANULAN® tubes are produced in long lengths on wooden reels. they are then repackaged in sachets, boxes or on smaller capacity reels in multiples of 25 metres lengt

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR