An impulsion bench with exceptional capacities

Our company has just acquired a hydraulic pressure impulsion bench for testing our hydraulic connection hoses.

It complements our hose control equipment: hydrostatic test bench, fire test bench, traction bench, pollution control bench and a cyclic fatigue bench.

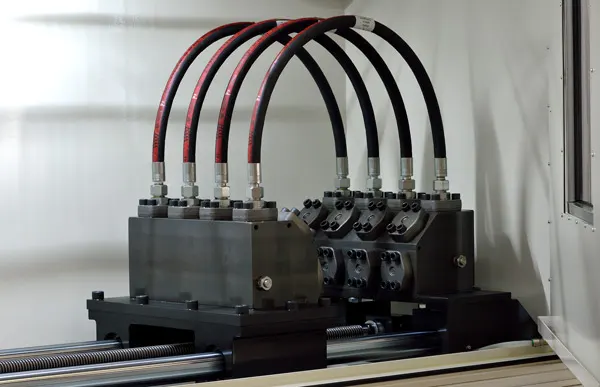

This bench performs the pressure impulsion tests of hydraulic components such as hoses and pipes, fittings, valves and quick fittings according to SAE J343 and ISO 6803 specifications.

The test bench is divided into:

• Hydraulic system with main tank, hydraulic unit and auxiliary tank for the test fluid temperature control system

• Electrical system with IP55 protection rating compliant with EN60529

• Industrial PC with 19” touch screen, inserted into the structure. The automation of the test is carried out with the help of custom software, allowing the operator to configure the ON and OFF phases, regulate the pressure impulsion, count the cycles with automatic shutdown in the presence of a fluid leakage or component failure, control the temperature and also monitor the waveform.

The PLC software controls and manages operations, displays the graphical and numerical trend of the test, stores instructions and prints the final test report.

TECHNICAL DATA

• Pressure wave impulsion according to SAE J343, ISO 6803

• Maximum test pressure 1000 bar (14504 PSI)

• Minimum test pressure 80 bar (1160 PSI)

• Displacement per impulsion 230 cm3 (14 cu.in)

• Maximum test frequency 1 Hz

• Maximum oil temperature 150°C (302°F)

• No. 2 manifolds, one of which is adjustable (by external steering wheel) up to a distance of 1200 mm (47.24 inches) equipped with No. 24 ½” connections placed at 0° - 45° - 90°

• Performance test in accordance with SAE J343

• No.1 pipe 2” R13

• No. 2 pipes 1” 1/2 R15

• No. 4 pipes 1" 4SH

SAFETY DEVICES

• Locks prevent running the test with the hatch open

• Openings to display tested items, with safety goggles

• Emergency button

• Automatic stop in case of any malfunction of the bench

CURRENT SOURCE

• Standard voltage 400 V - 50 Hz - three phase (different voltage on request)

• Motor power of 30 kW

• Industrial cooling water T≤ 15°C

WEIGHT AND SIZE

• Weight without oil 1800 Kg (3960 lbs)

• 3000x1600x2000 mm (118x63x78 inches) (WxDxH)

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR