Manufacturing of Hydraulic Hoses

Nuclear Industry - Shipbuilding - Railway Industry - National Defense

Tecalemit Flexibles is a recognized specialist in the design and production of custom hydraulic hoses, meeting the requirements of strategic industries such as nuclear, shipbuilding, rail, and national defense.

Thanks to our expertise in materials and rigorous inspections, we guarantee high-performance, reliable products that comply with the most stringent standards.

Nuclear Industry

Hydraulic Hoses for the Nuclear Sector

With several years of experience in designing and manufacturing complex hoses, we provide reliable and secure solutions for nuclear power plants and submarines.

Every product we develop incorporates strict safety requirements, ensuring optimal resistance to extreme conditions.

Our Commitments to Nuclear Safety

Traceability and compliance with the highest standards:

Our hoses are designed to withstand the harshest environments, ensuring:

- Fire and earthquake resistance in accordance with AIR 0978/A requirements

- Full traceability from raw material to final product

- Certification compliant with ESPN (Equipment under Nuclear Pressure) regulations

We work in close partnership with key players in the sector, including EDF and UTO, to develop solutions that meet the highest safety standards.

Solutions tailored to nuclear applications:

Our hoses and components are designed for various critical applications:

- Sleeves and compensators to ensure the integrity of hydraulic circuits

- Hoses for engines and backup units, ensuring operational continuity in emergency situations

Our Technical Capabilities:

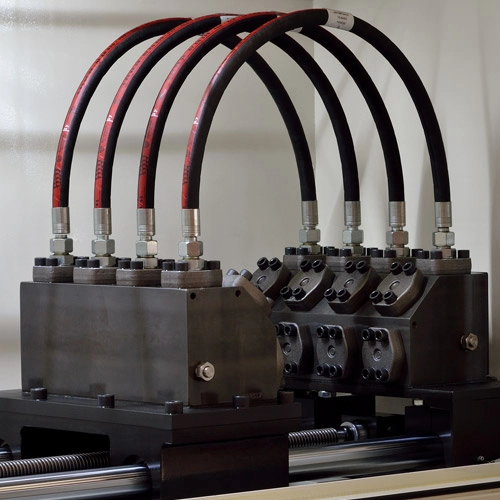

In addition to their human resources and dedicated ERP system, the various entities within the Tecalemit Group are equipped with technical resources tailored to both current and future markets.

Among these resources are:

- 6 crimping machines, including one with 510 tons of force

- 2 hydrostatic test benches

- 1 decontamination bench

- 1 fire testing bench compliant with NF EN 15540

- 2 automatic hose and tube cutting machines

- 1 extrusion line

- 1 4-axis machining center

- 3 lathes, including 2 CNC lathes

- 2 rotating positioners for orbital welding

- 2 ovens for preforming PA12 tubes

- 1 impulse pressure resistance test bench

Tecalemit and the Culture of Nuclear Safety

Tecalemit Flexibles incorporates strict nuclear safety requirements in the manufacturing of its hydraulic hoses, ensuring resistance, reliability, and chemical compatibility with the specific fluids used in the sector.

We apply rigorous qualification and traceability protocols in accordance with current standards such as ESPN (Equipment under Nuclear Pressure).

Our technical department collaborates with nuclear stakeholders to ensure strict control of materials and manufacturing processes.

Specialized testing validates the durability and safety of our products.

We adopt a proactive risk management approach through regular audits, documentation reviews, and ongoing training, ensuring a deeply rooted safety culture in our industrial practices.

With Tecalemit Flexibles, you benefit from technical expertise, quality in compliance with current standards, and full commitment to the safety of your installations.

Our team of professionals is at your service to support your projects.

Shipbuilding

Hydraulic Hoses for the Shipbuilding Industry

High-Performance Hydraulic Hoses

We supply high-performance hydraulic hoses, specifically designed to meet the needs of the shipbuilding industry, especially for the most demanding applications such as offshore vessels, CSOVs, SOVs, OSVs, as well as offshore wind farms and subsea installations.

Our hoses are made from top-grade pipes such as T211 (2SN), T221 (2SC), T911 and T912 (4SP and 4SH), with diameters ranging from 5 to 51 mm, and are designed to withstand hydraulic oil temperatures from -40°C to +100°C.

BV Type Approval Certification

Tecalemit Flexibles holds type approval certificates issued by Bureau Veritas for its crimped hydraulic hoses.

These certificates confirm our products' compliance with the strict requirements of Bureau Veritas Marine & Offshore, ensuring their suitability for installation on steel ships, offshore platforms, warships, and pleasure yachts.

We also manufacture metallic-reinforced hoses certified "BV Marine", as well as stainless steel corrugated metal hoses approved by Bureau Veritas.

These products are designed for maritime and offshore applications, including cruise ships, ferries, RoPax vessels, tugboats, as well as for critical missions such as heavy lifting, mud pumping, marine towing, and cargo transport.

Expertise

The tests conducted as part of these certifications, including fire resistance tests, ensure not only maximum reliability but also enhanced durability and safety.

Our hydraulic hoses are designed to operate in harsh conditions, ensuring easy maintenance and maximum availability — essential criteria for offshore operations or strategic military missions.

As an "open source" manufacturer, we offer customized solutions tailored to the specific needs of each project. We also offer retrofitting and new construction options, while complying with environmental regulations and optimizing both CAPEX and OPEX.

With over a century of experience and recognized technical expertise, Tecalemit Flexibles is your trusted partner for the supply of certified hydraulic hoses.

Whether it's for hybrid propulsion, submarine cable installation, or emergency interventions at sea, our products deliver the performance and reliability you need to successfully execute your complex and demanding projects.

Railway Industry

Hydraulic Hoses for the Railway Industry

Safe Hydraulic Hoses

Safety is a top priority in the railway sector, especially for equipment exposed to fire hazards. All components used in rolling stock must meet strict requirements to ensure the protection of passengers and staff in the event of an emergency.

Tecalemit Flexibles meets these requirements by offering a range of high-performance hydraulic and pneumatic hoses specifically designed for the railway industry and compliant with the EN 45545-2 standard. This unified standard, adopted by all EU countries, ensures optimal hose performance in case of fire by limiting flammability and smoke emission.

Our hoses are perfectly suited for fluid transport systems (oils, fuels, water…), hydraulic and pneumatic braking systems, as well as suction and discharge applications for hydraulic circuits. They provide excellent thermal and chemical resistance, along with high flexibility, essential for complex railway installations.

MANURAIL®: Pneumatic Tubes

As part of our commitment to sustainable and high-performance solutions, Tecalemit Flexibles has developed the MANURAIL® range, consisting of pneumatic tubes made of PA 11 HFFR RILSAN B polyamide.

- Full compliance with EN 45545-2 for maximum fire safety

- Excellent cold impact resistance, ensuring increased reliability in extreme conditions

- 89% bio-based, made from 100% renewable raw materials

- French manufacturing: extruded in Brittany (Pont-l’Abbé) with raw materials sourced from Normandy

Thanks to its thermal, chemical, and mechanical resistance, the MANURAIL® range is ideal for fuel lines, hydraulic and pneumatic circuits, and braking systems of railway vehicles.

Quality Commitment and French Manufacturing

With its expertise and industrial know-how, Tecalemit Flexibles is a trusted partner for railway industry players.

Our technical solutions combine performance, safety, and durability, and are developed to meet the specific needs of each project.

National Defense

Hydraulic Hoses for Defense

Hoses for Radar or Laser Cooling Systems

Specifically designed for radar and laser cooling systems, our hoses ensure optimal fluid circulation, providing efficient and consistent thermal regulation.

Their design minimizes pressure loss while combining lightness, strength, and durability.

Available in a wide range of diameters, they can also be paired with bent rigid tubes to meet the most complex requirements.

Hydraulic Hoses for Embedded Moving Parts

Our hydraulic hoses are specifically engineered for onboard systems in military vehicles, particularly for moving components such as turrets, articulated arms, active suspensions, or stabilization systems.

They withstand high mechanical stresses caused by repeated movements, vibrations, and extreme temperature variations encountered in operational environments.

Their multi-layer construction, combining high-strength metal braids and anti-abrasion outer coatings, ensures excellent resistance to pulsating pressure and long service life under severe conditions.

The hoses are also compatible with a wide range of hydraulic fluids (including synthetic fluids used in harsh environments) and can be equipped with specific fittings (swivel ends, elbow connectors, etc.) to adapt to complex integration configurations.

Fuel Hoses and Tubes for Military Ground Vehicles

Our fuel hoses and tubes are specially developed to withstand the harsh conditions of military ground vehicles (armored, logistics carriers, tactical vehicles).

Designed to operate in extreme environments, they resist thermal shocks, prolonged vibrations, hydrocarbon splashes, and exposure to common chemicals on the battlefield.

Their structure includes an inner tube compatible with all types of military fuels (diesel, F-34, JP-8, etc.), one or more textile or metal reinforcement braids for pressure resistance, and an outer coating ensuring fire resistance in compliance with AIR 0978A standard.

Design and Industrialization

At Tecalemit Flexibles, we manage the entire product lifecycle, from initial design to mass production, ensuring full compliance with customer requirements and applicable standards:

- Rapid prototyping and solution validation.

- Development of specific plans and detailed manufacturing schedules to ensure deadlines and operation traceability.

- Implementation and management of associated technical documentation: bills of materials and drawings, FAI files, quality plans (PQR), assembly procedures, installation and maintenance manuals...

Quality Management System

Our quality management system is structured, robust, and focused on continuous improvement to ensure compliant, reliable products suited for the most demanding environments.

It relies on proven tools for problem-solving and risk prevention:

- QRQC (Quick Response Quality Control): a field management method for reactive and structured handling of non-conformities as they occur, promoting a culture of quick and collective resolution.

- FMEA (Failure Modes, Effects, and Criticality Analysis): used from the design phase to anticipate risks, enhance product reliability, and secure processes.

- 8D Method: a structured tool for addressing complex quality incidents, identifying root causes, implementing lasting corrective actions, and capitalizing on lessons learned.

- Defect tracking in PPM (Parts Per Million): a key performance indicator for precisely measuring delivered quality, with demanding targets aligned with high-level industrial standards (aerospace, defense, railway...).

Our quality system is certified to ISO 9001, with rigorous process management and full traceability across the entire production chain.

Contact Us![]()

Technical Support and Guidance

Tecalemit Flexibles

31, Route de Combrit 29120 Pont-l’Abbé

Phone: +(33) 02 98 82 48 48

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR