Storz couplings

Quick Connection Couplings, adapters, blank caps, spare Parts, seals and spanners for liquids, powders and granulates

Application areas Storz couplings

The industry, fire fighting, petroleum, chemical, pharmaceutical, food, petrochemical, construction, maintenance, agriculture, irrigation, steel mills, bulk transport tanks in liquid and powder.

Working pressure 16 bars / 225PSI

Storz couplings specifications

Storz couplings have an identical locking head with no separate male or female halves and are available with BSP male and female threads, or serrated hose tails for fitting into rubber hose.

Blank caps are available for shutting off delivery when not in use.

The maximum working pressure for this range of couplings is 16 Bar and they are stocked in aluminium alloy and brass with stainless steel units available upon request.

The Storz coupling locking head possesses 2 lugs.

Any combination of female, male, hose tail or blanking cap can be secured together with the same lug dimension.

Storz spanners are available which engage with the coupling housing to ensure a trouble free and leak proof seal is obtained.

Storz fittings are suitable for water and a wide range of other fluids. S

torz couplings are commonly used on tankers for powder blowing systems.

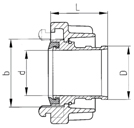

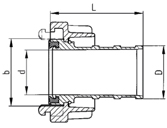

Hose couplings for external binding

Symmetrical quick connection coupling, no female and male part, no problem with matching hose ends.

Assembly and functionality of couplings Storz System.

Quick connection couplings with DS suffix generally are suitable for delivery and suction operation, without DS suffix for delivery operation only.

Working pressure is PN 16 if not mentioned otherwise..

- Aluminium alloys (A) - Copper alloys (C) - High grade steel (St)

1000 with tail pieces for delivery operation |  1001 with tail pieces for delivery and suction operation (DS) | |||||||

Ø25

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1006.000433 | 25=D-DS | 31 | 13 | 53 | 8 | 0,085 | A | |

| 1006.001033 | 25=D-DS | 31 | 21/191) | 50 | 16 | 0,090 | multiserrated | A |

| 1006.306731 | 25=D-DS | 31 | 19 | 58 | 16 | 0,090 | 1 groove | A |

| 1006.001093 | 25=D-DS | 31 | 21/191) | 50 | 16 | 0,270 | multiserrated | A |

| 1004.244433 | 25=D-DS | 31 | 25 | 53 | 18 | 0,090 | DIN14 301 | A |

| 1006.426633 | 25=D-DS | 31 | 25 | 53 | 18 | 0,090 | seal white | A |

| 1006.246333 | 25=D-DS | 31 | 25 | 60 | 18 | 0,095 | 1 groove | A |

| 1006.326333 | 25=D-DS | 31 | 25 | 50 | 18 | 0,090 | PN 40 | A |

| 1004.244593 | 25=D-DS | 31 | 25 | 53 | 18 | 0,280 | A | |

| 1004.244599 | 25=D-DS | 31 | 25 | 53 | 18 | 0,280 | PN 40 | A |

| 1004.321046 | 25=D-DS | 31 | 25 | 53 | 18 | 0,250 | A | |

| 1004.244432 | 25=D-DS | 31 | 25 | 53 | 18 | 0,090 | cast PN 10 | A |

Ø38

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1006.197233 | 38-DS | 51 | 25 | 65 | 18 | 0,180 | A | |

| 1006.197293 | 38-DS | 51 | 25 | 65 | 18 | 0,530 | A | |

| 1006.265093 | 38 | 51 | 25 | 90 | 18 | 0,680 | PN 40 | A |

| 1006.002933 | 38-DS | 51 | 35/32 1) | 90 | 27 | 0,190 | A | |

| 1006.003333 | 38-DS | 51 | 38 | 90 | 30 | 0,210 | A | |

| 1006.174593 | 38 | 51 | 38 | 90 | 30 | 0,700 | PN 40 | A |

Ø45

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1006.279233 | 45-DS | 59 | 45 | 72 | 37 | 0,220 | A |

Ø52

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1006.028333 | 52=C | 66 | 19 | 42 | 13 | 0,380 | tail 50° bent | A |

| 1006.100333 | 52=C-DS | 66 | 22/19 1) | 90 | 15 | 0,350 | multiserrated | A |

| 1006.024033 | 52=C | 66 | 25 | 41 | 18 | 0,380 | tail 50° bent | A |

| 1006.024093 | 52=C | 66 | 25 | 41 | 18 | 1,025 | tail 50° bent | A |

| 1006.005333 | 52=C-DS | 66 | 25 | 90 | 18 | 0,360 | A | |

| 1006.005332 | 52=C-DS | 66 | 25 | 90 | 18 | 0,360 | cast PN 10 | A |

| 1006.005393 | 52=C-DS | 66 | 25 | 90 | 18 | 0,900 | A | |

| 1006.483593 | 52=C-DS | 66 | 25 | 90 | 25 | 1,015 | PN 40 | A |

| 1004.426946 | 52=C-DS | 66 | 25 | 90 | 18 | 0,815 | A | |

| 1006.005433 | 52=C | 66 | 28 | 95 | 24 | 0,320 | A | |

| 1006.268433 | 52=C | 66 | 34/32 1) | 90 | 25 | 0,380 | A | |

| 1006.307333 | 52=C-DS | 66 | 34/32 1) | 90 | 25 | 0,400 | A | |

| 1006.307332 | 52=C-DS | 66 | 34/32 1) | 90 | 25 | 0,400 | cast PN 10 | A |

| 1006.110193 | 52=C-DS | 66 | 34/32 1) | 100 | 26 | 0,980 | A | |

| 1006.406546 | 52=C-DS | 66 | 32 | 90 | 26 | 0,845 | A | |

| 1006.107893 | 52=C-DS | 66 | 38 | 90 | 30 | 1,150 | withearthscrew | A |

| 1006.024333 | 52=C-DS | 66 | 38 | 90 | 31 | 0,370 | A | |

| 1006.024332 | 52=C-DS | 66 | 38 | 90 | 31 | 0,370 | cast PN 10 | A |

| 1006.006733 | 52=C | 66 | 38 | 90 | 31 | 0,375 | A | |

| 1006.024393 | 52=C-DS | 66 | 38 | 90 | 32 | 1,135 | A | |

| 1004.394846 | 52=C-DS | 66 | 38 | 90 | 32 | 0,800 | A | |

| 1006.569533 | 52=C-DS | 66 | 40 | 70 | 30 | 0,380 | A | |

| 1006.007133 | 52=C | 66 | 40 | 70 | 31 | 0,375 | Swiss-Standard | A |

| 1004.266233 | 52=C | 66 | 42 | 55 | 36 | 0,335 | DIN14 332 | A |

| 1006.100933 | 52=C-DS | 66 | 42 | 90 | 33 | 0,360 | A | |

| 1006.100932 | 52=C-DS | 66 | 42 | 90 | 33 | 0,360 | cast PN 10 | A |

| 1006.100993 | 52=C-DS | 66 | 42 | 90 | 33 | 0,965 | A | |

| 1006.008233 | 52=C | 66 | 45 | 68 | 38 | 0,355 | A | |

| 1006.008333 | 52=C | 66 | 45 | 90 | 37 | 0,370 | A | |

| 1006.008393 | 52=C | 66 | 45 | 90 | 37 | 0,900 | A | |

| 1006.016633 | 52=C-DS | 66 | 45 | 90 | 37 | 0,380 | A | |

| 1006.016632 | 52=C-DS | 66 | 45 | 90 | 37 | 0,380 | cast PN 10 | A |

| 1006.637733 | 52=C-DS | 66 | 50 | 90 | 42 | 0,380 | A | |

| 1006.556433 | 52=C-DS | 66 | 51 | 90 | 45 | 0,350 | multiserrated | A |

| 1004.244633 | 52=C | 66 | 52 | 55 | 45 | 0,320 | DIN14 302 | A |

| 1004.244632 | 52=C | 66 | 52 | 55 | 45 | 0,320 | cast PN 10 | A |

| 1004.244793 | 52=C | 66 | 52 | 75 | 45 | 0,970 | DIN86 202 | A |

| 1006.132693 | 52=C | 66 | 52 | 75 | 45 | 0,980 | withearthscrew | A |

| 1006.105233 | 52=C | 66 | 52 | 90 | 45 | 0,350 | A | |

| 1006.105293 | 52=C | 66 | 52 | 90 | 45 | 1,095 | A | |

| 1004.245233 | 52=C-DS | 66 | 52 | 90 | 45 | 0,365 | DIN14 321 | A |

| 1006.152232 | 52=C-DS | 66 | 52 | 90 | 45 | 0,355 | cast PN 10 | A |

| 1006.452933 | 52=C-DS | 66 | 52 | 90 | 45 | 0,335 | seal silicone | A |

| 1006.152259 | 52=C-DS | 66 | 52 | 90 | 45 | 0,250 | completePolyamid PN 10 | A |

| 1006.107793 | 52=C-DS | 66 | 62 | 90 | 45 | 0,925 | withearthscrew | A |

| 1004.245293 | 52=C-DS | 66 | 52 | 90 | 45 | 0,935 | A | |

| 1006.400193 | 52=C-DS | 66 | 52 | 90 | 45 | 1,060 | PN 40 | A |

| 1004.039446 | 52=C-DS | 66 | 52 | 90 | 45 | 0,750 | A | |

| 1006.010333 | 52=C | 66 | 55 | 70 | 44 | 0,350 | Swiss-Standard | A |

| 1006.017233 | 52=C-DS | 66 | 55 | 120 | 44 | 0,410 | Swiss-Standard | A |

| 1006.504333 | 52=C-DS | 66 | 60 | 90 | 50 | 0,385 | A |

Ø65

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1006.493333 | 65 | 81 | 38 | 90 | 28 | 0,450 | A | |

| 1006.335033 | 65-DS | 81 | 38 | 90 | 28 | 0,450 | A | |

| 1006.335093 | 65-DS | 81 | 38 | 90 | 28 | 1,430 | A | |

| 1006.011333 | 65 | 81 | 52 | 60 | 45 | 0,450 | NEN 3374 | A |

| 1006.011532 | 65 | 81 | 52 | 90 | 45 | 0,490 | cast PN 10 | A |

| 1006.011533 | 65 | 81 | 52 | 90 | 45 | 0,490 | A | |

| 1006.175893 | 65 | 81 | 52 | 90 | 45 | 1,380 | A | |

| 1006.461946 | 65-DS | 81 | 52 | 90 | 45 | 1,410 | A | |

| 1006.221493 | 65-DS | 81 | 63 | 100 | 55 | 1,450 | A | |

| 1006.541433 | 65-DS | 81 | 63,5 | 100 | 55 | 0,500 | A | |

| 1006.011833 | 65 | 81 | 65 | 59 | 58 | 0,420 | NEN 3374 | A |

| 1006.011893 | 65 | 81 | 65 | 59 | 58 | 1,265 | A | |

| 1006.012133 | 65 | 81 | 65 | 100 | 55 | 0,475 | A | |

| 1006.012132 | 65 | 81 | 65 | 100 | 55 | 0,475 | cast PN 10 | A |

| 1006.017333 | 65-DS | 81 | 65 | 100 | 55 | 0,505 | A | |

| 1006.017332 | 65 | 81 | 65 | 100 | 55 | 0,505 | cast PN 10 | A |

| 1006.461846 | 65-DS | 81 | 65 | 90 | 58 | 1,200 | A | |

| 1006.651133 | 65-DS | 81 | 65 | 95 | 57 | 0,530 | multiserrated | A |

| 1006.012233 | 65 | 81 | 70 | 80 | 58 | 0,550 | A | |

| 1006.498033 | 65-DS | 81 | 70 | 95 | 58 | 0,590 | A | |

| 1006.012433 | 65 | 81 | 75 | 65 | 58 | 0,410 | NEN 3374 | A |

| 1006.012833 | 65 | 81 | 75 | 100 | 58 | 0,520 | A | |

| 1006.012832 | 65 | 81 | 75 | 100 | 58 | 0,520 | cast PN 10 | A |

Ø75

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1004.379233 | 75=B-DS | 89 | 52 | 125 | 44 | 0,700 | A | |

| 1006.013633 | 75=B | 89 | 65 | 80 | 65 | 0,550 | A | |

| 1006.017533 | 75=B-DS | 89 | 65 | 125 | 55 | 0,715 | A | |

| 1006.017532 | 75=B-DS | 89 | 65 | 125 | 55 | 0,715 | cast PN 10 | A |

| 1006.017508 | 75=B-DS | 89 | 65 | 125 | 55 | 0,705 | seal silicone | A |

| 1006.017593 | 75=B-DS | 89 | 65 | 125 | 55 | 1,945 | A | |

| 1004.408846 | 75=B-DS | 89 | 65 | 125 | 58 | 1,650 | A | |

| 1006.014033 | 75=B | 89 | 70 | 75 | 60 | 0,550 | A | |

| 1006.452033 | 75=B | 89 | 70 | 125 | 60 | 0,700 | A | |

| 1006.017633 | 75=B-DS | 89 | 70 | 125 | 60 | 0,720 | A | |

| 1004.244833 | 75=B | 89 | 75 | 60 | 65 | 0,560 | DIN14 303 | A |

| 1004.244832 | 75=B | 89 | 75 | 60 | 65 | 0,560 | cast PN 10 | A |

| 1004.244993 | 75=B | 89 | 75 | 80 | 65 | 1,410 | DIN86 203 | A |

| 1006.151393 | 75=B | 89 | 75 | 80 | 65 | 1,430 | withearthscrew | A |

| 1006.014733 | 75=B | 89 | 75 | 83 | 65 | 0,600 | Swiss-Standard | A |

| 1006.014833 | 75=B | 89 | 75 | 125 | 65 | 0,670 | A | |

| 1004.245933 | 75=B-DS | 89 | 75 | 125 | 65 | 0,710 | DIN14 322 | A |

| 1006.316432 | 75=B-DS | 89 | 75 | 125 | 65 | 0,670 | cast PN 10 | A |

| 1006.462633 | 75=B-DS | 89 | 75 | 125 | 65 | 0,700 | seal silicone | A |

| 1006.172844 | 75=B-DS | 89 | 75 | 125 | 65 | 1,395 | tail pc.steel 2) | A |

| 1004.245993 | 75=B-DS | 89 | 75 | 125 | 65 | 1,865 | A | |

| 1004.039546 | 75=B-DS | 89 | 75 | 105 | 67 | 1,580 | A | |

| 1006.556533 | 75=B-DS | 89 | 76 | 125 | 65 | 0,730 | multiserrated | A |

| 1006.017933 | 75=B-DS | 89 | 80 | 125 | 65 | 0,730 | A | |

| 1006.017932 | 75=B-DS | 89 | 80 | 125 | 65 | 0,730 | cast PN 10 | A |

| 1006.017944 | 75=B-DS | 89 | 80 | 125 | 65 | 1,770 | tail pc.steel 2) | A |

| 1004.410046 | 75=B-DS | 89 | 80 | 105 | 65 | 1,400 | A |

Ø90

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1006.018433 | 90-DS | 105 | 90 | 140 | 80 | 0,970 | A |

Ø100

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1006.015133 | 100 | 115 | 101 | 84 | 90 | 0,950 | A | |

| 1006.018533 | 100-DS | 115 | 101 | 150 | 90 | 1,230 | A |

Ø110

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1006.015333 | 110=A-DS | 133 | 90 | 170 | 80 | 1,600 | A | |

| 1006.015533 | 110=A-DS | 133 | 100 | 170 | 90 | 1,630 | A | |

| 1006.015532 | 110=A-DS | 133 | 100 | 170 | 90 | 1,695 | cast PN 10 | A |

| 1006.461733 | 110=A-DS | 133 | 100 | 170 | 90 | 1,600 | seal silicone | A |

| 1003.350844 | 110=A-DS | 133 | 100 | 170 | 90 | 2,960 | tail pc.steel 2) | A |

| 1006.015593 | 110=A-DS | 133 | 100 | 170 | 90 | 4,350 | cast PN 10 | A |

| 1003.228546 | 110=A-DS | 133 | 100 | 170 | 90 | 3,550 | A | |

| 1006.015633 | 110=A-DS | 133 | 101 | 130 | 90 | 1,480 | A | |

| 1006.556633 | 110=A-DS | 133 | 102 | 170 | 90 | 1,700 | multi serrated | A |

| 1004.245033 | 110=A-DS | 133 | 110 | 115 | 100 | 1,445 | A | |

| 1004.246333 | 110=A-DS | 133 | 110 | 170 | 100 | 1,660 | DIN14 323 | A |

| 1006.306832 | 110=A-DS | 133 | 110 | 170 | 100 | 1,650 | cast PN 10 | A |

| 1004.246393 | 110=A-DS | 133 | 110 | 170 | 100 | 5,000 | cast PN 10 | A |

| 1003.235346 | 110=A-DS | 133 | 110 | 170 | 102 | 3,300 | A | |

| 1006.019033 | 110=A-DS | 133 | 125 | 200 | 100 | 1,900 | A |

Ø125

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1006.018733 | 125-DS | 148 | 125 | 197 | 113 | 2,300 | A | |

| 1006.018746 | 125-DS | 148 | 125 | 197 | 113 | 5,320 | A | |

| 1006.019193 | 125-DS | 148 | 125 | 220 | 113 | 7,300 | cast PN 10 | A |

Ø135

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Référence | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | |||||

| 1006.019533 | 135-DS | 159 | 135 | 250 | 124 | 2,565 | 60019533 | cast PN 10 | A |

Ø150

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1006.359033 | 150-DS | 160 | 150 | 180 | 130 | 2,700 | 3 lugs | A |

| 1006.359095 | 150-DS | 160 | 150 | 180 | 130 | 8,000 | 3 lugs,cast PN 10 | A |

| 1006.430646 | 150-DS | 160 | 150 | 180 | 130 | 7,430 | 3 lugs | A |

| 1006.665133 | 150-DS | 160 | 152 | 180 | 130 | 3,600 | 3 lugs,multi serrated | A |

Ø165

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1006.019833 | 165-DS | 188 | 152 | 275 | 138 | 3,900 | cast PN 10 | A |

Ø205

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1006.020133 | 205-DS | 220 | 205 | 375 | 183 | 6,800 | cast PN 10 | A |

| 1006.588733 | 205-DS | 220 | 205 | 375 | 183 | 6,800 | Jumbo Storz8", 3 lugs | A |

Ø250

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1006.668833 | 250 | 278 | 260 | 400 | 242 | 12,400 | JumboStorz10",3 lugs | A |

Ø305

| Part N° | Nominal size | Lug spacing b | For hose i. d | Length tail piece L | Inside dia. | Weight | Remarks | Alloy |

| (mm) | (mm) | (mm) | (mm) | (kg) | ||||

| 1006.668933 | 305 | 316 | 305 | 425 | 280 | 14,900 | JumboStorz12",3 lugs | A |

1 : Inside diameter of rubber hose approx. 2mm smaller than tail piece diameter

2 : A wear-resistant coupling for use abrasive media. this means much longer life than the light alloy version

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR