Recoverable Fitting Technical Guide

Terminology - Piping Fabrication - Fitting Assembly

Pipes:

Pipes are conduits that can be made of metal, plastic, or rubber.

Fittings:

Fittings are metal pieces that are attached to the ends of pipes to allow them to connect to other pipes or devices.

They belong to three main families:

A: with inner rubber lining meeting SAE 100 standards: R1AT - R5C - R5R.

B: with inner thermoplastic lining: TTA - TTK.

C: with inner PTFE lining such as THP1.

The reinforcement (or reinforcement carcass) of the one or the other is composed of:

- one or more textile braids.

- a steel braid.

- combination of two of these formulas.

This architecture is defined in the presentation text of all our listed hoses (Hydraulic Hose Catalogue).

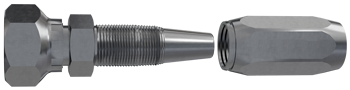

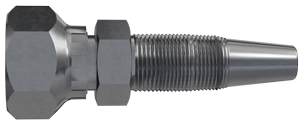

Nipples:

Zinc-plated and double-chromated for the standard: they can be supplied, upon request, in stainless steel.

Depending on the desired equipment and the pipe used, they have a different back part depending on the mode of anchoring on the pipe.

| Screw Fittings for Pipes: T510 - T511 - T111 | Teflon Fittings for Pipe: THP1 |

|  |

Pipe Cutting:

T111 - T510 - T511:

Cut square with a very fine toothed metal saw (or preferably a chainsaw), moderately clamping the pipe in a vice.

TPH1:

Same procedure as above, but prewrap the pipe with adhesive tape at the cutting line, so as to avoid the braid from "frizzing".

TTA - TTK:

Cut the pipe squarely with a sharp, fine blade or with a Ref 28908631 Metal Cutting Pliers (Tecalemit Flexible Pipe Pneumatics Catalogue).

Our cutting and stripping machines save a lot of time and ensure a neat, perfectly square cut, without any effort from the operator.

Assembly of recoverable fitting :

FOR T111-T510-T511

The fitting of the hose end is done on the covering of the pipe that must not be stripped

The length to be stripped is determined on each socket by the measurement between its rear face and a mark engraved on its exterior.

Brush braid or sheet before mounting the fittings.

Moderately tighten the socket in a vice.

Screw the pipe into the socket (left-hand thread) to the stop.

Then unscrew a quarter turn (important).

Abundantly oil the inside of the pipe and the part of the nipple intended to penetrate it (nipple).

Screw the nipple into the socket (right-hand thread) until the six corners of this nipple are 0.5 mm from the front face of the socket.

FOR TTA-TTK

Do not uncover.

Assemble the fitting as for T510, T511 and T111

IMPORTANT:

For piping intended to convey gases,

-the outer coating of the pipe will be micro-perforated in our workshops.

-the fittings will be carefully degreased before assembly.

-the assembly will be done with pure water.

The service pressures indicated in our tables are variable for hydraulic fluids.

The service pressures for flammable gas fluids are clearly lower than the indicated pressures.

Consult us depending on the operating pressure and the gas conveyed.

Flexible hoses conveying pressurized gases will be fixed to neutralize the whip effect caused by a

possible break.

All pipelines will be cleaned internally after manufacture.

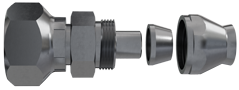

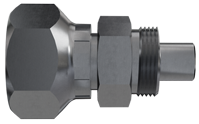

FOR THP1

Thread two sockets back-to-back onto the pipe at the end that has been crimped by braiding,

Place the conical ring between the tube and braid so that the THP1 tube abuts the inner shoulder of this ring.

Thoroughly lubricate the socket thread with mineral oil.

Push the pipe equipped with its conical ring to the bottom of the fitting.

Screw the socket onto the fitting.

Leave a gap of 0.8 mm between the hexagon of the fitting and the socket.

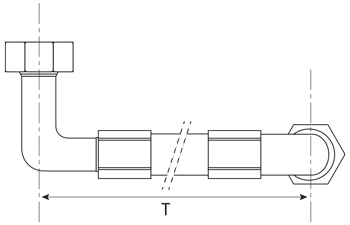

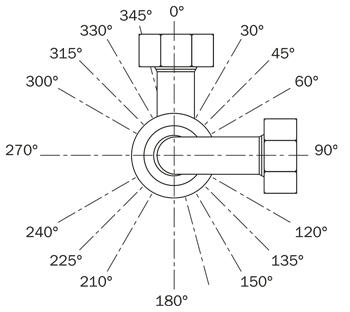

Orientation of Ends:

The angle of orientation of the ends is that chosen by convention in the following way:

A: Look at the piping from the front by any of its ends.

B: Starting from the nearest end and turning counterclockwise, consider the angle formed with the second end.

Tolerance on the angle of orientation according to the length T:

Length T ≤ 610 tolerance = ± 3°

Length T > 610 tolerance = ± 5°

|  |

Compatibility of Nipples & Sockets:

| ENDPLUG PROFILES | |||

| NIPPLES | HOSES | SOCKETS | |

| T510 R5C T511 R5R | Non-skive | |

|  | ||

| TTA - TTK | Non-skive | ||

|  | ||

| T111 1SN | Non-skive | |

|  | ||

| THP1 |  |  |

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR