Steel industry delivery rubber hoses

| 853 | |

| ||

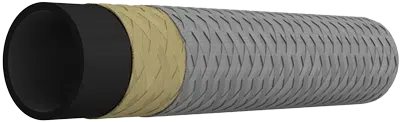

Hose 853 is a high quality hose, intended for cooling circuits of induction furnaces, or for applications requiring a high electrical resistance of the flexible pipe.

Its aging resistance is excellent.

It can be used for protection of electrical cables.

Technical specifications :

Inner tube : white EPDM rubber

Reinforcement : textile plies

Inner tube : blue EPDM rubber

Outer finish : fine tape wrapped

Temperature : -40°C to +170° C.

Production lengths : 40 meters

Colour : blue

Marking : MARKING : TECALEMIT - PART N° - BATCH N°

| Part n° | Inner diameter | Outer diameter | Wall thickness | Working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 853 8 | 8 | 5/16” | 17 | 4.5 | 15 | 50 | 60 | 0,3 |

| 853 10 | 10 | 3/8” | 18 | 4,0 | 15 | 50 | 90 | 0,3 |

| 853 13 | 13 | 1/2” | 22 | 4.5 | 15 | 50 | 110 | 0,4 |

| 853 16 | 16 | 5/8” | 28 | 6.0 | 15 | 50 | 140 | 0,6 |

| 853 19 | 19 | 3/4” | 31 | 6.0 | 15 | 50 | 160 | 0,7 |

| 853 25 | 25 | 1” | 37 | 6.5 | 15 | 50 | 210 | 0,9 |

| 853 30 | 30 | 1”3/16 | 42 | 6.0 | 15 | 50 | 270 | 1,0 |

| 853 32 | 32 | 1”1/4 | 45 | 6.5 | 15 | 50 | 280 | 1,1 |

| 853 35 | 35 | 1”3/8 | 48 | 6.5 | 15 | 50 | 300 | 1,2 |

| 853 38 | 38 | 1”1/2 | 51 | 6.5 | 15 | 50 | 350 | 1,3 |

| 853 40 | 40 | 1”9/16 | 53 | 6.5 | 15 | 50 | 380 | 1,4 |

| 853 42 | 42 | 1”5/8 | 55 | 6.5 | 15 | 50 | 400 | 1,5 |

| 853 50 | 50 | 2” | 64 | 7.0 | 15 | 50 | 450 | 1,9 |

| 853 60 | 60 | 2”3/8 | 74 | 7.0 | 15 | 50 | 520 | 2,2 |

| 853 63 | 63 | 2”1/2 | 78 | 7.5 | 15 | 50 | 550 | 2,5 |

| 853 70 | 70 | 2”3/4 | 86 | 8.0 | 15 | 50 | 680 | 2,9 |

| 853 76 | 76 | 3” | 92 | 8.0 | 15 | 50 | 700 | 3,1 |

| 853 90 | 90 | 3”5/8 | 104 | 8.5 | 15 | 50 | 820 | 3,9 |

| 853 100 | 100 | 4” | 118 | 8.5 | 15 | 50 | 900 | 4,6 |

Possible end-fittings : Threaded, Flange

| 854 |

| |

Hose 854 is intended for the discharge of blast furnace door cooling water as well as applications where hose resistance to ambient temperatures is necessary.

It can also be used as a sheath to protect cables and other hoses from heat radiation.

This high quality hose is electrically insulating.

It can be equipped with swaged end-fittings.

