Air & gas delivery rubber hoses

| 201 | |

| NF EN ISO 2398 | |

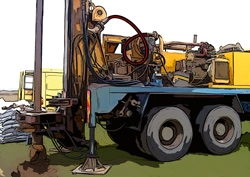

The hose 201 is used for compressed air at high pressures.

It has characteristics superior to the international standard ISO 2398 type 3 (high pressure), class C (resistant to oil), NT (normal temperature).

Its nitrile inner tube is resistant to compressor oil. its outer cover is resistant to abrasion.

Its metal wire spirals give good flexibility.

It can be found in mining and public works.

It can be equipped with swaged fittings and also anti-whip cables or safety stockings.

Technical specifications :

Inner tube : smooth oil resistant NBR rubber

Reinforcement : 2 or 4 metal spirals

Outer cover : abrasion and weather resistant neoprene rubber

Outer finish : fine tape wrapped

Temperature - 40°C to + 70° C

Production lengths : 60 meters

Colour : black

Marking : TECALEMIT - PART N° - EXCEED ISO 2398 3/C/NT - BATCH N° - MICROPERFORATED

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 201 13 | 12,7 | 1/2" | 23 | 5 | 40 | 160 | 180 | 0,6 |

| 201 16 | 15,9 | 5/8" | 27 | 5,5 | 40 | 160 | 200 | 0,8 |

| 201 19 | 19 | 3/4" | 31 | 6 | 40 | 160 | 220 | 0,9 |

| 201 25 | 25,4 | 1" | 39 | 7 | 40 | 160 | 250 | 1,1 |

| 201 32 | 31,8 | 1"1/4 | 46 | 7 | 40 | 160 | 300 | 1,6 |

| 201 38 | 38,1 | 1"1/2 | 53 | 7,5 | 40 | 160 | 350 | 1,9 |

| 201 50 | 50,8 | 2" | 68 | 9 | 40 | 160 | 450 | 2,8 |

| 201 60 | 60 | 2" 3/8 | 77 | 8,5 | 40 | 160 | 300 | 3,2 |

| 201 75 | 76,2 | 3" | 95 | 9 | 40 | 160 | 650 | 4,3 |

| 201 100 | 101,6 | 4" | 120 | 9 | 40 | 160 | 900 | 5,9 |

Possible end-fittings : Male threaded, female BSP, robur, weco, flangee

See also 223, 224

| 202 |

| |

The 202 hose is intended for snow cannons.

It has an excellent bend radius and resists shock and mechanical stress thanks to its two metal braids.

Its SBR / EPDM rubber outer cover ensures excellent resistance to abrasion, ozone and atmospheric agents.

Technical specifications :

Inner tube : SBR/EPDM rubber

Reinforcement : 2 metal braids

Outer cover : SBR/EPDM rubber

Outer finish : smooth

Temperature : -40°C to +80° C

Production lengths : 40 meters

Colour : blue

Marking : Tecalemit Flexibles - Part N° - ø - ps/wp - batch N°

| Part n° | Inner diameter | Reinforcement outer diameter | Outer diameter | Negative pressure | Working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | bar | mm | kg/m | |

| 202 25 | 25,4 | 1" | 34,9 | 38,1 | -0,8 | 50 | 160 | 300 | 1,47 |

| 202 38 | 38,1 | 1"1/2 | 50,8 | 54,6 | -0,8 | 50 | 160 | 500 | 2,51 |

| 202 50 | 50,8 | 2" | 63,5 | 67,6 | -0,8 | 50 | 160 | 630 | 3,19 |

| 203 | |

| ISO 2398 2-A-LT | |

As flexible in winter as in summer, compressed air hose 203 is used in workshops and particularly in garages.

Its electrically-conductive inner tube eliminates static electricity.

It can be produced in all diameters up to ID 19mm.

It conforms with ISO 2398 2-A-LT : medium pressure, non-oil resistant and low temperature.

Technical specifications :

Inner tube : electrically - conductive EPDM

Reinforcement : textile braid

Outer cover : EPDM

Outer finish : smooth

Temperature : -40° C to 70°C maximum

Production lengths : 20 and 40 meters

Colour : blue

Marking : TECALEMIT - PART N° - TUYAU AIR CONDUCTEUR/AIR CONDUCTIVE HOSE

NF ISO 2398 - 2A - Ø - PS/WP 2 MPA/16BAR/300PSI - DATE - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | Working pressure | Burst | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 203 6x12 | 6 | 1/4" | 12 | 3,0 | 16 | 64 | 30 | 0,13 |

| 203 8x15 | 8 | 5/16" | 15 | 3,5 | 16 | 64 | 35 | 0,16 |

| 203 10x17 | 10 | 3/8" | 17 | 3,5 | 16 | 64 | 550 | 0,23 |

Possible end-fittings : Express, coupling

See also Ref 222, Ref 234

| 207 | |

| UTAC ST 954-02 | |

This hose is used in replacement of polyamide 12 brake tubes according to DIN 74324 for repairs of road trailers.

It gives increased safety to braking systems.

Technical specifications :

Inner tube : SBR / NR

Reinforcement : textile braids

Outer cover : SBR EPDM rubber

Outer finish : smooth

Temperature : - 30°C to +70°C

Production lengths : variable

Colour : black

Marking : TECALEMIT - PART N°- UTAC ST 954 - 02 - Ø - BATCH N°

| Part n° | Diamètre intérieur | Outer diameter | Wall thickness | Working | Pression L.N.E | Bend radius | Weight |

| mm | mm | mm | bar | bar | mm | kg/m | |

| 207 8 | 8 | 18 | 5 | 10 | 65 | 70 | 0.30 |

| 207 10 | 10 | 18 | 4 | 10 | 65 | 80 | 0.24 |

| 207 13 | 13 | 22 | 4,5 | 10 | 65 | 120 | 0.34 |

Possible end-fittings : Threaded

See also : Tube PA12 DIN 74324

| Ref 212 / 213 | |

| EN ISO 3821 | |

212 Blue: Oxygen | ||

| ||

212 Rouge: Acétylène | ||

| ||

213 Orange: Propane | ||

These hoses comply with the international standards EN 559 and ISO 3821 in single duct version or in twin version.

They are light and manageable.

their safety coefficients are very high and their resistance to hot spots and to the flame are excellent.

Technical specifications :

Inner tube : NBR/SR

Reinforcement : synthetic yarns

Outer cover : abrasion and weather resistant synthetic rubber

Outer finish : smooth

Temperature : - 30°C to +80°C

Production lengths : 40 meters

OXYGEN:

Colour : blue

Marking : TECALEMIT OXYGENE - EN 559 - ISO 3821 - 2 MPA (20 BAR) - 10 - YEAR - BATCH N° DOUBLE PACKING

PROPANE:

Colour : orange

Marking : TECALEMIT PROPANE - EN 559 - ISO 3821 - 2 MPA (20 BAR) - 10 - YEAR - BATCH N° DOUBLE PACKING

ACETYLENE:

Colour : red

Marking : TECALEMIT ACETYLENE - EN 559 - ISO 3821 - 2 MPA (20 BAR) - 10 - YEAR - BATCH N° DOUBLE PACKING

212 B Oxygen

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 212 B 5 | 5 | 3/16" | 12 | 3,5 | 20 | 60 | 45 | 0.13 |

| 212 B 6 | 6 ,3 | 1/4" | 13 | 3,8 | 20 | 60 | 60 | 0.14 |

| 212 B 8 | 8 | 5/16" | 15 | 3,5 | 20 | 60 | 75 | 0.17 |

| 212 B 10 | 10 | 3/8" | 17 | 3.5 | 20 | 60 | 90 | 0.21 |

| 212 B 12 | 12 | 1/2" | 22 | 4,7 | 20 | 60 | 110 | 0.34 |

212 R Acetylene

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 212 R 5 | 5 | 3/16" | 12 | 3,5 | 20 | 60 | 45 | 0.13 |

| 212 R 6 | 6 ,3 | 1/4" | 13 | 3,8 | 20 | 60 | 60 | 0.14 |

| 212 R 8 | 8 | 5/16" | 15 | 3,5 | 20 | 60 | 75 | 0.17 |

| 212 R 10 | 10 | 3/8" | 17 | 3.5 | 20 | 60 | 90 | 0.21 |

| 212 R 12 | 12 | 1/2" | 22 | 4,7 | 20 | 60 | 110 | 0.34 |

213 Propane

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 213 6 | 6 ,3 | 1/4" | 13 | 3,8 | 20 | 60 | 60 | 0.14 |

| 213 8 | 8 | 5/16" | 15 | 3,5 | 20 | 60 | 75 | 0.17 |

| 213 10 | 10 | 3/8" | 17 | 3.5 | 20 | 60 | 90 | 0.21 |

Possible end-fittings : Threaded, coupling

| 222 | |

| NF EN ISO 2398 - 1B | |

Compressed air hose 222 is used in workshops.

Hose 222 has characteristics above 2398 Type 1 (operating pressure 10 bar), Class B (resistant to compressor oils), and category NT (for normal temperature).

It is also chosen for air supply of jackhammers on worksites for its competitiveness.

It can be produced in any inner diameter up to 25mm.

Technical specifications :

Inner tube : smooth SBR / NBR rubber

Reinforcement : textile braid

Outer cover : SBR rubber

Outer finish : smooth

Temperature : - 30°C to +70°C maximum

Production lengths : 40 meters, possibility of 100 meters

Colour : black or other

Marking : TECALEMIT - PART N° - TUYAU AIR/AIR HOSE - NF EN ISO 2398 - 1B - 19mm/3/4"- WP/PS 15BARS/210 PSI - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 222 5x11 | 5 | - | 11 | 2.8 | 15 | 45 | 25 | 0.11 |

| 222 6x12 | 6 | - | 12 | 3.0 | 15 | 45 | 30 | 0.13 |

| 222 7x13 | 7 | - | 13 | 3.0 | 15 | 45 | 32 | 0.14 |

| 222 8x15 | 8 | - | 15 | 3.5 | 15 | 45 | 35 | 0.16 |

| 222 9x16 | 9 | - | 16 | 3.5 | 15 | 45 | 40 | 0.22 |

| 222 10x17 | 10 | - | 17 | 3.5 | 15 | 45 | 50 | 0.23 |

| 222 13x19 | 13 | - | 19 | 3,5 | 15 | 45 | 65 | 0.35 |

| 222 13X23 | 13 | - | 23 | 5.0 | 15 | 45 | 65 | 0.35 |

| 222 16x26 | 16 | - | 26 | 5.0 | 15 | 45 | 80 | 0.51 |

| 222 19x29 | 19 | - | 29 | 5.0 | 15 | 45 | 100 | 0.60 |

| 222 25x32 | 25 | - | 36 | 5.5 | 15 | 45 | 150 | 0.80 |

Possible end-fittings : Express, coupling

See also 221, 234

| 223 |

| |

Hose 223 has characteristics above Standard 2398 Type 1 (operating pressure 10 bar), Class B (resistant to compressor oils), and Category NT (for normal temperature)

Its inner tube is resistant to compressor oil.

its outer cover is abrasion resistant.

Its life span and inter-layer are excellent.

Produced from diameter 30mm upwards, it can be found on high rate air compressors.

Technical specifications :

Inner tube : SBR / NBR rubber

Reinforcement : textile plies

Outer cover : abrasion and weather resistant SBR rubber

Outer finish : fine tape wrapped

Temperature : - 30°C to +70°C

Production lengths : 40, 60 meters

Colour : black

Marking : TECALEMIT - PART N° - AIR COMPRIMÉ 15 BAR - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 223 30x42 | 30 | 1” 3/16 | 42 | 6.0 | 15 | 50 | 210 | 0,8 |

| 223 35x46 | 35 | 1” 3/8 | 47 | 6.0 | 15 | 50 | 250 | 0,9 |

| 223 40x53 | 40 | 1” 9/16 | 53 | 6.0 | 15 | 50 | 300 | 1,5 |

| 223 40x58 | 40 | 1” 9/16 | 58 | 9.0 | 15 | 50 | 300 | 1,5 |

| 223 45x57 | 45 | 1” 3/4 | 57 | 6.0 | 15 | 50 | 350 | 1,6 |

| 223 50x65 | 50,8 | 2” | 65 | 7.0 | 15 | 50 | 400 | 1,72 |

| 223 60x76 | 60 | 2” 3/8 | 76 | 8.0 | 15 | 50 | 500 | 2,4 |

| 223 63x79 | 63,5 | 2” 1/2 | 78 | 7.5 | 15 | 50 | 530 | 2,1 |

| 223 70x85 | 70 | 2” 3/4 | 85 | 7.5 | 15 | 50 | 580 | 2,54 |

| 223 76x90 | 76,2 | 3” | 90 | 7.0 | 15 | 50 | 620 | 3,2 |

| 223 80x95 | 80 | 3” 5/32 | 95 | 8.0 | 15 | 50 | 660 | 3,4 |

| 223 90x104 | 90 | 3” 1/2 | 104 | 8.0 | 15 | 50 | 750 | 3,8 |

| 223 102x118 | 101,6 | 4” | 118 | 8.0 | 15 | 50 | 1000 | 3,77 |

| 223 110x126 | 110 | 4" 11/32 | 126 | 8.0 | 15 | 50 | 1080 | 4,5 |

| 223 152x173 | 152,4 | 6” 3/16 | 173 | 9.0 | 15 | 45 | 1520 | 7,48 |

Possible end-fittings : male BSP taper, robur, cam-lock, weco

See also 224

| 224 | |

|

| |

Hose 224 is without doubt one of the toughest hoses on the market.

Its inner tube is resistant to compressor oil and its outer cover is abrasion resistant.

It has an excellent life span.

Moreover, its heavy textile reinforcement and its superior thickness increase its mechanical resistance to traction, flexion and other constraints.

Technical specifications :

Inner tube : oil resistant SBR/NBR rubber

Reinforcement : textile plies

Outer cover : abrasion and weather resistant SBR rubber

Outer finish : fine tape wrapped

Temperature : -30° C to +70° C max

Production lengths : 60 meters

Colour : black

Marking : TECALEMIT - PART N° - AIR COMPRIMÉ 20 BAR - DATE / BATCH N°s

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 224 13x21 | 13 | 1/2" | 21 | 4 | 20 | 64 | 65 | 0,4 |

| 224 16x27 | 16 | 5/8” | 27 | 5.5 | 20 | 64 | 160 | 0,5 |

| 224 19x32 | 19 | 3/4” | 32 | 6.5 | 20 | 64 | 190 | 0,73 |

| 224 25x38 | 25,4 | 1” | 39 | 6.5 | 20 | 64 | 254 | 0,96 |

| 224 28x44 | 28 | 1” 1/8 | 44 | 8 | 20 | 64 | 180 | 1,1 |

| 224 30x44 | 30 | 1”3/16 | 44 | 7.0 | 20 | 64 | 300 | 1,23 |

| 224 35x50 | 35 | 1”3/8 | 50 | 7.5 | 20 | 64 | 350 | 1,36 |

| 224 40x56 | 40 | 1”9/16 | 56 | 8.0 | 20 | 64 | 400 | 1,9 |

| 224 45x61 | 45 | 1”3/4 | 61 | 8.0 | 20 | 64 | 450 | 2,0 |

| 224 50x70 | 50,8 | 2” | 68 | 9.0 | 20 | 64 | 508 | 2,3 |

| 224 60x78 | 60 | 2”3/8 | 78 | 9.0 | 20 | 64 | 600 | 2,7 |

| 224 63x81 | 63,5 | 2”1/2 | 81 | 9.0 | 20 | 64 | 635 | 2,9 |

| 224 70x88 | 70 | 2”3/4 | 88 | 9.0 | 20 | 64 | 700 | 3,2 |

| 224 75x96 | 76 | 3” | 96 | 10.0 | 20 | 64 | 760 | 3,7 |

Possible end-fittings : male threaded, Robur, Cam-lock, Weco

See also 223, 2011

| 234 | |

| ||

Hose REF 234 is extruded.

It is used on worksites for air supply of air tools.

It can be produced in any inner diameter up to 25mm with various thicknesses.

Technical specifications :

Inner tube : EPDM rubber

Reinforcement : textile plies

Outer cover : EPDM rubber

Outer finish : smooth

Temperature : - 30°C to +70°C

Production lengths : 40 meters

Colour : black with blue stripes

Marking : TECALEMIT - PART N° - TUYAU AIR/AIR HOSE - Ø - WORKING PRESSURE - BATCH N

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 234 5x11 | 5 | 11 | 3.0 | 20 | 64 | 25 | 0.10 | |

| 234 6x14 | 6 | 14 | 4.0 | 20 | 64 | 30 | 0.17 | |

| 234 7x16 | 7 | 16 | 4.5 | 20 | 64 | 35 | 0.20 | |

| 234 9x17 | 9 | 17 | 4.0 | 20 | 64 | 40 | 0.22 | |

| 234 10x18 | 10 | 18 | 4.0 | 20 | 64 | 50 | 0.24 | |

| 234 13x23 | 13 | 23 | 5.0 | 20 | 64 | 60 | 0.30 | |

| 234 16x26 | 16 | 26 | 5.0 | 20 | 64 | 80 | 0.46 | |

| 234 19x30 | 19 | 30 | 5.5 | 20 | 64 | 100 | 0.59 | |

| 234 25x37 | 25 | 37 | 6 | 20 | 64 | 130 | 0.9 | |

Possible end-fittings : Express, coupling

See also Ref 221, Ref 222

| 254 |

| |

Hose 254 is used for many fluids down to -54 ° C in continuous service.

Originally designed for low temperature air and nitrogen service application, it can likewise be used for many other fluids such as water, mineral oils and gas-oil and thus be considered a multiservice hose.

With great flexibility, it can be equipped with swaged fittings and also anti-whip cables or safety stockings.

Technical specifications :

Inner tube : black smooth oil, air, and gaz special resistant rubber designed for low temperatures

Reinforcement : 2 high tensile synthetic textile layers

Outer cover : black abrasion and weather special resistant rubber to low temperatures

Outer finish : fine tape wrapped

Temperature - 54°C to + 70° C

Colour : black

Production lengths : 61 meters

Marking : TECALEMIT - PART N° - AIR / WATER / NITROGEN SPECIAL HOSE LOW TEMPERATURE -54°C

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 254 19x31 | 19 | 3/4” | 31 | 6.0 | 20 | 60 | 190 | 0.58 |

| 254 25x37 | 25 | 1” | 37 | 6.0 | 20 | 60 | 190 | 0.73 |

| 277 |

| |

Although extremely lightweight, hose REF 277 can accept high working pressures.

It is used for light compressed air service or wherever its weight and compact dimensions are the determinating factors.

Its outer cover and inner tube are produced with one single induction which interpenetrates the braiding, rendering ideal adherence between the layers.

The proportion of elastomer nitrile-pvc is 70/30%.

It benefits from the NSFS 61 112 approval for diameters 25, 45, 70 and 110.

Diameter 51, for severe applications, this hose is available with a greater thickness. It therefore has better abrasion resistance.

art N° 279 50 and Part N° 280 50 with an operation pressure of 25 bars.

Technical specifications :

Inner tube : elastomer NBR - PVC

Reinforcement : textile braid

Outer cover : abrasion and weather resistant nitrile - PVC

Outer finish : smooth with longitudinal ribs

Temperature : - 20°C to 70°C maximum

Production lengths : 20 and 40 meters, up to 200 meters to order

Colour : black for dia. 20, 25, 50, 75, 100 and 150

Marking : none

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 277 20 | 20 | 24.0 | 2.0 | 25 | 80 | - | 0.16 | |

| 277 25 | 25 | 1” | 29.0 | 2.0 | 25 | 75 | - | 0.18 |

| 277 38 | 39 | 1”1/2 | 40.5 | 2.2 | 18 | 55 | - | 0.28 |

| 277 40 | 40 | 1”9/16 | 44.5 | 2.2 | 18 | 55 | - | 0.30 |

| 277 42 | 42 | 1”21/32 | 46.5 | 2.2 | 18 | 50 | - | 0.34 |

| 277 45 | 45 | 1”3/4 | 49.5 | 2.3 | 18 | 50 | - | 0.37 |

| 277 50 | 52 | 2” | 55.0 | 2.3 | 18 | 50 | - | 0.44 |

| 279 50 | 52 | 2” | 59 | 3.5 | 18 | 60 | - | 0.65 |

| 280 50 | 52 | 2” | 59 | 3.5 | 25 | 90 | - | 0.65 |

| 277 55 | 55 | 60.0 | 2.4 | 18 | 50 | - | 0.47 | |

| 277 60 | 60 | 2”3/8 | 65.0 | 2.4 | 18 | 50 | - | 0.51 |

| 277 65 | 64 | 2”1/2 | 68.5 | 2.5 | 18 | 50 | - | 0.53 |

| 277 70 | 70 | 2”3/4 | 75.0 | 2.5 | 18 | 50 | - | 0.60 |

| 277 75 | 75 | 3” | 81.0 | 2.5 | 18 | 50 | - | 0.70 |

| 277 80 | 80 | 85.5 | 2.7 | 18 | 50 | - | 0.77 | |

| 277 90 | 90 | 3”1/2 | 95.5 | 2.8 | 18 | 50 | - | 0.95 |

| 277 100 | 102 | 4” | 107.5 | 3.0 | 15 | 45 | - | 1.05 |

| 277 110 | 110 | 4”11/32 | 116.0 | 3.0 | 15 | 45 | - | 1.20 |

| 277 125 | 127 | 5” | 133.0 | 3.2 | 10 | 30 | - | 1.42 |

| 277 150 | 152 | 6” | 158.0 | 3.2 | 10 | 30 | - | 1.71 |

Possible end-fittings : Guillemin, Robur, Cam-lock

See also 223

| 522 |

| |

Hose type REF 299 is intended to convey hot compressed air exempt of oil.

It has excellent bend radius and resists shocks and mechanical strains.

It gives excellent results particularly in conveying pulverulents, for the compressed air connection between tank and tractor

Technical specifications :

Inner tube : black EPDM rubber

Reinforcement : metal spirals

Outer cover : black EPDM rubber

Outer finish : fine tape wrapped

Temperature : -50°C to +208°C

Production lengths : 61 meters

Colour : black with red stripe

Marking : Part N° - TECALEMIT - batch N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 522 55x71 | 55 | 2”1/8 | 71 | 8 | 20 | 175 | 230 | 2,3 |

| 522 65x81 | 63 | 80 | 8 | 20 | 175 | 300 | 2,64 | |

| 522 76x93 | 76 | 3” | 93 | 8,5 | 20 | 175 | 310 | 5,3 |

| 522 90x106 | 90 | 3”1/2 | 106 | 8 | 20 | 175 | 450 | 3,48 |

Possible end-fittings : Guillemin, Storz, threaded

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR