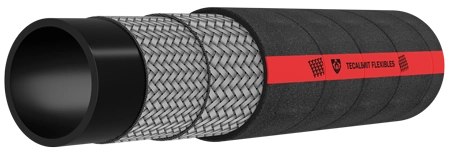

Water delivery rubber hoses

| 111 |

| |

Robust and resistant to temperature, hose 111 is destined for delivery of industrial waters.

Its outer cover is a mixture of SBR / EPDM rubbers resisting aging and ultra-violet effects as well as numerous detergents and diluted acids.

His 6 textile plies gives it excellent resistance to round.

Technical specifications:

Inner tube : SBR smooth rubber

Reinforcement : 6 textile plies

Outer cover : SBR / EPDM rubber

Outer finish : wrapped

Temperature : 90°C max

Production length : 60 m up to diameter 150, 40 m above

Colour : black

Marking : TECALEMIT - PART N° - REFOULEMENT 10 BAR - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 111 100 | 102 | 4” | 120 | 9 | 10 | 30 | 900 | 4,3 |

| 111 127 | 127 | 5” | 147 | 10 | 10 | 30 | 1100 | 5,4 |

| 111 150 | 152 | 6” | 172 | 10 | 9,5 | 38 | 1350 | 6,3 |

| 111 200 | 203 | 8” | 225 | 11 | 10 | 30 | 1800 | 8,11 |

Possible end-fittings : Guillemin, flange, camlock, storz

See also 111, 131, 119

| 113 |

| |

Robust and resistant to temperature, hose 113 is destined for delivery of industrial waters.

Its outer cover is a mixture of SBR / EPDM rubbers resisting aging and ultra-violet effects as well as numerous detergents and diluted acids.

Technical specifications:

Inner tube : SBR smooth rubber

Reinforcement : textile plies

Outer cover : SBR / EPDM rubber

Outer finish : wrapped

Temperature : 90°C

Production length : 20 meters, possibility of 60 meters on request

Colour : red

Marking : TECALEMIT - PART N° - REFOULEMENT 10 BAR - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 113 13 | 13 | 1/2” | 21 | 4 | 10 | 30 | 120 | 0,25 |

| 113 16 | 16 | 5/8” | 24 | 4 | 10 | 30 | 160 | 0,35 |

| 113 19 | 19 | 3/4” | 27 | 4 | 10 | 30 | 190 | 0,40 |

| 113 22 | 22 | 7/8” | 30 | 4 | 10 | 30 | 220 | 0,45 |

| 113 25 | 25,4 | 1” | 33 | 4 | 10 | 30 | 254 | 0,50 |

| 113 30 | 30 | 1” 3/16 | 39 | 4 ,5 | 10 | 30 | 300 | 0,67 |

| 113,32 | 32 | 1” 1/4 | 40 | 4 | 10 | 30 | 320 | 0,75 |

| 113 35 | 35 | 1” 3/8 | 45 | 5 | 10 | 30 | 350 | 0,80 |

| 113 40 | 40 | 1” 9/16 | 50 | 5 | 10 | 30 | 400 | 0,90 |

| 113 45 | 45 | 1” 3/4 | 55 | 5 | 10 | 30 | 450 | 1,0 |

| 113 50 | 50,8 | 2” | 61 | 5,1 | 10 | 30 | 508 | 1,10 |

| 113 55 | 55 | 2 3/16 | 67 | 5 | 10 | 30 | 560 | 1,3 |

| 113 60 | 60 | 2” 3/8 | 71 | 5,5 | 10 | 30 | 600 | 1,5 |

| 113 70 | 70 | 2” 3/4 | 81 | 5,5 | 10 | 30 | 700 | 1,7 |

| 113 75 | 75 | 3” | 89 | 7 | 10 | 30 | 750 | 2,2 |

| 113 80 | 80 | 3” 5/32 | 92 | 6 | 10 | 30 | 800 | 2.2 |

| 113 90 | 90 | 3” 1/2 | 104 | 7 | 10 | 30 | 900 | 3,00 |

| 113 100 | 101,6 | 4” | 115 | 6.7 | 10 | 30 | 101 | 3,10 |

| 113 110 | 110 | 4” 11/32 | 122 | 6 | 10 | 30 | 1100 | 2,91 |

| 113 120 | 120 | 4” 23/32 | 134 | 7 | 10 | 30 | 1200 | 3,50 |

| 113 127 | 127 | 5” | 141 | 7 | 10 | 30 | 1270 | 4,20 |

| 113 150 | 152,4 | 6” | 165 | 6,3 | 10 | 30 | 1254 | 4,18 |

| 113 168 | 168 | 6” 5/8 | 184 | 8 | 10 | 30 | 1400 | 6,5 |

| 113 200 | 203,2 | 8” | 218 | 7,4 | 10 | 30 | 2032 | 6,75 |

| 113 219 | 219 | 8” 3/4 | 235 | 8 | 10 | 30 | 2200 | 8,2 |

| 113 250 | 254 | 10” | 272 | 9 | 10 | 30 | 2504 | 10,22 |

Possible end-fittings : Guillemin, flange, camlock, storz

See also 111, 131

| 117 |

| |

Water delivery hose 117 is used on fishing vessel decks.

Its EPDM rubber cover ensures long life and flexibility in cold temperatures.

Its thickness gives excellent dimensional stability.

A high quality water delivery hose, it is used for many chemical products..

Technical specifications:

Inner tube : white EPDM rubber

Reinforcement : 2 textile plies

Outer cover : EPDM rubber

Outer finish : wrapped

Temperature : 95°C maximum

Production lengths : 20 meters

Colour : red

Marking : TECALEMIT - PART N° - LE BIGOUDEN - REFOULEMENT 7 BAR - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 117 30 | 30 | 1” 3/16 | 42 | 6 | 7 | 31 | 240 | 1,0 |

| 117 35 | 35 | 1” 3/8 | 47 | 6 | 7 | 31 | 280 | 1,10 |

| 117 40 | 40 | 1” 9/16 | 52 | 6 | 7 | 31 | 320 | 1,25 |

| 117 50 | 50,8 | 2” | 62 | 6 | 7 | 31 | 406 | 1,42 |

| 117 60 | 60 | 2” 3/8 | 72 | 6 | 7 | 31 | 540 | 1,7 |

Possible end-fittings : Guillemin

See also 113, 119

| 119 |

| |

The water delivery hose 119 has excellent flexibility even during very low colds. Its dimensional stability is ideal also.

A high quality water delivery hose, it is appreciated in the shipping industry, in mussel farming (its resistance to abrasion is excellent) and in fishing.

It is aso used for many diluted acids.

Technical specifications:

Inner tube : parablond rubber

Reinforcement : 2 textile plies

Outer cover : parablond rubber

Admissible negative pressure : 0.9 bar

Outer finish : wrapped

Temperature : 60°C maximum

Production lengths : 20 meters

Particularity : very flexible

Colour : light beige

Marking : NONE

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 119 19 | 19 | 3/4” | 28 | 4.5 | 5 | 15 | 152 | 0,36 |

| 119 25 | 25,4 | 1” | 34 | 4.5 | 5 | 15 | 203 | 0,50 |

| 119 30 | 30 | 1”3/16 | 41 | 5 | 5 | 15 | 240 | 0,65 |

| 119 32 | 32 | 1” 1/4 | 42 | 5 | 5 | 15 | 260 | 0,70 |

| 119 35 | 35 | 1”3/8 | 46 | 5 | 5 | 15 | 280 | 0,75 |

| 119 40 | 40 | 1”9/16 | 52 | 6 | 5 | 15 | 320 | 0,95 |

| 119 45 | 45 | 2”3/4 | 57 | 6 | 5 | 15 | 360 | 1,00 |

| 119 50 | 50,8 | 2” | 62 | 6 | 5 | 15 | 406 | 1,10 |

| 119 57 | 57 | 2”1/4 | 69 | 6 | 5 | 15 | 456 | 1,20 |

| 119 60 | 60 | 2”3/8 | 72 | 6 | 5 | 15 | 480 | 1,30 |

| 119 80 | 80 | 3”5/32 | 92 | 6 | 5 | 15 | 640 | 2,20 |

| 119 100 | 101,6 | 4” | 114 | 6.5 | 5 | 15 | 813 | 2,80 |

Possible end-fittings : Threaded, guillemin

See also 113, 117

| 121 |

| |

Produced to order or available in stocked lengths, hose 121 is the ideal mobile moto-pump suction hose.

It has an excellent bend radius and flexible cuff-ends allowing easy and sure mounting of end-fittings.

It reamins flexible even in very cold temperatures.

Iit accepts maximum negative pressure.

Technical specifications:

Inner tube : smooth SBR rubber

Reinforcement : textile plies and metal spiral

Outer cover : abrasion and weather resistant SBR rubber

Outer finish : wrapped and corrugated. flexible cuff-ends

Temperature : 90°C

Production lengths : all lengths

Colour : black

Particularity : possibility of belled or oversize cuff-ends

Marking : NONE

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 121 25 | 25,4 | 1” | 34 | 4.5 | 5 | 15 | 76,2 | 0.6 |

| 121 30 | 30 | 1” 3/16 | 39 | 4.5 | 5 | 15 | 90 | 0.7 |

| 121 35 | 35 | 1” 3/8 | 44 | 4.5 | 5 | 15 | 105 | 0.9 |

| 121 40 | 40 | 1” 9/16 | 49 | 4.5 | 5 | 15 | 120 | 1.0 |

| 121 45 | 45 | 1” 3/4 | 54 | 4.5 | 5 | 15 | 135 | 1.3 |

| 121 48 | 48 | 1” 7/8 | 58 | 5 | 5 | 15 | 140 | 1,3 |

| 121 50 | 50,8 | 2” | 60 | 5 | 5 | 15 | 152 | 1.5 |

| 121 55 | 55 | 2” 3/16 | 67 | 6 | 5 | 15 | 160 | 1.7 |

| 121 60 | 60 | 2” 3/8 | 70 | 5 | 5 | 15 | 180 | 1.8 |

| 121 65 | 63,5 | 2” 1/2 | 76 | 5.5 | 5 | 15 | 190 | 1.9 |

| 121 70 | 70 | 2” 3/4 | 82 | 6 | 5 | 15 | 210 | 2.0 |

| 121 75 | 76,2 | 3” | 88 | 6 | 5 | 15 | 305 | 2.3 |

| 121 80 | 80 | 3” 5/32 | 93 | 6.5 | 5 | 15 | 400 | 2.9 |

| 121 90 | 90 | 3” 9/16 | 103 | 6.5 | 5 | 15 | 450 | 3.4 |

| 121 100 | 101,6 | 4” | 116 | 7 | 5 | 15 | 508 | 4.0 |

| 121 110 | 110 | 4” 11/32 | 124 | 7 | 5 | 15 | 660 | 4.5 |

| 121 120 | 120 | 4” 23/32 | 136 | 8 | 5 | 15 | 720 | 4.9 |

| 121 125 | 127 | 5” | 143 | 8 | 5 | 15 | 762 | 5.7 |

| 121 150 | 152,4 | 6” | 168 | 8 | 5 | 15 | 915 | 8.3 |

| 121 168 | 168 | 6” 5/8 | 188 | 10 | 5 | 15 | 1300 | 10.0 |

| 121 200 | 203,2 | 8” | 223 | 10 | 5 | 15 | 1219 | 13.0 |

| 121 250 | 254 | 10” | 278 | 12 | 5 | 15 | 1524 | 20.0 |

| 121 300 | 304,8 | 12” | 333 | 14 | 5 | 15 | 1829 | 26.0 |

| 121 400 | 406,4 | 16” | 436 | 15 | 5 | 15 | 2500 | 39.0 |

Possible end-fittings : Guillemin, flange, globe-type

See also 123

| 131 |

| |

This lay-flat hose intended for water delivery is mainly used for submersible pumps in industry and public works.

Its light weight and sturdiness are its main qualities, along with its temperature resistance allowing use in hot regions during summer.

Technical specifications:

Inner tube : black SBR rubber

Reinforcement : 2 or 4 textile plies according to diameter

Outer cover : abrasion and weather resistant SBR rubber

Outer finish : wrapped

Temperature : 90°C max

Production lengths : Ø 200 : 45 m, Ø 250 & 300 : 25 m

Ø 400 : 12 m, above : 6 m

Colour : black

Particularity : can be rolled flat

Marking : TECALEMIT - PART N° - REFOULEMENT EAU 5 BAR - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 131 45 | 45 | 1” 3/4 | 51 | 3 | 5 | 15 | - | 0,5 |

| 131 50 | 50 | 2” | 58 | 3 | 5 | 15 | - | 0,96 |

| 131 60 | 60 | 2” 3/8 | 67 | 3.5 | 5 | 15 | - | 1,00 |

| 131 65 | 63,5 | 2” 1/2 | 70 | 3.5 | 5 | 15 | - | 1,05 |

| 131 70 | 70 | 2” 3/4 | 77 | 3.5 | 5 | 15 | - | 1,15 |

| 131 75 | 76,2 | 3” | 83 | 3.5 | 5 | 15 | - | 1,27 |

| 131 80 | 80 | 3” 5/32 | 88 | 10.0 | 5 | 15 | - | 1,50 |

| 131 90 | 90 | 3” 9/16 | 98 | 3.5 | 5 | 15 | - | 1,62 |

| 131 100 | 101,6 | 4” | 108 | 4 | 5 | 15 | - | 1,34 |

| 131 110 | 110 | 4” 11/32 | 118 | 4 | 5 | 15 | - | 1,5 |

| 131 114 | 114,3 | 4” 1/2 | 122 | 4 | 5 | 15 | - | 1,7 |

| 131 120 | 120 | 4” 23/32 | 128 | 4 | 5 | 15 | - | 2,00 |

| 131 140 | 140 | 5” 1/2 | 150 | 5 | 5 | 15 | - | 2,3 |

| 131 150 | 152,4 | 6” | 162 | 4 | 5 | 15 | - | 3,18 |

| 131 168 | 168 | 6” 5/8 | 177 | 4,5 | 5 | 15 | - | 3,50 |

| 131 200 | 203,2 | 8” | 212 | 5 | 5 | 15 | - | 3,81 |

| 131 219 | 219 | 8” 5/8 | 229 | 5 | 5 | 15 | - | 5 |

| 131 250 | 254 | 10” | 265 | 5.5 | 5 | 15 | - | 6,28 |

| 131 273 | 273 | 10” 3/4 | 283 | 5 | 5 | 15 | - | 6,1 |

| 131 300 | 304,8 | 12” | 316 | 5.5 | 5 | 15 | - | 7,1 |

| 131 323 | 323 | 12” 3/4 | 335 | 6 | 5 | 15 | - | 8 |

| 131 386 | 386 | 15” 3/4 | 402 | 8 | 5 | 15 | - | 9 |

Possible end-fittings : globe-type, flange

See also 132, 277

| 141 | |

| DIN 13411 | |

Extremely robust, hose 141 is intended for industrial water suction.

With 4 textile layers, it accepts high peak pressures and can be used for delivery where a low bend radius is required.

iIt can accept negative pressure over 0.9 bar.

Its resistance to abrasion and aging in water are excellent.

In diameter 45, 70 and 110, it allows the production of suction lengths NF EN ISO 14557 (formerly NF S 61 113) for civil protection equipment.

Technical specifications:

Inner tube : smooth SBR rubber

Reinforcement : 4 textile plies and metal spiral

Outer cover : abrasion and weather resistant SBR rubber

Admissible negative pressure : 0.9 bar

Outer finish : wrapped

Temperature : 90°C maximum

Particularity : cuff-ends possible

Production lengths : 20 or 40 meters

Colour : black

Marking : ECALEMIT - PART N° - ASPIRATION REFOULEMENT - 10 BAR - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 141 19 | 19 | 3/4” | 30 | 5.5 | 10 | 30 | 76 | 0,64 |

| 141 25 | 25,4 | 1” | 37 | 5.5 | 10 | 30 | 102 | 0,86 |

| 141 30 | 30 | 1” 3/16 | 41 | 5.5 | 10 | 30 | 120 | 0,90 |

| 141 35 | 35 | 1” 3/8 | 47 | 6 | 10 | 30 | 140 | 1,2 |

| 141 40 | 40 | 1” 9/16 | 53 | 6.5 | 10 | 30 | 160 | 1,5 |

| 141 42 | 42 | 1” 21/32 | 55 | 6.5 | 10 | 30 | 168 | 1,4 |

| 141 45 | 45 | 1” 3/4 | 57 | 6 | 10 | 30 | 180 | 1,5 |

| 141 50 | 50,8 | 2” | 63 | 6.5 | 10 | 30 | 203 | 1,8 |

| 141 55 | 55 | 4” 11/32 | 70 | 6.5 | 10 | 30 | 220 | 2,3 |

| 141 60 | 60 | 2” 3/8 | 74 | 7 | 10 | 30 | 240 | 2,4 |

| 141 65 | 63,5 | 2” 1/2 | 77 | 7 | 10 | 30 | 254 | 2,4 |

| 141 70 | 70 | 2” 3/4 | 84 | 7 | 10 | 30 | 315 | 2,7 |

| 141 75 | 76,2 | 3” | 91 | 7.5 | 10 | 30 | 343 | 3,2 |

| 141 80 | 80 | 3” 5/32 | 96 | 8 | 10 | 30 | 360 | 3,5 |

| 141 90 | 90 | 3” 1/2 | 106 | 8 | 10 | 30 | 405 | 3,9 |

| 141 100 | 101,6 | 4” | 118 | 8 | 10 | 30 | 508 | 4,5 |

| 141 110 | 110 | 4”11/32 | 128 | 9 | 10 | 30 | 550 | 5,4 |

| 141 120 | 120 | 4” 23/32 | 138 | 9 | 10 | 30 | 600 | 6,0 |

| 141 125 | 127 | 5” | 145 | 9 | 10 | 30 | 635 | 6,4 |

| 141 140 | 140 | 5” 1/2 | 160 | 10 | 10 | 30 | 700 | 8,2 |

| 141 150 | 152,4 | 6” | 172 | 10 | 10 | 30 | 762 | 8,7 |

| 141 168 | 168 | 6” 5/8 | 190 | 11 | 10 | 30 | 924 | 10,5 |

| 141 200 | 203,2 | 8” | 229 | 13 | 10 | 30 | 1118 | 15,2 |

| 141 250 | 254 | 10” | 280 | 13 | 10 | 30 | 1524 | 18,3 |

| 141 300 | 304 | 12 | 329 | 12.5 | 10 | 30 | 1900 | 20,5 |

Possible end-fittings : Guillemin, flange, cam-lock, storz

See also 142

| 142 |

| |

Extremely robust, hose 142 is intended for industrial water suction.

With its 4 textile layers, it can accept high pressure peaks and is used in delivery where a low bend radius is required.

It can accept negative pressures above 0.9 bar.

Its resistance to abrasion and aging in water are excellents.

Technical specifications:

Inner tube : smooth SBR rubber

Reinforcement : 4 textile plies and metal spiral

Outer cover : abrasion and weather resistant SBR rubber

Admissible negative pressure : 0.9 bar

Outer finish : wrapped

Temperature : 90°C maximum

Particularity : cuff-ends possible

Production lengths : 20 or 40 meters

Colour : black

Marking : TECALEMIT - PART N° - ASPIRATION REFOULEMENT - 5 BAR - PRODUCTION DATE - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 142 19 | 19 | 3/4 | 30 | 5,5 | 5 | 15 | 76 | 0,7 |

| 142 25 | 25 | 1 | 37 | 6 | 5 | 15 | 102 | 0,8 |

| 142 40 | 40 | 1 9/16 | 50 | 5 | 5 | 15 | 160 | 1,2 |

| 142 45 | 45 | 1 3/4 | 55 | 5 | 5 | 15 | 180 | 1,4 |

| 142 50 | 50,8 | 2” | 62 | 6 | 5 | 15 | 210 | 1,67 |

| 142 55 | 55 | 2” 11/32 | 69 | 6 | 5 | 15 | 220 | 1,62 |

| 142 60 | 60 | 2” 3/8 | 71 | 5,5 | 5 | 15 | 240 | 1,90 |

| 142 70 | 70 | 2 3/4 | 82 | 6 | 5 | 15 | 315 | 2,2 |

| 142 75 | 76,2 | 3” | 87 | 6 | 5 | 15 | 342 | 2,40 |

| 142 80 | 80 | 3” 5/32 | 92 | 6 | 5 | 15 | 360 | 2,76 |

| 142 100 | 101,6 | 4” | 116 | 7 | 5 | 15 | 457 | 4,11 |

| 142 105 | 105 | 4 1/8 | 120 | 7,5 | 5 | 15 | 460 | 4,5 |

| 142 110 | 110 | 4”11/32 | 125 | 7,5 | 5 | 15 | 495 | 5 |

Possible end-fittings : Guillemin, flange, cam-lock, storz

See also 141

| 162 |

| |

Hose 162 is intended for cooling circuits of thermal engines.

Its inner tube is resistant to anti-freeze. it is flexible and light.

Possibility of cropping to 1 metre lengths in production.

Technical specifications:

Inner tube : smooth EPDM rubber

Reinforcement : 2 textile plies

Outer cover : EPDM rubber

Outer finish : wrapped

Temperature : - 30°C to 120°C

Production lengths : 40 meters

Colour : black

Marking : TECALEMIT - PART N° - EAU CHAUDE - 3 BAR - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 162 13 | 12,7 | 1/2” | 20 | 3.5 | 3 | 12 | 127 | 0,28 |

| 162 16 | 15,4 | 5/8” | 24 | 4 | 3 | 12 | 154 | 0,6 |

| 162 19 | 19 | 3/4” | 27 | 4 | 3 | 12 | 190 | 0,41 |

| 162 25 | 25,4 | 1” | 34 | 4,5 | 3 | 12 | 254 | 0,58 |

| 162 30 | 30 | 1” 3/16 | 38 | 4 | 3 | 12 | 300 | 0,61 |

| 162 35 | 35 | 1” 3/8 | 43 | 4 | 3 | 12 | 350 | 0,70 |

| 162 40 | 40 | 1” 9/16 | 49 | 4 ,5 | 3 | 12 | 400 | 0,93 |

| 162 45 | 45 | 1” 3/4 | 53 | 4 | 3 | 12 | 450 | 0,97 |

| 162 50 | 50,8 | 2” | 60 | 5 | 3 | 12 | 508 | 1,19 |

| 162 60 | 60 | 2” 3/8 | 70 | 5 | 3 | 12 | 600 | 1,50 |

| 162 65 | 63,5 | 2” 1/2 | 73 | 5 | 3 | 12 | 635 | 1,60 |

| 162 70 | 70 | 2” 3/4 | 80 | 5 | 3 | 12 | 700 | 1,70 |

| 162 75 | 76,2 | 3” | 86 | 5 | 3 | 12 | 762 | 1,90 |

| 162 80 | 80 | 3” 5/32 | 90 | 5 | 3 | 12 | 800 | 2,1 |

| 162 90 | 90 | 3” 9/16 | 102 | 6 | 3 | 12 | 900 | 2,58 |

| 162 100 | 101,6 | 4” | 114 | 6 | 3 | 12 | 1016 | 2,7 |

| 162 110 | 110 | 4” 11/32 | 122 | 6 | 3 | 12 | 1100 | 3,1 |

Possible end-fittings : Threaded

See also 163

| 163 | |

| DIN 73411 | |

The hose 163 is intended for hot water connections for thermal engine cooling systems.

Its inner tube is resistant to glycol and glycol solutions.

This hose is manufactured continuously, its outer-cover is smooth and are marked by white ink projection.

Compliant with DIN 73411, the hose can be produced according to SAE J20 R3.

Technical specifications:

Inner tube : smooth EPDM rubber

Reinforcement : 1 textile braid

Outer cover : EPDM rubber

Outer finish : smooth

Temperature : - 40°C to 125°C

Production lengths : 50 meters and variable

Colour : black

Marking : TECALEMIT - PART N° - EAU CHAUDE/HOT WATER - DIN 73411 - EPDM - DIA. PS/WP - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 163 6x12 | 6 | 1/4" | 12.0 | 3.0 | 10 | 30 | 60 | 0,12 |

| 163 7x13 | 7 | 13.0 | 3 | 10 | 30 | 60 | 0,13 | |

| 163 8x14 | 8 | 5/16" | 14.0 | 3.0 | 10 | 30 | 80 | 0,15 |

| 163 10x16 | 10 | 3/8" | 16.0 | 3.0 | 10 | 30 | 100 | 0,18 |

| 163 12x19 | 12 | 1/2" | 19.0 | 3.5 | 10 | 30 | 120 | 0,20 |

| 163 14x21 | 14 | 21.0 | 3.5 | 10 | 30 | 140 | 0,22 | |

| 163 15x23 | 15 | 23.0 | 4 | 10 | 30 | 150 | 0,28 | |

| 163 16x23 | 16 | 5/8" | 23.0 | 3,5 | 10 | 30 | 160 | 0,25 |

| 163 19x26 | 19 | 3/4 " | 26.0 | 3,5 | 10 | 30 | 190 | 0,29 |

| 163 22x29 | 22 | 7/8” | 29 | 3,5 | 10 | 30 | 200 | 0,31 |

| 163 25x33 | 25 | 1” | 33.0 | 4 | 10 | 30 | 250 | 0,43 |

Possible end-fittings : Threaded

See also 162, 164

| 164 |

| |

The hose 164 is intended for hot water connections for thermal engine cooling systems.

Its double metal spiral gives it a small bend radius.

Its external appearance is described by the term 'flat corrugated'.

Its inner tube is resistant to glycol and glycol solutions.

Since it is made entirely of EPDM, it can be used for many suction and discharge applications for a wide variety of fluids, such as seawater or acid solutions.

It is available on stock in many diameters.

Technical specifications:

Inner tube : smooth EPDM rubber

Reinforcement : 4 textile plies, 2 metal spiral

Outer cover : Flat corrugated EPDM rubber

Outer finish : wrapped

Temperature : - 40°C to 125° C

Production lengths : 40 or 60 meters

Colour : black

Marking : TECALEMIT - PART N° - HOT WATER - 10 BAR - BATCH N°

| Part n° | Inner diameter | Outer diameter | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | bar | bar | mm | g/m | |

| 164 19 | 19 | 3/4” | 27 | 10 | 30 | 50 | 0,45 |

| 164 25 | 25,4 | 1” | 34 | 10 | 30 | 65 | 0,60 |

| 164 40 | 40 | 50 | 10 | 30 | 90 | 0,90 | |

| 164 50 | 50 | 2” | 62 | 10 | 30 | 120 | 1,50 |

| 164 60 | 60 | 70 | 10 | 30 | 150 | 1,70 | |

| 164 63 | 63 | 2” 1/2 | 74 | 10 | 30 | 160 | 1,75 |

| 164 76 | 76 | 3” | 88 | 10 | 30 | 200 | 2,30 |

| 164 80 | 80 | 93 | 10 | 30 | 220 | 2,70 | |

| 164 85 | 85 | 99 | 10 | 30 | 230 | 2,85 | |

| 164 90 | 90 | 105 | 10 | 30 | 250 | 3,20 | |

| 164102 | 102 | 4” | 117 | 10 | 30 | 280 | 3,70 |

| 164114 | 114 | 129 | 10 | 30 | 310 | 4,20 | |

| 164120 | 120 | 136 | 10 | 30 | 340 | 5,10 | |

| 164127 | 127 | 5” | 143 | 10 | 30 | 350 | 5,70 |

| 164139 | 139 | 157 | 10 | 30 | 460 | 6,40 | |

| 164150 | 152,4 | 6” | 169 | 10 | 30 | 580 | 7,30 |

| 164168 | 168 | 188 | 10 | 30 | 700 | 10,00 | |

| 164200 | 203 | 225 | 10 | 30 | 900 | 14,50 | |

Possible end-fittings : Threaded, Flanges, Victaulic, specials

| Ref 166 |

| |

La manguera 166 está destinada a la succión y el suministro de agua caliente incluso con un aditivo de baja concentración.

Su revestimiento plano de caucho EPDM corrugado es resistente a la abrasión, al calor, al ozono y a los agentes atmosféricos.

Características técnicas:

Tubo interno: caucho EPDM liso

Refuerzo: capa textil de alta tenacidad, espiral metálica

Revestimiento: caucho EPDM acanalado

Apariencia: tela, acanalado

Temperatura: -40 °C a 125 °C

Longitud de fabricación: 40, 46 o 61 metros

Color: negro

Marcado: Ref 166 - eau chaude - bars - lote

| Referencia | Diámetro interior | Diámetro exterior | Depresión | Presión de servicio | Presión L.N.E | Radio de curvatura | Peso | |

| mm | Pulgada | mm | bar | bar | bar | mm | kg/m | |

| 166 19 | 19 | 3/4" | 29 | -0,92 | 10 | 30 | 40 | 0,50 |

| 166 22 | 22 | 7/8" | 32 | -0,92 | 10 | 30 | 45 | 0,57 |

| 166 25 | 25,4 | 1" | 35 | -0,92 | 10 | 30 | 50 | 0,61 |

| 166 28 | 28 | 1"1/8 | 38 | -0,92 | 10 | 30 | 55 | 0,73 |

| 166 32 | 32 | 1"1/4 | 42 | -0,92 | 10 | 30 | 65 | 0,81 |

| 166 38 | 38 | 1"1/2 | 48 | -0,92 | 10 | 30 | 85 | 1,10 |

| 166 50 | 50,8 | 2" | 62 | -0,92 | 10 | 30 | 120 | 1,13 |

| 166 65 | 63,5 | 2"1/2 | 75 | -0,92 | 10 | 30 | 160 | 1,78 |

| 166 75 | 76,2 | 3" | 90 | -0,92 | 8 | 24 | 190 | 2,55 |

| 166 100 | 101,6 | 4" | 117 | -0,92 | 8 | 24 | 280 | 3,92 |

| 166 127 | 127 | 5" | 146 | -0,92 | 8 | 24 | 350 | 6,04 |

| 166 150 | 152,4 | 6" | 170 | -0,92 | 8 | 24 | 550 | 6,67 |

| 167 |

| |

The hose 167 is intended for cooling water circuits on thermal engines.

Its inner tube is resistant to glycolated water and diluted acids.

Cut in lengths of 1 meter to manufacture.

It is extremely flexible and light, its outer cover is corrugated.

Caractéristiques techniques:

Inner tube : smooth EPDM rubber

Reinforcement : textile plies, metal spiral

Outer cover : EPDM rubber

Outer finish : wrapped and corrugated

Temperature : - 30°C to 120°C

Production lengths : 1 meter

Colour : black

Marking : TECALEMIT - PART N° - HOT WATER - 4 BAR - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 167 22x30 | 22 | 7/8” | 30 | 4,0 | 4 | 12 | 50 | 0,4 |

| 167 25x34 | 25,4 | 1” | 34 | 4,5 | 4 | 12 | 60 | 0,45 |

| 167 28x36 | 28,5 | 1” 1/8 | 36 | 4,0 | 4 | 12 | 65 | 0,5 |

| 167 30x38 | 30 | 1” 3/16 | 38 | 4,0 | 4 | 12 | 70 | 0,55 |

| 167 32x41 | 31,8 | 1” 1/4 | 41 | 4,5 | 4 | 12 | 70 | 0,6 |

| 167 35x45 | 35 | 1” 3/8 | 45 | 5,0 | 4 | 12 | 75 | 0,65 |

| 167 38x47 | 38,1 | 1” 1/2 | 47 | 4,5 | 4 | 12 | 80 | 0,7 |

| 167 40x49 | 40 | 1” 9/16 | 49 | 4,5 | 4 | 12 | 80 | 0,75 |

| 167 42x52 | 42 | 1” 21/32 | 52 | 5,0 | 4 | 12 | 85 | 0,8 |

| 167 45x55 | 45 | 1” 3/4 | 55 | 5,0 | 4 | 12 | 90 | 0,9 |

| 167 48x58 | 48 | 1”7/8 | 58 | 5,0 | 4 | 12 | 100 | 0,95 |

| 167 51x61 | 50,8 | 2” | 61 | 5,0 | 4 | 12 | 110 | 1 |

| 167 57x67 | 57,1 | 2”1/4 | 67 | 5,0 | 4 | 12 | 120 | 1,2 |

| 167 60x70 | 60 | 2”3/8 | 70 | 5,0 | 4 | 12 | 130 | 1,3 |

| 167 63x73 | 63,5 | 2”1/2 | 73 | 5,0 | 4 | 12 | 140 | 1,4 |

| 167 70x80 | 70 | 2”3/4 | 80 | 5,0 | 4 | 12 | 150 | 1,6 |

| 167 76x86 | 76,2 | 3” | 86 | 5,0 | 4 | 12 | 150 | 1,8 |

| 167 102x112 | 101,6 | 4” | 112 | 5,0 | 4 | 12 | 200 | 2,1 |

Possible end-fittings : Threaded

| 191 |

| |

This textile reinforced hose, used for hydrodynamically cleaning sewers or industrial sites, has great weight advantage over metal braid hoses.

This structure also increases safety of users.

The outer cover is comprised of an extremely abrasion resistant rubber (also used for sand blasting) greatly increasing life of the hose.

Technical specifications:

Inner tube : black SBR rubber

Reinforcement : 2 textile braids

Outer cover : abrasion resistant SBR / NR rubber

Outer finish : smooth

Temperature : - 40°C to +90° C

Production lengths : between 80 and 120 meters maximum

Colour : black

Marking : TECALEMIT - PART N° - 250 BAR - Ø - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 191 19 | 19 | 3/4” | 31,6 | 6,5 | 250 | 625 | 90 | 0,55 |

| 191 25 | 25 | 1” | 39,3 | 7 | 250 | 625 | 105 | 0,78 |

Possible end-fittings : Threaded

| 321B | |

| NF EN 853 | |

Produced on flexible mandrils, this hose is vulcanised on reels.

In diameter 25, hose part N° 993 68 05 is made for this application, with a thick cover.

Hose assemblies equipped with either swaged or reusable end-fittings can be supplied with a test certificate.

Technical specifications:

Inner tube : black nitrile rubber

Reinforcement : 1 or 2 metal braids

Outer cover : abrasion and weather resistant neoprene rubber

Outer finish : wrapped

Temperature : - 40°C to +90°C

Production lengths : 240 meters max.

Colour : black

Marking : TECALEMIT - PART N° - STANDARD - Ø - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 93 45 03 | 13 | 1/2" | 21,4 | 4,5 | 203 | 640 | 178 | 0.34 |

| 93 95 09 | 13 | 1/2" | 23,0 | 5,1 | 349 | 1100 | 178 | 0.62 |

| 93 36 02 | 19 | 3/4" | 28,5 | 4,8 | 133 | 420 | 240 | 0.64 |

| 93 77 09 | 19 | 3/4" | 30,1 | 5,6 | 269 | 850 | 240 | 0.98 |

| 93 68 09 | 25 | 1” | 38,9 | 6,8 | 206 | 650 | 300 | 1,38 |

| 93 68 40 | 25 | 1” | 36 | 5,3 | 209 | 650 | 250 | 1,22 |

Possible end-fittings : S type

| 567 |

| |

Intended for high pressure cleaning at 400 bar, this hose is available with two different microperforated outer covers : a very robust black one and a blue one which does not mark floors.

In both cases, the outer cover resists animal fats and a wide range of detergents and its thickness ensures good resistance to wear.

Technical specifications:

Inner tube : high temperature black nitrile rubber

Reinforcement : 2 metal braids

Outer cover : abrasion resistant neoprene rubber

Outer finish : wrapped

Temperature : -30°C to +120°C, intermittent 150°C

Production lengths : variable

Colour : black or blue

Marking : TECALEMIT - PART N° - LAVAGE 400 BAR - Ø - BATCH N°

| Part n° | Inner diameter | Outer diameter | working pressure | Test pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 567 6 B | 6,4 | 1/4" | 15,7 | 12,7 | 400 | 1600 | 102 | 0.37 |

| 567 8 B | 7,9 | 5/16" | 17,3 | 14,3 | 400 | 1600 | 114 | 0.45 |

| 567 10 B | 10 | 3/8" | 19,7 | 16,7 | 400 | 1600 | 127 | 0.57 |

| 567 13 B | 12,7 | 1/2" | 23,1 | 19,8 | 400 | 1600 | 178 | 0.65 |

| 567 8 N | 7,9 | 5/16" | 17,3 | 14,3 | 400 | 1600 | 114 | 0,45 |

| 567 10 N | 10 | 3/8" | 19,7 | 16,7 | 400 | 1600 | 127 | 0,57 |

Possible end-fittings : hydraulics end-fittings

See also 513

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR