Construction of connectors

All “S” and “SD” inserts are produced homogeneously in the ultra-modern Cast factories in Turin. The quality and repeatability levels are very high.

For each part, traceability is endured by an engraved code, as follows:

Cast – T 5 CE 50 48

T indicates the production plant, 5 the year of manufacturing, CE manufactured in Europe, 50 the type of steel, 48 the cast number.

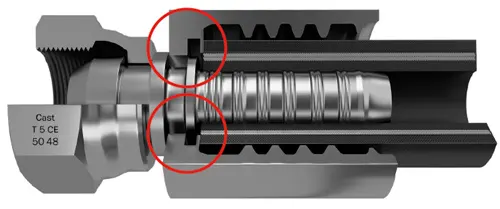

Besides, the internal shape of the crimping sleeve guarantees, regardless of the diameter and the series, the correct position of the pipe relative to the connector.

Easier fitting:

To start with, the pipe is positioned effortlessly in the correct position on an internal stop in the crimping sleeve.

The nipple is then inserted quickly and right down to its mechanical stop, without any risk of error.

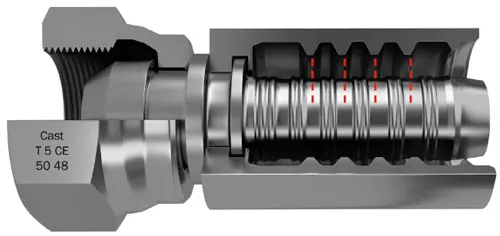

Improved tightness:

The risk of seepage disappears thanks to a perfect match between the internal shape of the crimping sleeves and that of the nipple.

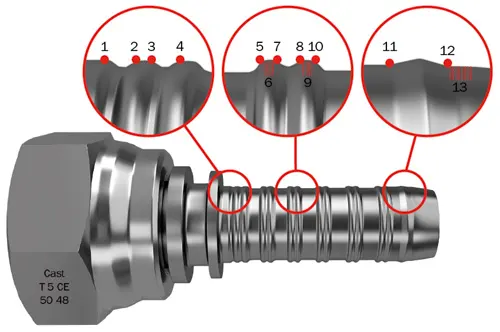

The shape of the nipple has 3 different kinds of sealing points and pressure resistance that are ideally positioned. First, the 1-2-3-4 sealing points required for very difficult applications to prevent seepage.

Then, the series of pressure resistance surfaces, 6 and 9, surrounded by sealing points 5-7-8-10.

And finally, facing the last notch of the skirt that is less pronounced than the others, a cylindrical sealing shape that cannot alter the inner tube of the pipe.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer.

Department specialized in manufacturing high-quality industrial hoses for fluid transfer. Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms.

Specialist in the manufacturing of hydraulic hoses, extrusion of pneumatic tubes, and production of thermoplastic preforms. Wide selection of industrial and hydraulic hoses and fittings in the Paris region.

Wide selection of industrial and hydraulic hoses and fittings in the Paris region. Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Machining of fittings for industrial and hydraulic hoses, crimped ferrules, and stainless steel corrugated hoses.

Type approval certificates for hydraulic hoses

Type approval certificates for hydraulic hoses Development of the company and its infrastructures

Development of the company and its infrastructures Tecalemit Flexibles strengthens its presence in the energy sector

Tecalemit Flexibles strengthens its presence in the energy sector A pulse bench with exceptional capabilities

A pulse bench with exceptional capabilities Hose type approvals for the transport of hazardous materials

Hose type approvals for the transport of hazardous materials A depollution bench of our design

A depollution bench of our design BV type certification for fire resistant hoses

BV type certification for fire resistant hoses DE

DE  ES

ES  EN

EN  FR

FR