Technical specifications :

Inner tube : white insulating EPDM rubber

Reinforcement : textile plies

Outer cover : white auto-extinguishing insulating neoprene rubber with vulcanised glass fibre coating

Inner tube working temperature : -40°C to +120°C

Outer tube working temperature : +540°C, peaks to 1000°C

Outer finish : glass fibre

Production lengths : 40 meters

Colour : white

Marking : none

| Part n° | Inner diameter | Outer diameter | Wall thickness | Working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 854 13 | 13 | 1/2” | 24 | 5.5 | 15 | 50 | 100 | 0.4 |

| 854 16 | 16 | 5/8” | 29 | 6.5 | 15 | 50 | 120 | 0.5 |

| 854 19 | 19 | 3/4” | 32 | 6.5 | 15 | 50 | 140 | 0.7 |

| 854 25 | 25 | 1” | 38 | 6.5 | 15 | 50 | 180 | 0.8 |

| 854 30 | 30 | 1” 3/16 | 44 | 7.0 | 15 | 50 | 210 | 1.0 |

| 854 32 | 32 | 1” 1/4 | 47 | 7.5 | 15 | 50 | 230 | 1.1 |

| 854 35 | 35 | 1” 3/8 | 50 | 7.5 | 15 | 50 | 240 | 1.3 |

| 854 38 | 38,1 | 1” 1/2 | 53 | 7.5 | 15 | 50 | 260 | 1.4 |

| 854 40 | 40 | 1” 9/16 | 55 | 7.5 | 15 | 50 | 280 | 1.5 |

| 854 42 | 42 | 1” 5/8 | 57 | 7.5 | 15 | 50 | 300 | 1.6 |

| 854 45 | 45 | 1” 3/4 | 60 | 7.5 | 15 | 50 | 320 | 1.7 |

| 854 50 | 50,8 | 2” | 66 | 8.0 | 15 | 50 | 350 | 2.0 |

| 854 53 | 53 | - | 73 | 10 | 15 | 50 | 400 | 2.5 |

| 854 57 | 57 | 2"1/4 | 73 | 8 | 15 | 50 | 500 | 2.2 |

| 854 60 | 60 | 2” 3/8 | 76 | 8.0 | 15 | 50 | 420 | 2.2 |

| 854 65 | 65 | 85 | 10.0 | 15 | 50 | 440 | 2.8 | |

| 854 70 | 70 | 2” 3/4 | 87 | 8.5 | 15 | 50 | 490 | 2.9 |

| 854 76 | 76,2 | 3” | 94 | 9.0 | 15 | 50 | 530 | 3.0 |

| 854 90 | 90 | 3” 5/8 | 113 | 11.5 | 15 | 50 | 630 | 5.0 |

| 854 100 | 101,6 | 4” | 120 | 10.0 | 15 | 50 | 700 | 5.2 |

| 854 127 | 127 | 5” | 147 | 10.0 | 15 | 50 | 780 | 7.2 |

| 854 140 | 140 | 5” 1/2 | 160 | 10.0 | 15 | 50 | 900 | 8.0 |

| 854 150 | 152,4 | 6” | 174 | 11.0 | 15 | 50 | 1050 | 8.6 |

| 854 160 | 160 | 6” 5/16” | 180 | 10.0 | 15 | 50 | 1200 | 9.7 |

| 854 200 | 203,2 | 8” | 228 | 12.0 | 15 | 50 | 1400 | 14.0 |

Possible end-fittings : Male threaded, Flange, Cam type

See also 855

| 855/856 | |

855 - metal spiral 856 - polyester spiral | ||

Hose 855 is intended for suction and delivery of water for cooling blast furnace doors and inapplications where the outer cover must resist ambient temperatures.

Its metal spiral gives excellent bend radius.

This hose can also have a galvanised steel braid sheath to mechanically protect the glass fibre coating.

It can be equipped with swaged end-fittings in all diameters.

Hose 856 has a polyester spiral which allows it to be used in electromagnetic environments.

Technical specifications :

Inner tube : white insulating EPDM rubber

Reinforcement : textile plies and metal spiral

Outer cover : white insulating fire-resistant CR rubber with vulcanised glass fibre coating

Inner tube working temperature : - 40°C to +120°C

Outer tube working temperature : + 540°C, peaks to 1000°C

Outer finish : glass fibre

Production lengths : 40 meters

Colour : white

Marking : none

| Part n° | Inner diameter | Outer diameter | Wall thickness | Pression de service | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 855 30 | 30 | 1” 3/16 | 45 | 7.5 | 15 | 50 | 130 | 1,0 |

| 855 32 | 32 | 1” 1/4 | 47 | 7.5 | 15 | 50 | 180 | 1,2 |

| 855 35 | 35 | 1” 3/8 | 51 | 8 | 15 | 50 | 200 | 1,3 |

| 855 38 | 38 | 1” 1/2 | 54 | 8 | 15 | 50 | 220 | 1,4 |

| 855 40 | 40 | 1” 9/16 | 56 | 8 | 15 | 50 | 230 | 1,7 |

| 855 42 | 42 | 1” 5/8 | 58 | 8 | 15 | 50 | 250 | 1,8 |

| 855 50 | 50,8 | 2” | 66 | 8 | 15 | 50 | 280 | 2,2 |

| 855 60 | 60 | 2” 3/8 | 76 | 8 | 15 | 50 | 300 | 2,4 |

| 855 63,5 | 63,5 | 2” 1/2 | 81 | 8.5 | 15 | 50 | 350 | 2,5 |

| 855 70 | 70 | 2” 3/4 | 89 | 9.5 | 15 | 50 | 380 | 2,6 |

| 855 76 | 76,2 | 3” | 95 | 9.5 | 15 | 50 | 400 | 3,4 |

| 855 90 | 90 | 3” 5/8 | 109 | 9.5 | 15 | 50 | 500 | 4,0 |

| 855 100 | 100 | 4” | 121 | 10.5 | 15 | 50 | 550 | 4,5 |

| 855 110 | 110 | 4”11/32 | 130 | 10 | 15 | 50 | 670 | 5,5 |

| 855 127 | 127 | 5" | 147 | 10 | 15 | 50 | 700 | 6,0 |

| 855 150 | 152,4 | 6” | 174 | 10 | 15 | 50 | 750 | 8,0 |

| 855 200 | 203,2 | 8” | 236 | 17 | 15 | 50 | 1000 | 18,2 |

Possible end-fittings : Male threaded, Flange, Cam type

See also 854

| VKI | |

| ||

This high quality hose is comprised of an inner tube compatible with oils up to 180°C (it is used for lubrication of automobile turbo-compressors), covered with an aramide braid acting as a thermal shield (for use in hot environments), then covered with a stainless steel braid which has two functions : mechanical protection of the aramide braid and improvement in pressure resistance.

This hose can convey fluids as per the chemical compatibility chart.

Please consult us for dynamic pressure use.

Technical specifications :

Inner tube : FKM synthetic rubber

Reinforcement : 1 aramide braid

Outer cover : 1 stainless steel 316 braid

Outer finish : shiny

Inner tube working temperature : +35°C to +180°C in 300°C continuous environment

Production lengths : 22 meters

Colour : stainless steel

Marking : none

| Part n° | Mod. | Inner diameter | Outer diameter | Working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | bar | bar | mm | kg/m | ||

| 993 01 07 | 3 | 5 | 3/16” | 11 | 207 | 827 | 51 | 0,15 |

| 993 24 15 | 4 | 6,4 | 1/4” | 14,1 | 190 | 759 | 76 | 0,29 |

| 993 24 16 | 5 | 8 | 5/16” | 14,5 | 172 | 690 | 80 | 0,24 |

| 993 24 14 | 6 | 9,5 | 3/8” | 15,5 | 155 | 621 | 80 | 0,30 |

| 993 24 17 | 8 | 12,7 | 1/2” | 19,5 | 138 | 552 | 102 | 0,34 |

| 993 24 18 | 10 | 16 | 5/8” | 23 | 103 | 414 | 127 | 0,42 |

| 993 24 19 | 12 | 19 | 3/4” | 26,6 | 86 | 345 | 241 | 0,48 |

| 993 38 03 | 16 | 25,4 | 1” | 35,2 | 69 | 276 | 305 | 0,76 |

Possible end-fittings : Hydraulic type

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR