Abrasive delivery rubber hoses

| 618 |

| |

The polyurethane sheath 618 is remarkable by its lightweight and excellent bend radius.

The high abrasion-resistance rating of polyurethane allows the combination of light weight, flexibility and long life span of the hose.

It can be produced with wall thicknesses up to 1.8 mm.

Technical specifications :

Constitution : translucid polyurethane

Reinforcement : coppered steel spiral

Temperature : -25°C to +75°C

Production lengths : 10 to 30 metres

Colour : translucid

Marking : TECALEMIT - PART N° - PU/DIAMETER

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 618 30 | 30 | 1” 3/16 | - | 0.5 | 0.60 | - | 21 | 0.171 |

| 618 35 | 35 | 1” 3/8 | - | 0.5 | 0.55 | - | 24 | 0.199 |

| 618 40 | 40 | 1” 9/16 | - | 0.5 | 0.50 | - | 28 | 0.228 |

| 618 45 | 45 | 1” 3/4 | - | 0.5 | 0.45 | - | 31 | 0.261 |

| 618 50 | 50 | 2” | - | 0.5 | 0.40 | - | 35 | 0.295 |

| 618 55 | 55 | 2”1/4 | - | 0.5 | 0.40 | - | 39 | 0.318 |

| 618 60 | 60 | 2”3/8 | - | 0.5 | 0.40 | - | 42 | 0.342 |

| 618 65 | 65 | 2”1/2 | - | 0.5 | 0.37 | - | 45 | 0.370 |

| 618 70 | 70 | 2”3/4 | - | 0.5 | 0.35 | - | 49 | 0.399 |

| 618 75 | 75 | 3” | - | 0.5 | 0.30 | - | 53 | 0.427 |

| 618 80 | 80 | 3”5/32 | - | 0.5 | 0.27 | - | 56 | 0.456 |

| 618 90 | 90 | 3”9/16 | - | 0.5 | 0.25 | - | 58 | 0.486 |

| 618 100 | 100 | 4” | - | 0.5 | 0.20 | - | 70 | 0.515 |

| 618 110 | 110 | 4”11/32 | - | 0.5 | 0.20 | - | 77 | 0.566 |

| 618 120 | 120 | 4”23/32 | - | 0.5 | 0.20 | - | 84 | 0.618 |

| 618 125 | 125 | 5” | - | 0.5 | 0.20 | - | 88 | 0.644 |

| 618 130 | 130 | 5” 3/16 | - | 0.5 | 0.17 | - | 91 | 0.669 |

| 618 140 | 140 | 5” 1/2 | - | 0.5 | 0.13 | - | 98 | 0.720 |

| 618 150 | 150 | 6” | - | 0.5 | 0.10 | - | 105 | 0.772 |

| 618 160 | 160 | 6” 3/8 | - | 0.5 | 0.10 | - | 112 | 0.823 |

| 618 175 | 175 | 7” | - | 0.5 | 0.09 | - | 123 | 0.901 |

| 618 180 | 180 | 7” 3/8 | - | 0.5 | 0.09 | - | 127 | 0.925 |

| 618 200 | 200 | 8” | - | 0.5 | 0.08 | - | 140 | 1.024 |

| 618 250 | 250 | 10” | - | 0.5 | 0.05 | - | 175 | 1.280 |

| 618 300 | 300 | 12” | - | 0.5 | 0.03 | - | 210 | 1.540 |

| 618 350 | 350 | 14” | - | 0.6 | 0.02 | - | 245 | 1.792 |

| 618 400 | 400 | 16” | - | 0.6 | 0.02 | - | 280 | 2.048 |

| 618 450 | 450 | 18” | - | 0.6 | 0.01 | - | 315 | 2.304 |

| 618 500 | 500 | 20” | - | 0.6 | 0.01 | - | 350 | 2.560 |

| 701 |

| |

This hopper hose is used as a discharge spout for concrete on worksites.

Light and easy to handle, it allows user to easily pour the product.

Production of this hose on mandrils avoids having a longitudinal seam.

Technical specifications :

Inner tube : black anti-abrasive SBR rubber

Reinforcement : 2 textile plies

Outer cover : abrasion and weather resistant SBR rubber

Outer finish : wrapped

Temperature : - 30°C to +70°C

Production lengths : 20, 30 metres

Colour : black

Marking : none

Particularity : can be rolled flat

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 701 150 | 150 | 6” | 60 | 4 | 5 | 5 | - | 2.4 |

| 701 200 | 200 | 8” | 213 | 5 | 5 | 5 | - | 2.9 |

| 701 250 | 250 | 10” | 265 | 5.5 | 5 | 5 | - | 4.3 |

| 701 300 | 300 | 12” | 316 | 5.5 | 5 | 5 | - | 7.1 |

| 711 | |

| DIN 53416 | |

Hose 711 is intended for shotblasting metallic pieces, building fronts, ships, etc.

Its abrasion rating is under 60mm3 according to DIN 53416 standards.

It is appreciated by operators for 3 qualities :

- Its excellent dimensional stability during pressure variations

- Its constant external diameter allowing the mounting of fittings

- The electrical conductivity of its inner tube for safety and ease of fitting connections.

Technical specifications :

Inner tube : black electrically conductive anti-abrasive SBR rubber

Reinforcement : 2 textile plies

Outer cover : abrasion and weather resistant SBR rubber

Outer finish : wrapped

Temperature : - 30°C to +70°C

Production lengths : 20 metres except dias. 32x48, 50x70, 65x85 : 40 metres

Colour : black with yellow stripe

Particularity : additional micro-perforation of the outer cover

Marking : TECALEMIT - PART N° - ABRASIFS/SABLAGE - 12 BARS - PRODUCTION DATE OR BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 711 13x25 | 13 | 1/2” | 25.0 | 6.0 | 12 | 36 | 65 | 0,41 |

| 711 19x33 | 19 | 3/4” | 33.0 | 7.0 | 12 | 36 | 90 | 0,65 |

| 711 25x39 | 25,4 | 1” | 39.0 | 7.0 | 12 | 36 | 125 | 0,81 |

| 711 25x44 | 25,4 | 1” | 44.0 | 9.5 | 12 | 36 | 120 | 1,10 |

| 711 32x48 | 31,8 | 1” 1/4 | 48.0 | 8.0 | 12 | 36 | 160 | 1,16 |

| 711 32x52 | 31,8 | 1” 1/4 | 52.0 | 10.0 | 12 | 36 | 180 | 1,35 |

| 711 40x60 | 40 | 1” 9/16 | 60.0 | 10.0 | 12 | 36 | 260 | 1,60 |

| 711 50x70 | 50,8 | 2” | 70.0 | 10.0 | 12 | 36 | 320 | 2,10 |

| 711 60x80 | 60 | 2” 3/8 | 80.0 | 10.0 | 12 | 36 | 380 | 2,40 |

| 711 63x83 | 63,5 | 2” 1/2 | 83.0 | 10.0 | 12 | 36 | 400 | 2,60 |

| 711 65x85 | 65 | 85.0 | 10.0 | 12 | 36 | 400 | 2,60 | |

| 711 80x108 | 80 | 3” 5/32 | 108.0 | 14.0 | 12 | 36 | 460 | 4,60 |

| 711 90x118 | 90 | 3” 1/2 | 118.5 | 14.0 | 12 | 36 | 530 | 4,90 |

| 711 100x123 | 101,6 | 4” | 123.0 | 11.0 | 12 | 36 | 600 | 4,22 |

Possible end-fittings : specifics to sandblasting

See also 791, 798

| 731 |

| |

Hose 731 distinguishes itself by the anti-abrasion qualities of its inner tube.

The abrasion rating of 60mm 3 according to DIN 53516 is an excellent result.

In 7mm wall thickness, long life is due to its inner tube of 5mm thickness but also through its excellent “round-shape memory” avoiding kinking which increases the speed of abrasive products and outer wear by rubbing.

It can be equipped with Guillemin fittings swaged with aluminium or stainless steel ferrules.

Technical specifications :

Inner tube : black anti-abrasive SBR / NR rubber

Reinforcement : 2 textile plies

Outer cover : abrasion and weather resistant SBR rubber

Electrical conductivity : steel wire placed between textile plies

Outer finish : wrapped

Temperature : - 30°C to +70°C

Production lengths : 40 metres

Colour : black

Marking : TECALEMIT - PART N° - REFOULEMENT ABRASIF 5BARS - PRODUCTION DATE OR BATCH N°

Particularity : can be rolled flat with 5mm thick wall with additional micro-perforation of the outer cover

| Part N° | Inner diameter | Wall thickness | working pressure | Test pressure | Bend radius | Weight | ||

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 731 90x102 | 90 | 3”9/16 | 100 | 6 | 5 | 15 | - | 1.8 |

| 731 90x104 | 90 | 3”9/16 | 102 | 6 | 5 | 15 | - | 2.0 |

| 731 100x112 | 100 | 4" | 112 | 6 | 5 | 15 | - | 2.0 |

| 731 110x122 | 110 | 4”11/32 | 122 | 6 | 5 | 15 | - | 2.1 |

Possible end-fittings : Guillemin, Storz

| 741 | |

| DIN 53516 | |

Hose 741 is used for suction and delivery of abrasive products having an abrasion rating of 60mm3 according to DIN 53516.

It can be supplied with a parablond inner tube.

It can also be used for sand, shot, gravel, etc...

Technical specifications :

Inner tube : black anti-abrasive SBR / NR rubber

Reinforcement : 2 textile plies and 1 metal spiral

Outer cover : abrasion and weather resistant SBR rubber

Electrical conductivity : copper braid inserted between textile braids

Outer finish : wrapped

Temperature : - 30°C to +70°C

Production lengths : 20 metres

Colour : black

Marking : TECALEMIT - PART N° - ASPIRATION REFOULEMENT ABRASIF 10BARS - PRODUCTION DATE OR BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Test pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | bar | mm | kg/m | |

| 741 40 | 40 | 1”9/16 | 58 | 9 | 10 | 15 | 30 | 140 | 2.0 |

| 741 50 | 50,8 | 2” | 70 | 10 | 10 | 15 | 30 | 240 | 2.6 |

| 741 60 | 60 | 2”3/8 | 80 | 10 | 10 | 15 | 30 | 250 | 2.8 |

| 741 65 | 63,5 | 2”1/2 | 85 | 10 | 10 | 15 | 30 | 280 | 3.2 |

| 741 70 | 70 | 2”3/4 | 90 | 10 | 10 | 15 | 30 | 300 | 3.4 |

| 741 75 | 76,2 | 3” | 96 | 10 | 10 | 15 | 30 | 325 | 4.1 |

| 741 80 | 80 | 3”5/32 | 101 | 10.5 | 10 | 15 | 30 | 400 | 4.8 |

| 741 90 | 90 | 3”9/16 | 108 | 9 | 10 | 15 | 30 | 430 | 5.8 |

| 741 100 | 101,6 | 4” | 123 | 11 | 10 | 15 | 30 | 480 | 6.4 |

| 741 110 | 110 | 4”11/32 | 134 | 12 | 10 | 15 | 30 | 560 | 6.9 |

| 741 120 | 120 | 4”23/32 | 144 | 12 | 10 | 15 | 30 | 600 | 7.9 |

| 741 125 | 127 | 5” | 151 | 12 | 10 | 15 | 30 | 625 | 8.2 |

| 741 125X155 | 127 | 5” | 155 | 14 | 10 | 15 | 30 | 625 | 8.9 |

| 741 140 | 140 | 5"1/2 | 162 | 11 | 10 | 15 | 30 | 720 | 10.0 |

| 741 150 | 152,4 | 6” | 175 | 12 | 10 | 15 | 30 | 780 | 11.0 |

| 741 200 | 203,2 | 8” | 230 | 14 | 10 | 15 | 30 | 1150 | 14.0 |

| 741 219 | 219 | 8"5/8 | 250 | 15.5 | 10 | 15 | 30 | 1300 | 15.0 |

| 741 250 | 254 | 10” | 288 | 16 | 10 | 15 | 30 | 1550 | 22.0 |

Possible end-fittings : Flange, steel male thread

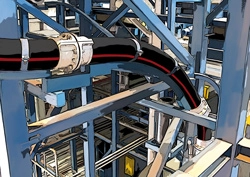

| 744 |

| |

This hose allows the assembly of flexible conducts for pneumatic handling of abrasive products, using 1/2 ISO PN cast aluminum flange shells that attach to the outside of the hose.

Assembly does not require particular formation nor specific tools.

No particular protection is necessary for its outdoor use and a simple regular visual control is sufficient.

The couplings are reusable, the replacement of the used lengths is quickly made.

Technical specifications :

Inner tube : abrasion resistant antistatic natural rubber.

Reinforcement : high tensile synthetic textile, steel wire helix and antistatic copper wire

Outer cover : abrasion, ozone and wather resistant corruged special synthetic rubber.

Outer finish : corrugated

Temperature : - 40°C to +70°C

Production lengths : variable depending on the diameter

Colour : black

Marking : TECALEMIT - PART N° - DIA X THICKNESS - BATCH N°

Abrasion loss value : acc DIN 53516 ≤ 60mm3

| Part n° | Inner diameter | Outer diameter | Negative pressure | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 744 80x113 | 80 | 3"1/8 | 113 | -0,92 | 10 | 30 | 350 | 6,584 |

| 744 101x133 | 101,6 | 4” | 133 | -0,92 | 10 | 30 | 500 | 7,663 |

| 744 127x158 | 127 | 5” | 158 | -0,92 | 10 | 30 | 650 | 9,817 |

| 744 152x183 | 152,4 | 6” | 183 | -0,92 | 10 | 30 | 750 | 12,117 |

| 744 203x234 | 203,2 | 8” | 234 | -0,92 | 10 | 30 | 1750 | 16,586 |

| 744 254x286 | 254 | 10” | 286 | -0,92 | 10 | 30 | 2000 | 22,175 |

| 744 304x341 | 304,8 | 12” | 341 | -0,92 | 10 | 30 | 2500 | 26,518 |

| 772 & 777 |

772 – Para-black 772 – Para-black | |

777 – Para-blond 777 – Para-blond | |

Hose 772 & 777 are used for pneumatically handling abrasive products.

Light and with low bend radius, there intended for vacuuming industrial dust and shavings on mobile equipments.

The 777 hose with a para-blond tube is softer than the 772.

It can be supplied in predetermined lengths with flexible cuff-ends.

Technical specifications :

Inner tube : beige natural rubber

Reinforcement : 2 textile plies and 1 interlayed metal spiral

Outer cover : abrasion and weather resistant rubber

Elecrical conductivity : copper braid interlayed between textile plies visible at cuff-ends

Outer finish : wrapped and corrugated with flexible cuff-ends

Temperature : - 30°C to +70°C

Production lengths : 40 metres or to order

Colour : black

Marking : TECALEMIT - PART N° - Ø - PS (BARS) - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | Negative pressure | Burst pressure | Bend radius | Weight | ||

| mm | Inch | mm | mm | bar | bar | mm | kg/m | ||

| 772 25 | 777 25 | 25 | 1” | 32 | 3.5 | - 0,9 | - | 150 | 0.5 |

| 772 38 | 777 38 | 38 | 1”1/2 | 46 | 4.0 | - 0,9 | - | 220 | 0.6 |

| 772 50 | 777 50 | 50,8 | 2” | 60 | 4.5 | - 0,9 | - | 270 | 0.8 |

| 772 60 | 777 60 | 60 | 2”3/8 | 69 | 4.5 | - 0,9 | - | 330 | 0.9 |

| 772 70 | 777 70 | 70 | 2”3/4 | 79 | 4.5 | - 0,9 | - | 350 | 1.0 |

| 772 75 | 777 75 | 76,2 | 3” | 85 | 4.5 | - 0,9 | - | 410 | 1.1 |

| 772 80 | 777 80 | 80 | 3”5/32 | 90 | 5.0 | - 0,9 | - | 440 | 1.5 |

| 772 100 | 777 100 | 101,6 | 4” | 112 | 5.5 | - 0,9 | - | 550 | 1.8 |

| 772 125 | 777 125 | 127 | 5” | 138 | 5.5 | - 0,9 | - | 600 | 2.8 |

| 772 150 | 777 150 | 152,4 | 6” | 163 | 5.5 | - 0,9 | - | 790 | 3.5 |

| 772 200 | 777 200 | 203,2 | 8” | 216 | 6.5 | - 0,9 | - | 1000 | 5.1 |

| 772 300 | 777 300 | 305 | 12” | 318 | 6.5 | - 0,9 | - | 1600 | 9.3 |

Possible end-fittings : Guillemin, manufacturer accessories

| Ref 787 and 788 |

787 - Para-blond 787 - Para-blond | |

788 - Para-black 788 - Para-black | |

The hoses 787 and 788 are pneumatic handling hoses for abrasive products: they can be delivered in predetermined lengths with flexible cuffs at the ends.

Their copper braids extending before the cuffs' ends allow for easier and higher-quality connections.

Technical specifications :

Inner tube 777: abrasion resistant natural rubber, thickness 5mm.

Inner tube 787: abrasion resistant black natural rubber, thickness 5mm.

Reinforcement : high tensile synthetic textile, steel wire helix and antistatic copper wire.

Outer cover: abrasion, ozone and weather resistant special synthetic rubber.

Outer finish : corrugated.

Temperature: - 40°C to +70°C

Production lengths: crowns or fixed lengths with flexible cuff-ends.

Colour : black.

Marking : TECALEMIT - PART N° - Ø - PS (BARS) - BATCH N°

| Part n° | Inner diameter | Outer diameter | working pressure | Burst pressure | Negative pressure | Bend radius | Weight | ||

| mm | Inch | mm | bar | bar | bar | mm | kg/m | ||

| 787 25 | 788 25 | 25,4 | 1’’ | 37,5 | 3 | 9 | - 0,92 | 50 | 0,80 |

| 787 32 | 788 32 | 32 | 1’’ 1/4 | 44 | 3 | 9 | - 0,92 | 65 | 0,91 |

| 787 38 | 788 38 | 38 | 1’’ 1/2 | 51 | 3 | 9 | - 0,92 | 80 | 1,23 |

| 787 50 | 788 50 | 50,8 | 2’’ | 64,5 | 3 | 9 | - 0,92 | 130 | 1,69 |

| 787 65 | 788 65 | 63,5 | 2’’ 1/2 | 77,5 | 3 | 9 | - 0,92 | 175 | 2,28 |

| 787 70 | 788 70 | 70 | 3" | 86 | 3 | 9 | -0,92 | 220 | 2,96 |

| 787 75 | 788 75 | 76,2 | 3’’ | 90,5 | 3 | 9 | - 0,92 | 250 | 2,96 |

| 787 80 | 788 80 | 80 | 3"5/32 | 95 | 3 | 9 | -0,92 | 280 | 3,40 |

| 787 90 | 788 90 | 90 | 3’’ 1/2 | 106 | 3 | 9 | - 0,92 | 300 | 3,71 |

| 787 100 | 788 100 | 101,6 | 4’’ | 119 | 3 | 9 | - 0,92 | 350 | 4,49 |

| 787 125 | 788 125 | 127 | 5’’ | 147 | 3 | 9 | - 0,92 | 450 | 6,56 |

| 787 150 | 788 150 | 152,4 | 6’’ | 173 | 3 | 9 | - 0,92 | 630 | 8,64 |

| 787 200 | 788 200 | 203,2 | 8’’ | 227 | 3 | 9 | - 0,80 | 950 | 13,6 |

| 787 250 | 788 250 | 254 | 10’’ | 279 | 3 | 9 | - 0,80 | 1200 | 16,7 |

| 791 |

| |

Hose 791 is used for the projection of various abrasive products : mortar, concrete, other coatings.

Where there is no risk of high traction, it can be used for concrete injection at 40 bars.

Its abrasion rating, according to 53516 standards, is 60mm3.

It can be equipped with swaged end-fittings.

Technical specifications :

Inner tube : smooth black natural rubber based anti-abrasive SBR / NR rubber

Reinforcement : textile braid

Outer cover : abrasion and weather resistant SBR rubber

Electrical conductivity : inner tube is conductive

outer finish : wrapped

Temperature : -30°C to +70°C max

Production lengths : 40 metres

Colour : black

Marking : TECALEMIT - PART N° - PROJECTION ABRASIF À 40 BARS - PRODUCTION DATE OR BATCH

| Part n° | Diamètre intérieur | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 791 25x38 | 25 | 1” | 38 | 6.5 | 40 | 120 | 100 | 0.75 |

| 791 35x49 | 35 | 1”3/8 | 49 | 7 | 40 | 120 | 180 | 1.1 |

| 791 50x68 | 50,8 | 2” | 68 | 8.5 | 40 | 120 | 280 | 1.95 |

| 791 65x85 | 65 | - | 85 | 10.0 | 40 | 120 | 380 | 2.9 |

| 791 76X96 | 76 | 3” | 96 | 10.0 | 40 | 120 | 600 | 3,14 |

| 791 90x112 | 90 | 3”1/2 | 112 | 10.0 | 40 | 120 | 800 | 4.1 |

Possible end-fittings : steel Cam-lock, threadeds

See also 711, 798

| 798 |

| |

In its smaller diameters, hose 798 is intended for discharge of abrasive products : mortars, plaster, cement concrete, drilling muds.

From diameter 75mm up, it is intended for spreading of pumped concrete under high pressure (80 bars).

Its metallic structure ensures it is very robust.

Its abrasion index is less than 60 mm3 according to DIN 5351G.

Very flexible, it also has a low bend radius.

It can be equipped with swaged end-fittings machined from steel ST 52 DIN 1629 / ST 52.3 DIN 17121 / ST 52.4 DIN 1630 and having undergone a hardening heat treatment.

In order to have a full flow, hose end are reamed out.

Technical specifications :

Inner tube : smooth black anti-abrasive SBR/NR rubber

Reinforcement : 2 or 4 brass-clad metal spirals

Outer cover : abrasion and weather resistant SBR rubber

Outer finish : fine tape wrapped

Temperature : -30°C to +70°C maximum

Production lengths : 40 metres

Colour : black with yellow stripe

Marking : Tecalemit - REF 798 - refoulement de béton à 85 bars - production date or batch

| Part n° | Inner diameter | Outer diameter | Wall thickness | working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 798 50 | 50,8 | 2” | 68 | 9 | 85 | 200 | 250 | 3.0 |

| 798 63 | 63,5 | 2”1/2 | 85 | 11 | 85 | 232 | 280 | 4.5 |

| 798 75 | 76 | 3” | 102 | 13 | 85 | 250 | 310 | 5.5 |

| 798 100 | 101,6 | 4” | 130 | 14 | 85 | 225 | 400 | 8.4 |

| 798 127 | 127 | 5” | 155 | 14 | 85 | 200 | 520 | 9.6 |

| 798 150 | 152,4 | 6” | 185 | 17 | 60 | 175 | 580 | 11.0 |

Possible end-fittings : Victaulic, a gorge (constructeur)

| 831 |

| |

Hose 831 is intended for discharging food products such as suger, powdered milk and flour. it is also used for discharging pvc granulates. in 5mm thickness, it can be rolled flat.

In 7mm thickness, its life span is increased by using a 5mm thick inner tube and through its “round-shape memory” which avoids kinking.

It can be delivered in lengths equipped with Guillemin fitting in aluminum or stainless steel set with socket aluminum or stainless steel.

Technical specifications :

Inner tube : white anti-abrasive food quality NR rubber

Reinforcement : 2 textile plies

Outer cover : abrasion and weather resistant CR rubber

Electrical conductivity : copper braid inserted between textile plies

Outer finish : wrapped

Temperature : - 30°C to +60°C

Production lengths : 20 metres

Colour : blue or black

Marking : TECALEMIT - PART N° - REFOULEMENT ABRASIFS ALIMENTAIRE 5 BAR - PRODUCTION DATE OR BATCH

| Part n° | Inner diameter | Outer diameter | Wall thickness | Working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 831 76x86 | 76,4 | 3” | 86 | 5 | 5 | 15 | - | 1.3 |

| 831 90x100 | 90 | 3"1/2 | 100 | 5 | 5 | 15 | - | 1.5 |

| 831 90x104 | 90 | 3"1/2 | 104 | 7 | 5 | 15 | 900 | 2.0 |

| 831 101x116 | 101,6 | 4” | 112 | 5 | 5 | 15 | 1000 | 3.0 |

| 831 110x122 | 110 | 4”11/32 | 122 | 6 | 5 | 15 | 1100 | 2.9 |

Possible end-fittings : Guillemin, Storz

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR