Tecalemit RCMH: Industrial Hose Manufacturing

Design and manufacture of flexible hoses for fluid or power transfer.

Our comprehensive range of rubber, PVC, and stainless steel hoses enables the transport of various fluids for all types of applications.

With our certifications, approvals, experience, and the development of a high-capacity crimping press, we offer a wide range of crimped hoses with large diameters and non-standard sizes.

Our engineering department and industrial capabilities allow us to design and manufacture high-quality flexible piping in compliance with legislation and tailored to the needs and specifications of our clients.

We handle the design, industrialization, production, quality control, and customer support in the field of flexible piping and industrial fittings.

Design, industrialization, production, and customer support:

At Tecalemit RCMH, we continuously strive to enhance the efficiency of our products and innovate to enable our customers to go further in their projects.

We develop and implement new assembly methods and techniques to push the performance limits of our products.

Collaborating with our partners, we develop new materials that lead to unmatched results in our industry.

Tecalemit RCMH designs its own testing benches and performs internal testing.

Innovation and research are essential factors in our shared competitiveness.

Integrated development systems:

Our integrated development systems, comprising an engineering department, machining unit, product prototyping, and internal control and testing facilities, provide us with efficiency and competitiveness.

This system entails mastery of the materials used for machining and manufacturing rubber hoses.

Normative validations are conducted by external organizations.

Technical assistance and consulting:

1 Rue le Normant des Varannes, Parc d'activités de Kermaria, 29120 PONT L'ABBE

Phone: : +(33) 02 98 66 05 050

Our engineering department offers customizable services based on your specific needs:

Industrialization documentation:

The development of engineering processes requires expertise in preparing industrialization documentation. We create this documentation according to various specifications, including:

- Price analysis.

- Document management: FAT (Factory Acceptance Test), NDT (Non-Destructive Testing), welding.

- ITP (Inspection and Test Plan).

- Third-party inspections (BV, Lloyds, etc.).

- Painting and welding documentation.

- Dedicated drawings.

- Production schedules.

- Data sheets.

These documents are prepared in both French and English. Other languages are available upon request.

Prototyping:

Rigorous management of product development methods is essential to meet technical and economic parameters. Our prototyping capabilities allow us to test:

- Alternative solutions.

- Validate technical and/or technological solutions for future products (appearance, ergonomics, processes, etc.).

- Work concurrently and in a coordinated manner within a concurrent engineering context.

- Optimize the product.

Modeling/numerical simulation:

We provide 2D and 3D modeling and simulations of equipment layouts in accordance with specific requirements from our clients. Our capabilities include:

- 2D/3D design software.

- Simulation software.

- Realistic project rendering.

Testing and quality control:

Our internal testing and quality control capabilities include:

- Hydrostatic testing bench (22 meters).

- Hydrostatic testing bench (2500 bars).

- Depollution bench.

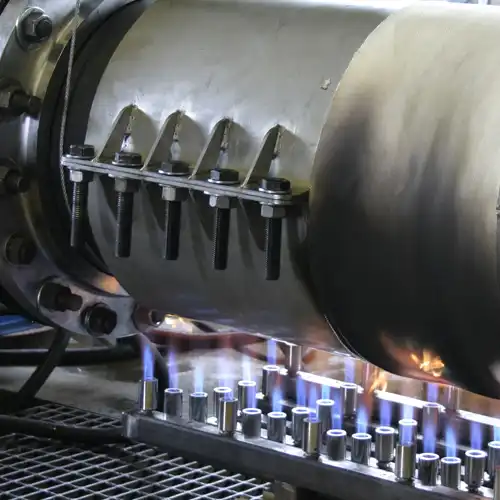

- Fire testing bench.

- Tensile testing bench.

- Insulation testing.

- PMI testing (Material Characterization).

- Weld inspection using dye penetrant.

- Pressure impulse testing bench (1000 bars - 150°C - 1 Hz).

External testing validations:

- BV (Bureau Veritas).

- LLOYD'S.

Machining:

Our Tecamec machining department allows us to produce products tailored to our clients' specific needs. Our capabilities include:

- CNC and conventional turning, CNC milling, TIG, and MIG welding.

- Cutting, stamping, deburring.

Materials:

Our expertise in materials specific to our industry allows us to have a dual competence in material development and characterization.

This includes knowledge of manufacturing processes and associated safety issues.

Our approach focuses on excellence in the following areas:

- Quality control in material measurement and development.

- Technological innovation mastery.

- Knowledge and mastery of methods and tools for project realization.

- Proficiency in laboratory testing and experimentation tools.

- Statistical and computer tool proficiency (word processing, spreadsheet, database) for data analysis and processing.

- Expertise in material development, characterization, and control.

Examples of materials:

- Stainless steel / Hastelloy / Duplex / Super Duplex / Uranus B6 / special steels / bronze.

- PTFE / PP.

- Various rubber materials / bellows / end fittings / floating hoses / PTFE.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR