Civil security delivery rubber hoses

| Aspiral | ||

|  N° : 111.TA.06 | NF EN ISO 14557 | |

This very robust hose is swaged with half-symetrical guillemin fittings in diameters 40 and 70, and with AR fittings in diameter 100 in order to obtain hose assemblies for civil protection equipment.

These are in accordance with NFS 61113 and the new NF EN ISO 14557 standard.

The conformity of these products with the ISO 14557 standard is guranteed by AFNOR Certification who have authorised the NF logo on these hoses.

Technical specifications :

Inner tube : smooth SBR rubber

Reinforcement : 4 textile plies and metal spiral

Outer cover : abrasion and weather resistant SBR rubber

Admissible negative pressure : 0.9 bars

Outer finish : wrapped

Temperature : 90°C max

Production lengths : 2 meters

Colour : black

Embossed marking : According to the norm

White layline marking : According to the norm

| Part n° | Inner diameter | Outer diameter | Wall thickness | Working pressure | Burst pressure | Bend radius | Total Weight | |

| mm | Inch | mm | mm | bar | bar | mm | ||

| ASPIRAL DN 40 | 45 | 1"3/4” | 55 | 5 | 6 | 17 | 320 | 1,2 |

| ASPIRAL DN 60 | 70 | 2” 3/4 | 82 | 6 | 6 | 17 | 570 | 2,8 |

| ASPIRAL DN 100 | 110 | 4"11/32 | 124 | 7 | 6 | 17 | 800 | 4,5 |

Possible end-fittings : half-symetrical guillemin fitting dia. 40 & 65 & ar setting dia. 100

| 114 | ||

|  N° : 111.TSR.06 |  NF EN 1947 | |

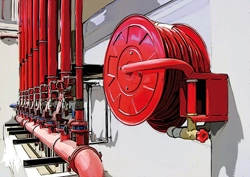

Hose114 is used on fire department hose reels for delivery of water at 40 bars.

This hose has been approved by the French interior ministry for use by civil protection services.

This hose conforms to NF EN 1947 class 1 standards (its inner tube and outer cover are in rubber) category 2 and type C (wp 40 bars and minimum burst pressure 120 bars) : it is therefore a high quality hose.

Compared with the red PVC hose which is usually found on booster lines, this hose has many advantages : same flexibility during high summer temperatures or during the winter colds, same working pressure at 20°C or 90°C, better fire-resistance, bend radius and resistance to deformation.

It has less “reel-shape memory”, which facilitates use in stairways during interventions on fires in garbage chutes.

Technical specifications :

Inner tube : black SBR rubber

Reinforcement : textile plies

Outer cover : black CR abrasion resistant rubber

Outer finish : fine tape-wrapped

Temperature : 0°C to 90°C

Production lengths : 60 meters

Colour : black

Embossed marking : According to the norm

Marking on white lay line : According to the norm

| Part n° | Inner diameter | Outer diameter | Wall thickness | Working pressure | Pression L.N.E | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 114 25 | 25,4 | 1” | 36 | 5,5 | 40 | 120 | 90 | 0,70 |

Possible end-fittings : GFR, threaded

| 995/996 | ||

|  N° : 111.TSR.07 | NF EN 1947 + A1 | |

The semi-rigid (TSR) hoses REF 995 25 and REF 996 25 are used for fire fighting application in fire reels.

These are in accordance with NF EN 1947 + A1 classe 2 standard.

Hose 995 25 is Class 1 and hose 996 25 is Class 2.

Technical specifications :

Inner tube : black PVC

Reinforcement : 1 textile braid

Outer cover : PVC, flame resistant

Outer finish : smooth

Temperature : -20°C to + 60°C

Production lengths : 20, 30, 40 meters

Colour : red or black on request

Marking 995 : According to the norm

Marking 996 : According to the norm

| Part n° | Inner diameter | Outer diameter | Wall thickness | Working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 995 25 | 25 | 1” | 34 | 4,3 | 15 | 45 | 120 | 0,56 |

| 996 25 | 25 | 1” | 35,5 | 5,2 | 40 | 100 | 120 | 0,75 |

Possible end-fittings : threaded, GFR, Half-symetrical guillemin

| 997 | |

| NF EN 694 + A1 | |

The hose 997 are intended for RIA equipment (fire taps reinforced) and PIA (fire stations additive) found in some place of public assembly.

These are in accordance NF EN694 + A1 (NFS 61 115) type A classe 2 standard.

Technical specifications :

Inner tube : black PVC

Reinforcement : 1 textile braid

Outer cover : PVC, flame resistant

Outer finish : smooth

Temperature : -20°C to + 60°C

Production lengths : 20 meters

Colour : red

Marking : TECALEMIT - EN 694 : 2001 - A - 2 - Ø - MPA & BAR PRESSURE - TRIMESTER/YEAR - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | Working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 997 19 | 19 | 3/4” | 26 | 3,5 | 12 | 42 | 230 | 0,385 |

| 997 25 | 25 | 1” | 33 | 4 | 12 | 42 | 300 | 0,565 |

| 997 33 | 33 | 43 | 5 | 7 | 25 | 385 | 0,910 | |

Possible end-fittings : threaded, GFR, Half-symetrical guillemin

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR