Protection sheath for rubber hoses & electrical cables

Protecalan woven sheath

The Protecalan woven sheath is mainly used on secured hydraulic hoses, but it is also suited to the protection of flexible electric cables and all types of flexible hoses.

Technical specifications :

Sheath: Woven with high antistatic tenacity

Maximum operation temperature: 110°C

Colour : Black.

Marking : Protecalan

| Sheath | |

| Part n° | Dia. sheath (mm) |

| M7853000070036 | 41 |

| M7853000070045 | 51 |

| M7853000070057 | 64 |

| M7853000070070 | 83 |

| M7853000070075 | 95 |

| M7853000070101 | 109 |

137

Flexible protection sheath

for electrical cables and hoses

Sheathing REF 137 is intended to protect flexible electrical cables and hoses.

Its qualities are its great flexibility, its light weight and its thin wall.

Its black rubber outer wrapped finish is abrasion and weather resistant.

Produced on mandrils, it is available in a wide range of diameters.

Technical specifications :

Inner tube : beige rubber covered textile plies

Outer finish : sbr/epdm rubber

Outer finish : wrapped

Production lengths : 40 metres

Colour : black

Marking : none

| Part n° | Inner diameter | Outer diameter | Wall thickness | Working pressure | Burst pressure | Bend radius | Weight | |

| mm | Inch | mm | mm | bar | bar | mm | kg/m | |

| 137 19 | 19 | 3/4” | 22 | 1.5 | - | - | - | 0,13 |

| 137 20 | 20 | 3/4" | 23 | 1.5 | - | - | - | 0,15 |

| 137 22 | 22 | 7/8" | 26 | 2.0 | - | - | - | 0,15 |

| 137 25 | 25,4 | 1” | 28 | 1.5 | - | - | - | 0,14 |

| 137 28 | 28,5 | 1”1/8 | 31 | 1.5 | - | - | - | 0,18 |

| 137 30 | 30 | 1”1/4 | 34 | 1.5 | - | - | - | 0,26 |

| 137 35 | 35 | 1”3/8 | 38 | 1.5 | - | - | - | 0,22 |

| 137 38 | 38 | 1"1/2 | 41 | 1.5 | - | - | - | 022 |

| 137 40 | 40 | 1"9/16 | 44 | 2.0 | - | - | - | 0,30 |

| 137 44,5 | 44,5 | - | 48,5 | 1,75 | - | - | - | 0,33 |

| 137 45 | 45 | 1”3/4 | 48,5 | 1.5 | - | - | - | 0,38 |

| 137 51 | 50,8 | 2” | 54 | 1.5 | - | - | - | 0,32 |

| 137 54 | 54 | 2"3/4 | 57 | 1.5 | - | - | - | 0,40 |

| 137 57 | 57,1 | 2”1/4 | 60 | 1.5 | - | - | - | 0,33 |

| 137 60 | 60 | 2”3/8 | 63 | 1.5 | - | - | - | 0,42 |

| 137 63 | 63,5 | 2”1/2 | 66 | 2.0 | - | - | - | 0,31 |

| 137 70 | 70 | 2”3/4 | 74 | 2.0 | - | - | - | 0,50 |

| 137 76 | 76,2 | 3” | 80 | 2.0 | - | - | - | 060 |

| 137 90 | 90 | 3”9/16 | 95 | 2.5 | - | - | - | 0,70 |

| 137 100 | 101,6 | 4” | 105 | 2.5 | - | - | - | 0,80 |

GA

Silicone coated fibre glass sheathing

The GA sheathing is a mineral fibre braided sheath coated with fire-resistant silicone rubber.

It is intended to protect hoses or cables, with the fibre braid ensuring thermal protection and the silicone coating ensuring impermeability and resistance to flames.

Moreover, the silicone outer cover mechanically protects the braid and increases thermal protection.

Destructive tests have indicated a life span of 15 minutes at 1100°C and one minute at 1500°C. The GNS sheathing can be supplied in thicknesses of 4mm in any diameter for extreme applications.

It does not contain asbestos.

0,9 mm thick

Technical characteristics for the 0.9mm thick sheath:

Temperature class: C

Temperature in continuous operation: from -60°C to +250°C. Peaks at +290°( a few hours)

Dielectric strength: 1.5 to 15kV

Flame resistance: self-extinguishable

Good mechanical resistance

Good UV resistance

Resistant to oil from transducers

Good compatibility with impregnation varnishes of the same class

Good resistance to soldering iron

Good resistance to liquid fuels: no decomposition

Halogen-free

Impervious

Very flexible

Standards:

Compliant with Directive RoHS 2011 /65/EU

F1 and 12 as per standards NF F 16-101 /16-102 and STM S-001

NF EN 60695-2-10 (05-2001)

NF EN 60695-2-11 (07-2001)

NF EN 60684-1 (10-2003)

NF EN 60684-2 (07-2012)

NF EN (CEl) 60684 - 3 pages 400 to 402 (02 /2003)

Option: UL 1441 1 CSA C22.2 N°198.3 approval

SCS UL: Passed the flame non-spread test UUVW7, vertical sample

File W: UZIQ2- E23S042

SCS7KV: Grade A, silicon coated fiberglass braid, 200°C nominal, 600 Volts

File W: UZFT2/8- E7 94299

Other colours available on request : Green, blue, red, orange, yellow, white, grey.

| Part n° | Inner diameter | Wall thickness | Internal diameter tolerance | Packaging (m) | |

| mm | mm | mm | Crowns | Tambours | |

| 8607060 | 6 | 0,9 | 0,5 | 100 | |

| 8607061 | 8 | 0,9 | 0,5 | 100 | |

| 8607062 | 10 | 0,9 | 0,5 | 100 | |

| 8607063 | 12 | 0,9 | 0,5 | 100 | |

| 8607064 | 14 | 0,9 | 0,5 | 50 | |

| 8607065 | 16 | 0,9 | 1 | 50 | |

| 8607066 | 18 | 0,9 | 1 | 50 | |

| 8607067 | 20 | 0,9 | 1 | 50 | |

| 8607068 | 22 | 0,9 | 1 | 30 | |

| 8607069 | 25 | 0,9 | 1 | 30 | |

| 8607071 | 30 | 0,9 | 1 | 30 | |

2 mm thick

Technical characteristics for the 2 mm thick sheath :

Temperature in continuous operation: from -60°C to +250°C

Peaks at : > 1000°C

Flame resistance: self-extinguishable

Good mechanical resistance

Good UV resistance

Resistant to oil from transducers

Good compatibility with impregnation varnishes of the same class

Good resistance to soldering iron

Good resistance to liquid fuels: no decomposition

Halogen-free

Impervious

Very flexible

Standards:

Compliant with Directive RoHS 2011 /65/EU

- NF EN 60695-2-10 (05-2001)

- NF EN 60695-2-11 (07-2001)

- NF EN 60684-1 (1 0-2003)

- NF EN 60684-2 (07-2012))

- NF EN (CEl) 60684 - 3 pages 400 to 402 (02/2003)

Colours and Packaging :

- Diamètres fabriqués: from 4 to 45 mm

- Couleur standard : Red

- Other colours : On request

- Standard packaging: Reels or crowns

| Part n° | Inner diameter | Wall thickness | Internal diameter tolerance | Packaging (m) | |

| mm | mm | mm | Crowns | Reels | |

| 8607081 | 6 | 2 | 0,5 | 100 | |

| 8607082 | 8 | 2 | 0,5 | 100 | |

| 8607083 | 10 | 2 | 0,5 | 50 | |

| 8607084 | 12 | 2 | 0,5 | 50 | |

| 8607085 | 14 | 2 | 0,5 | 50 | |

| 8607086 | 16 | 2 | 0,5 | 50 | |

| 8607087 | 18 | 2 | 1 | 50 | |

| 8607088 | 20 | 2 | 1 | 50 | |

| 8607089 | 22 | 2 | 1 | 30 | |

| 8607090 | 25 | 2 | 1 | 30 | |

| 8607091 | 30 | 2 | 1 | 30 | |

| 8607092 | 32 | 2 | 1 | 30 | |

| 8607072 | 35 | 2 | 1 | 30 | |

| 8607093 | 38 | 2 | 1 | 30 | |

| 8607073 | 40 | 2 | 1 | 30 | |

| 8607074 | 45 | 2 | 1 | 30 | |

4 mm thick

Technical characteristics for the 4 mm thick sheath:

Temperature in continuous operation: from -60°C to +260°C

Peaks at :

- 30 min to 800°C

- 15 min to 1100°C

- 1 min to 1500°C

Flame resistance: self-extinguishable

Good mechanical resistance

Good UV resistance

Resistant to oil from transducers

Good compatibility with impregnation varnishes of the same class

Good resistance to soldering iron

Good resistance to liquid fuels: no decomposition

Halogen-free

Impervious

Very flexible

Standards:

Compliant with Directive RoHS 2011/65/EU

- F1 and 12 as per standards NF F 16-101/16-102 and STM 5-001

- NF EN 60695-2-10 (05-2001)

- NF EN 60695-2-11 (07-2001)

- NF EN 60684-1 (10-2003)

- NF EN 60684-2 (07-2012)

- NF EN (CEl) 60684-3 pages 400 to 402 (02/2003)

Colours and Packaging :

- Diamètres fabriqués: from 8 to 102 mm

- Couleur standard : Red

- Other colours : On request

- Standard packaging: Reels or crowns

| Part n° | Inner diameter | Wall thickness | Internal diameter tolerance | Packaging (m) | |

| mm | mm | mm | Crowns | Reels | |

| 8607005 | 8 | 4 | 0,5 | 100 | |

| 8607008 | 10 | 4 | 0,5 | 100 | |

| 8607007 | 13 | 4 | 0,5 | 90 | |

| 8607011 | 16 | 4 | 1 | 85 | |

| 8607012 | 19 | 4 | 1 | 80 | |

| 8607019 | 22 | 4 | 1 | 75 | |

| 8607021 | 25 | 4 | 1 | 70 | |

| 8607025 | 32 | 4 | 1 | 50 | |

| 8607029 | 38 | 4 | 1 | 40 | |

| 8607033 | 45 | 4 | 1,5 | 30 | |

| 8607037 | 51 | 4 | 1,5 | 30 | |

| 8607038 | 57 | 4 | 1,5 | 30 | |

| 8607039 | 60 | 4 | 1,5 | 30 | |

| 8607040 | 64 | 4 | 1,5 | 30 | |

| 8607032 | 70 | 4 | 2 | 30 | |

| 8607043 | 76 | 4 | 2 | 30 | |

| 8607046 | 80 | 4 | 2 | 15 | |

| 8607047 | 89 | 4 | 2 | 15 | |

| 8607049 | 102 | 4 | 2 | 15 | |

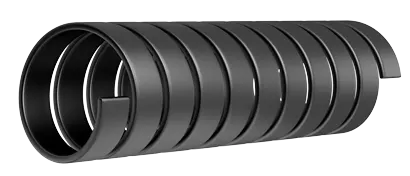

GSP

Spiral guard for hydraulic hoses & electrical cables

The spiral girdle made from polyethylene (PE) is a very flexible protective girdle and is mainly used in bays(berries) waiters(servers), electric cupboards, the office automation, the automobile, the public works and the aviation.

His(Her,Its) spiral structure allows him(her) to be rolled up around cables or around already put flexible hoses.

She(It) is reusable, resistant in most of the chemicals

His(Her,Its) temperature of continuous service(department) is situated between-20°C in + 60°C.

Technical specifications :

Gaine : Polyethylene

Outer finish : Spiral

Temperature : -20°C à + 60°C

Colour : Black, other colours & lengths upon request

Marking : none

| Part n° | Section | Inner diameter | Outer diameter | Wall thickness | Coil tightness | Length min. | Weight |

| mm | mm | mm | mm | m | kg/m | ||

| 8607855 | 7,5 | 10 | 1,25 | 9 | 20 | 0,032 | |

| 8607849 | 9,5 | 12 | 1,25 | 11 | 20 | 0,039 | |

| 8607862 | 13 | 16 | 1,5 | 15 | 20 | 0,064 | |

| 8607856 | 16 | 20 | 2 | 22,5 | 20 | 0,106 | |

| 8607850 | 20 | 25 | 2,5 | 28 | 20 | 0,166 | |

| 8607851 | 24 | 29 | 2,5 | 30 | 20 | 0,196 | |

| 8607852 | 27 | 32 | 2,5 | 30 | 10 | 0,217 | |

| 8607857 | 30 | 35 | 2,5 | 28 | 10 | 0,239 | |

| 8607854 | 35 | 40 | 2,5 | 28 | 10 | 0,276 | |

| 8607859 | 16X2 | 45 | 50 | 3 | 28 | 25 | 0,85 |

| 8607860 | 16X2 | 50 | 60 | 5 | 28 | 20 | 0,9 |

| 8607861 | 16X2 | 60 | 70 | 5 | 32 | 20 | 1,2 |

| 8607863 | 25X3 | 65 | 75 | 5 | 32 | 20 | 1,3 |

| 8607864 | 25X3 | 75 | 85 | 5 | 35 | 10 | 1,5 |

| 8607865 | 16X2 | 80 | 90 | 5 | 35 | 10 | 1,55 |

| 8607866 | 25X3 | 100 | 110 | 5 | 35 | 10 | 1,65 |

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR