Protecalan secured hoses for the protection of operators

Protecalan system is the only patented system meeting both requirements of standard EN ISO 4413, that is to say, protecting people against the whipping of the hose and against fluid projections.

As such, thanks to its sheath and its attached cable, it is in itself a double protection.

Although it is of limited effectiveness in the event of fire and bursting of the tip, it has many advantages over the shield screen which is difficult or even impossible to install on equipment in motion and which is of no efficiency in a technical intervention during operation, and does not protect the machine from the whipping of the hose.

We can add that implementing a Protecalan secured hose is easy and does not required special tools. It is easy to adapt onto existing installations and bears no constraints on equipment in motion.

To conclude, the presence of the sheath can, when hoses are highly exposed to atmospheric agents, significantly increase the life of the outer cover and consequently the hose itself, protecting it from UV rays and ambient ozone which are major sources of aging.

Presentation

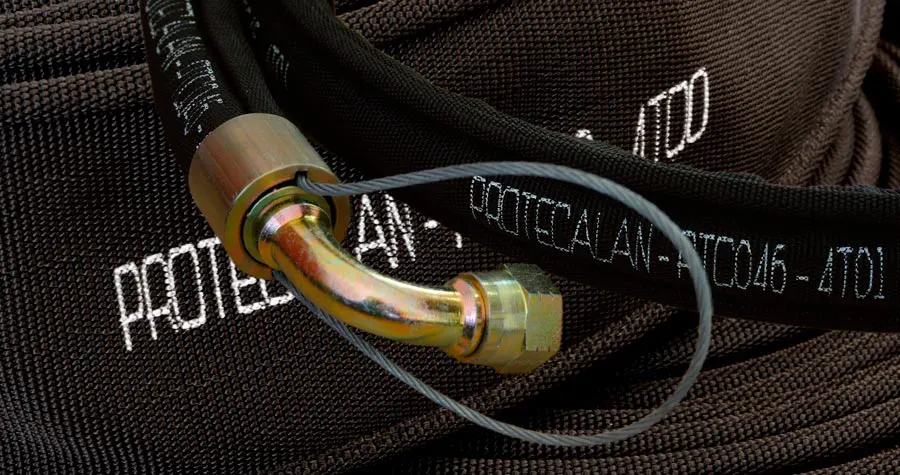

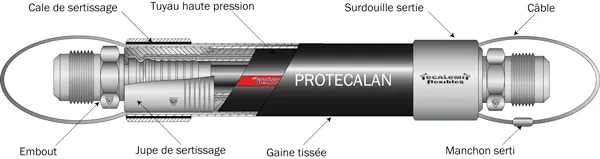

Presentation of the Protecalan system :

The Protecalan system consists of a steel cable and its sleeve, a circular braided sheath with two longitudinal seams for the passage of the cable, two crimping bushing covers and four rubber blocks.

First the hose is fed inside the woven sheath which has been cut at an appropriate length to allow the movements of the hose.

Then the cable – of a length calculated as indicated in our assembly procedure – is successively inserted in both channels intended for this purpose in the woven sheath. It is then crimped in a sleeve so that it constitutes a loop enclosing the hose over the entire length.

The bushing covers, fitted with a space for the passage of cables, are then positioned at the level of the crimping bushings of the hose, thus covering the tip of the sheath.

The four blocks, obtained from a length of rubber, are inserted two by two in the recesses created in the bushing cover by the two folds of the sheath.

To finish, the bushing covers are crimped according to a crimping table taking the type of hose into account:

T111, T211,T911, T912 or T1310 for diameters from 3/16’’ (4,8 mm) to 2’’(50,8mm).

All these elements get together to create a Protecalan secured hose.

Installation

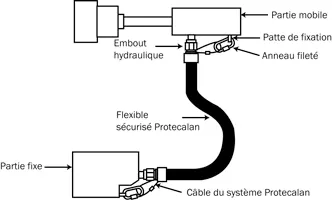

Installation of the secured Protecalan hose:

The hose is connected hydraulically, in the usual manner, with its tips with swivel nuts or flanges.

It is then necessary to weld or screw the fitting flanges on the machine, near the end of the hose.

A shackle or a threaded attachment ring will then be necessary to clamp the circular cable of the secured Protecalan hose to the installation.

Composants

Composants of the secured Protecalan hose:

|

| |||||||||||||||||||||||

|

| ||||||||||||||||||||||

|

| ||||||||||||||

| |||||||||||||||||

|

| |||||||||||||||||||||||

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR