Clamp type coupling NF EN 14423

Clamp type coupling assemblies for use with steam hoses rated for pressures up to 18 bar

Fittings with threading or flanges have been specially designed for assembling half-shells onto steam hoses and are guaranteed for a maximum operating pressure of 160 bars at 20°C or 18 bars at 210°C.

They are widely used for air, water, liquid oil, liquid chemicals, and petroleum gases up to 1".

These steam fittings can be installed on various types of synthetic rubber, plastic, metallic, or semi-metallic hoses.

Materials:

Bronze or Stainless Steel for shells

Steel, Brass, or Stainless Steel for threaded ends

Steel or Stainless Steel for flanged ends

Compliant with DIN 2826 and EN 14423:2004 standards

Steam hose coupling

Types de raccords

Sizes : DN13 to DN25.

Pressure (All sizes): Maximum working pressure 18 bar.

Maximum working temperature : Steam +210°C (410°F) - Hot Water +120°C (248°F)

Details : Suitable for fixing to steam hoses to BS EN 14423:2004 with safety clamps. All steam fittings are supplied with corresponding brass safety clamps.

| |||

| BS EN 14423:2004 STEAM HOSE FEMALE COUPLING | |||

| PART NO. | HOSE SIZE | THREAD | MATERIAL |

| SCF13x6 Br | 13 x 6 | 1/2” BSP Pl. | Brass |

| SCF19x7 Br | 19 x 7 | 3/4” BSP Pl. | Brass |

| SCF25x7.5 Br | 25 x 7.5 | 1” BSP Pl. | Brass |

| |||

| BS EN 14423:2004 STEAM HOSE MALE COUPLING | |||

| PART NO. | HOSE SIZE | THREAD | MATERIAL |

| SCM13x6 Br | 13 x 6 | 1/2” BSPT | Brass |

| SCM19x7 Br | 19 x 7 | 3/4” BSPT | Brass |

| SCM25x7.5 Br | 25 x 7.5 | 1” BSPT | Brass |

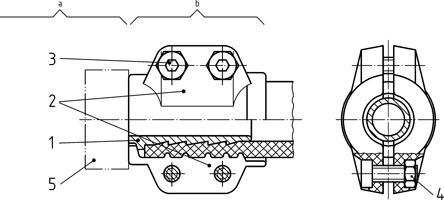

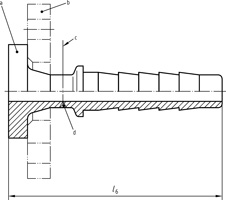

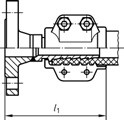

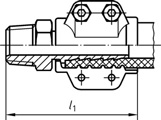

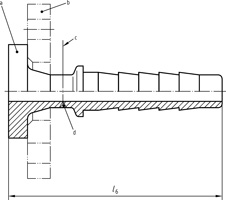

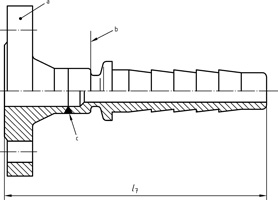

Coupling assembly

Coupling assembly

For 1 to 5 see Table

a : Connector end

b : Tail end

| ||

| List of coupling assembly components | ||

| Item number | Number of parts needed for one assembly | Denomination |

| 1 | 1 | Tail end fitting |

| 2 | 2 | Clamp |

| 3 | 4 | Hexagon socket head cap screw |

| 4 | 4 | Hexagon nut |

| 5 | 1 | Connector |

Types of connectors

Types of connectors

| Illustration | Type | Description | Nominal size DN | Thread size | L1 ≈ mm | Details |

| FL | PN 40 loose flange with weld-neck collar as in EN 1092-1 | 15 20 25 32 40 50 | 110 115 115 125 140 155 |  | |

| FV | PN 40 weld-neck flange as in EN 1092-1 |  | |||

| G | Union nut with thread gasket, with parallel thread according to EN ISO 228-1a | 15 20 25 32 40 50 | G ½ G ¾ G 1 G 1¼ G 1½ G 2 | 80 80 80 90 105 115 |  |

| GA | Tapered male thread with external thread according to EN 10226-1a | 15 20 25 32 40 50 | R ½ R ¾ R 1 R 1¼ R 1½ R 2 | 95 95 100 110 125 140 |  |

| a Other threads may be agreed between the purchaser and manufacturer. | ||||||

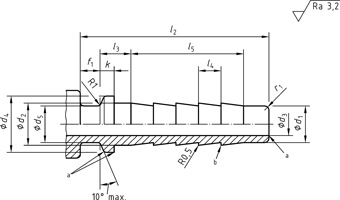

Tail end fittings

Tail end fittings

The tail end fittings of hose couplings shall have the dimensions given in Table.

Their outer surface shall be formed by machining, the surface roughness Ra of 3,2 μm.

a : Deburred

b : Ribs

Dimensions in millimetres

| |||||||||||||

| Nominal size DN | d1 ± 0,2 | d2 ± 0,2 | d3 ± 0,3 | d4 ± 1,0 | d5 ± 0,1 | f1 + 0,5 0 | k 0 − 0,2 | l2 ± 1 | l3 | Number or ribs | l4 | l5 | r1 |

| 15 | 13 | 15 | 9 | 20 | 13 | 6 | 4 | 62 | 9 | 4 | 8 | 40 | 2 |

| 20 | 19 | 21 | 14 | 26 | 19 | 6 | 4 | 62 | 9 | 4 | 8 | 40 | 2 |

| 25 | 25 | 27 | 20 | 33 | 25 | 6 | 4 | 62 | 9 | 4 | 8 | 40 | 2 |

| 32 | 32 | 34 | 27 | 40 | 32 | 7 | 5 | 72 | 9 | 5 | 8 | 48 | 2 |

| 40 | 38 | 40,5 | 33 | 46 | 38 | 7 | 5 | 84 | 13 | 5 | 10 | 60 | 2,5 |

| 50 | 50 | 52,5 | 44 | 59 | 50 | 8 | 6 | 89 | 12 | 5 | 10 | 60 | 2,5 |

Connectors

Hose fittings with weld-neck collar (for loose flanges) (FL)

The weld-neck collar may either be integral to the tail end fitting or welded to it.

The maximum length of type FL and FV fittings shall be in accordance with Table.

Weld-neck collar PN 40 according to EN 1092-1

Loose flange PN 40 according to EN 1092-1

| Maximum length of type FL and FV fittings | |

| Nominal size DN | l6, l7 max. |

| 15 | 108 |

| 20 | 110 |

| 25 | 110 |

| 32 | 122 |

| 40 | 137 |

| 50 | 149 |

EXAMPLE : | |

Hose fittings with weld-neck flange (FV)

Weld-neck flange PN 40

| Maximum length of type FL and FV fittings | |

| Nominal size DN | l6, l7 max. |

| 15 | 108 |

| 20 | 110 |

| 25 | 110 |

| 32 | 122 |

| 40 | 137 |

| 50 | 149 |

EXAMPLE : | |

Welding connections

Welding weld-neck collars to the tail end is optional for type FL fittings.

Weld-neck flanges of type FV hose fittings shall be jointed with the tail end fitting by welding.

Weld details shall be according to Table.

The welding procedures shall be in accordance with EN ISO 15607.

a : Flange or weld-neck

b : Tail end fitting

| Weld details | |||

| Nominal size DN | d6 | l8 | s1 |

| 15 | 21,3 | 8 | 3,2 |

| 20 | 26,9 | ||

| 25 | 33,7 | ||

| 32 | 42,4 | 9 | 3,6 |

| 40 | 48,3 | 9 | 3,6 |

| 50 | 60,3 | 10 | 4 |

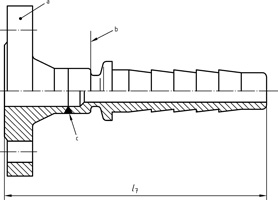

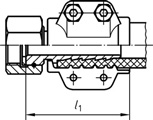

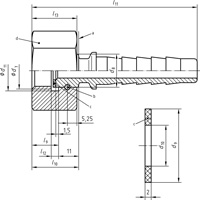

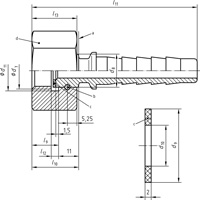

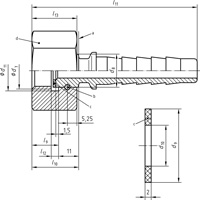

Hose fittings with union nut, thread according to EN ISO 228-1

A hose fitting with union nut (Type G) is shown in Figure.

The design of type G hose fittings shall be in accordance with Table.

a : Tail end fitting

b : Wire ring ∅ 3 mm, nearly closed

c : Thread gasket

d : Width across flats, s

| Hose fitting with union nut | |||||||||||

| Nominal size DN | Thread size as in EN ISO 228-1 a d7 | d8 | d9 0 − 0,5 | d10 ± 1 | d11 + 0,2 0 | l9 | l10 + 0,5 0 | l11 | l12 | l13 | s |

| 15 | G ½ | 18,3 | 20 | 13 | 21,5 | 9,5 | 20,5 | 82,5 | 4 | 20 | 27 |

| 20 | G ¾ | 24 | 26 | 18 | 26,5 | 13,5 | 24,5 | 86,5 | 24 | 32 | |

| 25 | G 1 | 30,2 | 33 | 23 | 33,5 | 14,5 | 25,5 | 87,5 | 5 | 25 | 41 |

| 32 | G 1¼ | 38,8 | 42 | 33 | 42,5 | 14,5 | 25,5 | 97,5 | 50 | ||

| 40 | G 1½ | 44,8 | 48 | 38 | 48,5 | 16,5 | 27,5 | 111,5 | 27 | 55 | |

| 50 | G 2 | 56,5 | 60 | 49 | 60,5 | 17,5 | 28,5 | 119,5 | 28 | 70 | |

| a : Other types of threads are to be agreed between purchaser and manufacturer. | |||||||||||

EXAMPLE 1 : EXAMPLE 2 : | |||||||||||

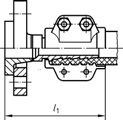

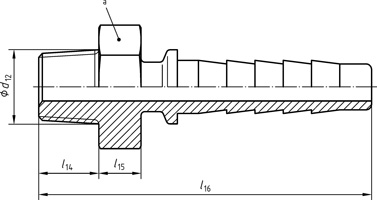

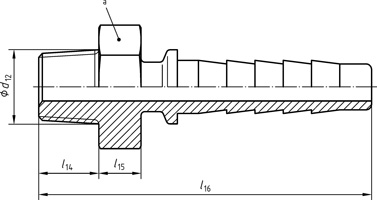

Hose fittings with tapered male thread

A hose fitting with tapered male thread (Type R) is shown in Figure.

The design of type R hose fittings shall be in accordance with Table.

a : Width across flats

| Dimensions of R type fittings | |||||

| Nominal size DN | Thread sizes as in EN 10226-1a d12 | l14 min. | l15 | l16 | s |

| 15 | R ½ | 16 | 12 | 90 | 22 |

| 20 | R ¾ | 17 | 12 | 91 | 27 |

| 25 | R 1 | 21 | 12 | 95 | 36 |

| 32 | R 1¼ | 21 | 12 | 105 | 46 |

| 40 | R 1½ | 22 | 12 | 118 | 50 |

| 50 | R 2 | 26 | 14 | 131 | 60 |

a : Other types of threads are to be agreed between purchaser and manufacturer. | |||||

EXAMPLE : | |||||

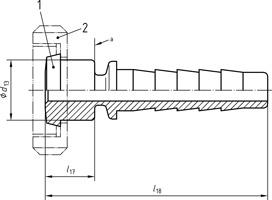

Hose fittings with coned end (RI)

A hose fitting with coned end (Type RI) is shown in Figure.

The design of type RI hose fittings shall be in accordance with Table.

1 : Cone end

2 : Grooved union nut

a : Tail end fitting

| Nominal size DN | a Type of cone end | d | l | l |

| 15 | B15 | 24 | 17 | 79 |

| 20 | B20 | 30 | 18 | 80 |

| 25 | B25 | 35 | 22 | 84 |

a : Type of conical end should be in accordance with DIN 11851. | ||||

EXAMPLE : | ||||

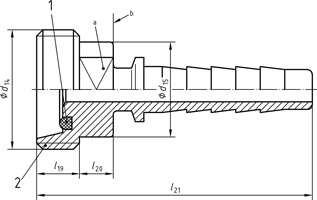

Hose fittings with stud end (RA)

A hose fitting with stud end (Type RA) is shown in Figure.

The design of type RA hose fittings shall be in accordance with Table

1 : Main gasket

2 : Stud end

a : Width across flats

b : Tail end fitting

| Dimensions of RA type hose fittings | ||||||

| Nominal size DN | Thread size d14 | d15 | l19 | l20 | l21 | S |

| 15 | Rd 34 × 1/8 | 28 | 12 | 9 | 83 | 24 |

| 20 | Rd 44 × 1/6 | 31 | 14 | 10 | 86 | 27 |

| 25 | Rd 52 × 1/6 | 40 | 14 | 11 | 87 | 36 |

EXAMPLE : | ||||||

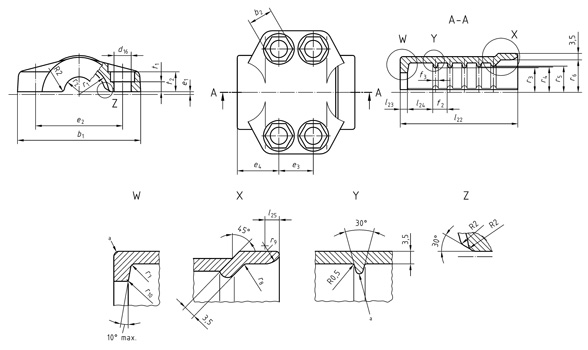

Clamps

Clamps EN 14423

Clamp designs are given in Figure.

Clamps shall be designed according to dimensions specified in Table.

EXAMPLE :

Ordering designation for a clamp (KBS), for use with DN 20 hoses, in wrought copper alloy (CW614N):

Clamp EN 14423 — KBS 20 — CW614N

| Clamp dimensions | ||||||||||||||||

| Nominal size DN | b1 | b2 | d16 | Number of ribs | e1 | e2 ± 0,2 | e3 ± 0,2 | e4 | f2 | f3 | l22 | l23 | l24 | l25 | ||

| Tolerances | ||||||||||||||||

| 15 | 53 | ± 1 | 10,3 | 7 | 5 | 1,5 | 37 | 16 | 24,5 | 8 | 3 | 65 | 4 | 14,5 | 3 | |

| 20 | 68 | ± 2 | 13,4 | 9,5 | 5 | 1,5 | 48 | 19 | 23 | 8 | 3 | 65 | 4 | 14 | 4 | |

| 25 | 77 | + 3 − 2 | 13,4 | 9,5 | 5 | 1,5 | 58 | 19 | 23 | 8 | 3 | 65 | 4 | 14,5 | 4 | |

| 32 | 86 | 13,4 | 9,5 | 5 | 2,5 | 65 | 20 | 20 | 8 | 3 | 75 | 5 | 14 | 5 | ||

| 40 | 101 | 17,3 | 12 | 6 | 2,5 | 75 | 28 | 25 | 10 | 4 | 90 | 5 | 17 | 5 | ||

| 50 | 111 | 17,3 | 12 | 6 | 2,5 | 86 | 28 | 36 | 10 | 4 | 100 | 6,5 | 18,5 | 5 | ||

| Clamp dimensions | |||||||||||||||||||||||

| Nominal size DN | r1 | r2 | r3 | r4 | r5 | Number of ribs | |||||||||||||||||

| Tolerances | Tolerances | Tolerances | Tolerances | Tolerances | with r3 | with r4 | with r5 | ||||||||||||||||

| 15 | 12,5 | ± 0,25 | 6,75 | ± 0,2 | 9,5 | ± 0,2 | 10 | ± 0,2 | 10,5 | ± 0,25 | 3 | 1 | 1 | ||||||||||

| 20 | 16,5 | 9,75 | 13,5 | ± 0,25 | 14 | ± 0,25 | 14,5 | 3 | 1 | 1 | |||||||||||||

| 25 | 20 | ± 0,3 | 12,75 | ± 0,25 | 17 | 17,5 | 18 | 3 | 1 | 1 | |||||||||||||

| 32 | 24,5 | 16,5 | 21,5 | ± 0,3 | 22 | ± 0,3 | 22,5 | ± 0,3 | 3 | 1 | 1 | ||||||||||||

| 40 | 27,5 | 19,5 | ± 0,3 | 24,5 | 25 | 25,5 | 3 | 2 | 1 | ||||||||||||||

| 50 | 34,5 | ± 0,4 | 25,5 | 31 | ± 0,4 | 31,5 | ± 0,4 | 32 | ± 0,4 | 3 | 2 | 1 | |||||||||||

| Clamp dimensions | |||||||||||

| Nominal size DN | r6 | r7 | r8 | r9 | r10 | t1 | t2 | ||||

| Tolerances | |||||||||||

| 15 | 14 | ± 0,25 | 1 | 1 | 4 | 0,5 | 5 | 10 | |||

| 20 | 18 | 1 | 1 | 5 | 0,5 | 5,5 | 11 | ||||

| 25 | 21,5 | ± 0,3 | 1 | 1 | 5 | 0,5 | 6 | 12 | |||

| 32 | 26 | 2 | 3 | 6 | 1 | 6 | 12 | ||||

| 40 | 29 | 2 | 3 | 6 | 1 | 7 | 17 | ||||

| 50 | 35 | ± 0,4 | 2,5 | 3 | 6 | 1,3 | 7 | 17 | |||

Bolts and nuts

Bolts and nuts

| Bolts and nuts | |||||||

| Nominal size DN | Size of screw as in EN ISO 4762 | Size of nuts as in EN ISO 4032 | |||||

| 15 | M6 × 20 | M6 | |||||

| 20 | M8 × 25 | M8 | |||||

| 25 | M8 × 25 | M8 | |||||

| 32 | M8 × 25 | M8 | |||||

| 40 | M10 × 40 | M10 | |||||

| 50 | M10 × 40 | M10 | |||||

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR